Method for synthesizing B-beta-heteroatom molecular sieve

A heteroatomic molecular sieve and crystal seed technology, applied in the field of catalytic chemistry, can solve the problems of large particle size of solid products, long crystallization time, low production efficiency, etc., and achieve easy mass production, reduced product particle size, and crystallization time. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

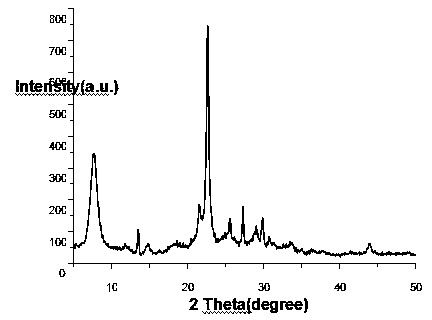

[0059] Combine 0.48g borax, 0.15g NaOH, 0.93g NH 4 F was dissolved in 6.85g deionized water, 29.46g TEAOH was added to the above solution under mechanical stirring, after the solids were completely dissolved, 0.27g B-β molecular sieve seeds and 9.0g white carbon black were added to the above solution, continue After stirring for 2.5 h, put the above gel into a stainless steel reactor with PTFE lining, crystallize at 150℃ for 3 d, cool, centrifuge, wash, dry at 100℃ overnight, and then pass 540℃ The raw powder of B-β molecular sieve is obtained after roasting for 3 h. The solid yield is 80%. The characterization results are attached figure 1 , 2 .

Embodiment 2

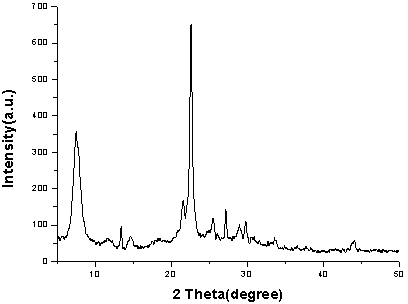

[0061] Combine 0.48g borax, 0.15g NaOH, 0.74g NH 4 F was dissolved in 6.85g deionized water, 29.46g TEAOH was added to the above solution under mechanical stirring, after the solids were completely dissolved, 0.27g B-β molecular sieve seeds and 9.0g white carbon black were added to the above solution, continue After stirring for 2.5 h, put the above gel into a stainless steel reactor with PTFE lining, crystallize at 150℃ for 3 d, cool, centrifuge, wash, dry at 100℃ overnight, and then pass 540℃ The raw powder of B-β molecular sieve is obtained after roasting for 3 h. The solid yield is 85%. The characterization results are attached image 3 , 4 .

Embodiment 3

[0063] Combine 0.48g borax, 0.15g NaOH, 0.56g NH 4 F was dissolved in 6.85g deionized water, 29.46g TEAOH was added to the above solution under mechanical stirring, after the solids were completely dissolved, 0.27g B-β molecular sieve seeds and 9.0g white carbon black were added to the above solution, continue After stirring for 2.5 h, put the above gel into a stainless steel reactor with PTFE lining, crystallize at 150℃ for 3 d, cool, centrifuge, wash, dry at 100℃ overnight, and then pass 540℃ The raw powder of B-β molecular sieve is obtained after roasting for 3 hours. The solid yield is 67%. The characterization results are attached Figure 5 , 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com