Permanent magnetic strontium-ferrite material powder and preparation method thereof

A technology of strontium ferrite and material powder, which is applied in the field of permanent magnet strontium ferrite material powder and its preparation, can solve the problems of reducing the magnetic properties of ferrite, and achieve excellent magnetic properties, simple process, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

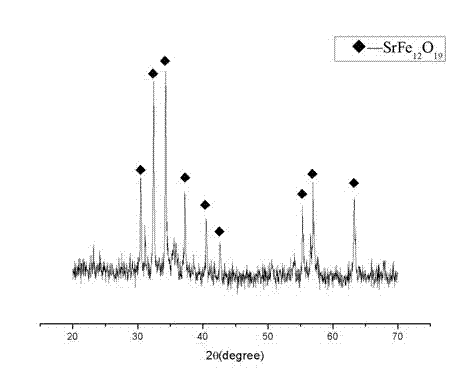

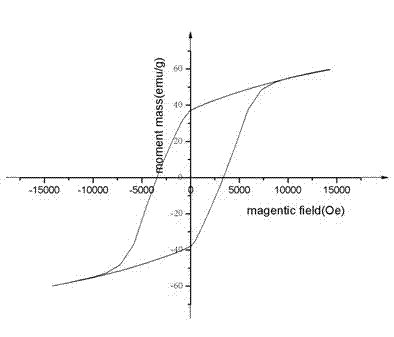

Image

Examples

Embodiment 1

[0020] A permanent magnet strontium ferrite powder and a preparation method thereof. Iron scale and analytically pure strontium carbonate are used as raw materials, wherein the molar ratio of analytically pure strontium carbonate to iron oxide is 1: (5.5~5.75), plus 0.1~0.5wt% polyethylene glycol of the raw material and 90~ 110wt% water to form a mixture; then according to the mass ratio of steel balls and raw materials (7.5-10): 1, the mixture is wet-milled in a steel ball mill tank until the particle size is 0.7-0.9 μm; Then the ball-milled slurry is dried, placed in a ceramic container and kept in a rotary kiln at 1050-1100°C for 120-240 minutes, and cooled naturally with the kiln to obtain permanent magnet strontium ferrite powder.

Embodiment 2

[0022] A permanent magnet strontium ferrite powder and a preparation method thereof. Iron scale and chemically pure strontium carbonate are used as raw materials, wherein the molar ratio of chemically pure strontium carbonate to iron oxide is 1: (5.5~5.75), plus 0.1~0.5wt% sorbitol of the raw material and 90~110wt of the raw material % water to form a mixture; then according to the mass ratio of steel balls and raw materials (7.5~10): 1, wet grind the mixture in a steel ball mill until the particle size is 0.7~0.9μm; then The ball-milled slurry is dried, placed in a ceramic container and kept in a rotary kiln at 1100-1150°C for 120-240 minutes, and cooled naturally with the kiln to obtain permanent magnet strontium ferrite powder.

Embodiment 3

[0024] A permanent magnet strontium ferrite powder and a preparation method thereof. Iron scale and industrial strontium carbonate are used as raw materials, wherein the molar ratio of industrial strontium carbonate to iron oxide is 1: (5.5~5.75), plus 0.1~0.5wt% calcium gluconate of the raw material and 90~110wt% of the raw material water to form a mixture; then according to the mass ratio of steel balls and raw materials (7.5-10): 1, wet-grind the mixture in a steel ball mill until the particle size is 0.7-0.9 μm; then The slurry after ball milling is dried, placed in a ceramic container and kept in a rotary kiln at 1150-1200°C for 120-240 minutes, and cooled naturally with the kiln to obtain permanent magnet strontium ferrite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap