Super-black and high-gross polycarbonate composite material and preparation method

A technology of polycarbonate and composite materials, which is applied in the field of ultra-black bright high-gloss polycarbonate composite materials and its preparation, and can solve problems such as pitting, matt, dispersion of fillers and carbon black powder, and processing difficulties , to achieve the effect of simple process, good mechanical properties and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

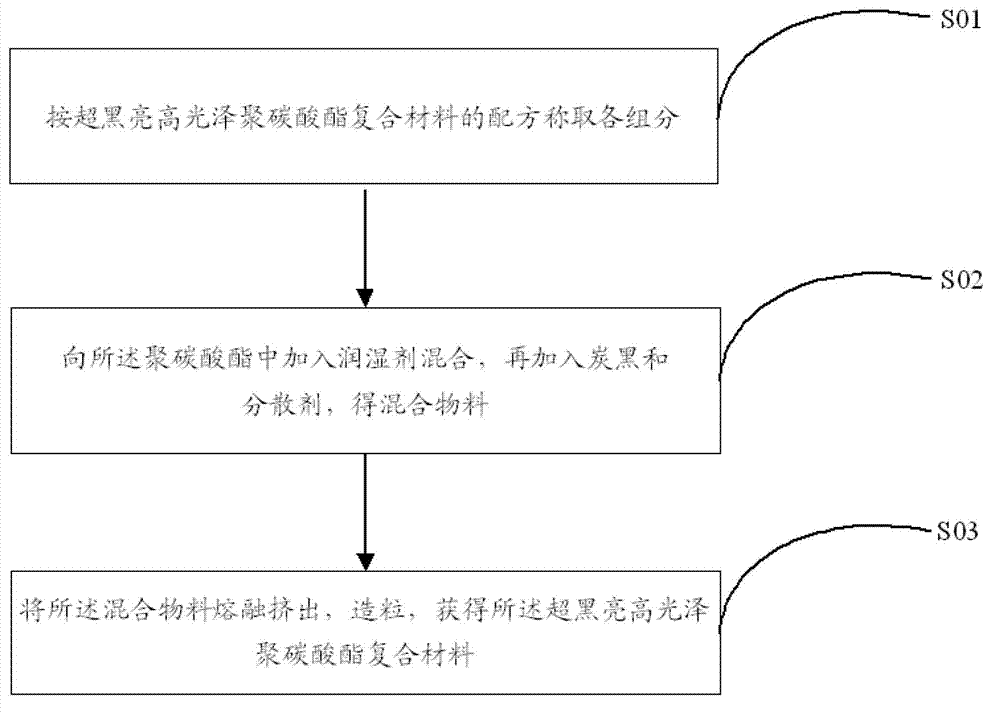

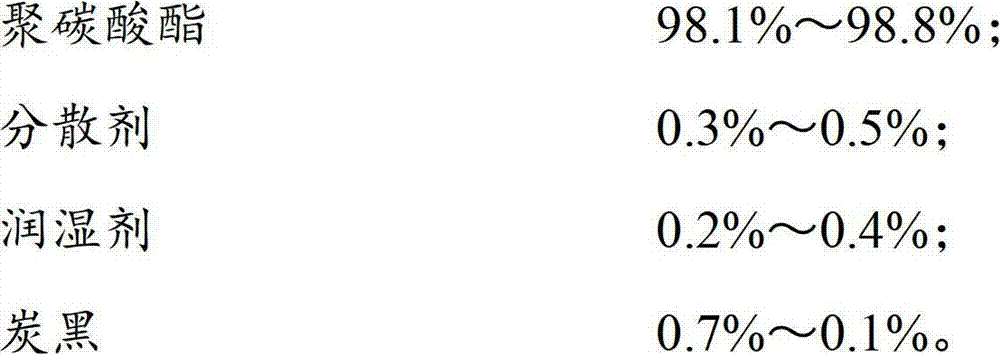

[0023] see figure 1 , showing a method for preparing an ultra-black and high-gloss polycarbonate composite material according to an embodiment of the present invention, which includes the following steps:

[0024] S01: Weigh each component according to the formula of the above-mentioned ultra-black bright high-gloss polycarbonate composite material;

[0025] S02: adding a wetting agent to the polycarbonate for mixing, and then adding carbon black and a dispersant to obtain a mixed material;

[0026] S03: Melt-extrude the mixed material and pelletize to obtain the ultra-black bright high-gloss polycarbonate composite material.

[0027] Specifically, in step S01, all materials are weighed accurately, accurate to 0.001 kilogram. The preferred content and type of each component in the high-ultra-black and high-gloss polycarbonate composite material formulation are as above, and will not be repeated here to save space.

[0028] Step S02 is as follows: put the polycarbonate in a ...

Embodiment 1

[0033] Components and weight percentages thereof of the ultra-black bright high-gloss polycarbonate composite material of the present embodiment are:

[0034]

[0035] Weigh all materials accurately to the nearest 0.001 kg. Dry the polycarbonate in a blast dryer at 110°C for 3 hours, then add a wetting agent, mix at a medium speed for 5 minutes, add carbon black and a dispersant, and mix at a high speed for 10 minutes until the mixture is uniform . Put the mixed material into the feeding hopper of the twin-screw extruder, melt and extrude, and granulate; among them, the process parameters are: the temperature of the first zone is 160°C, the temperature of the second zone is 180°C, the temperature of the third zone is 240°C, and the temperature of the fourth zone is 240°C. Zone temperature 240°C, zone 5 temperature 230°C, zone 6 temperature 230°C, zone 7 temperature 230°C, zone 8 temperature 230°C, die head temperature 250°C, material residence time 2min, pressure 10Mpa, sc...

Embodiment 2

[0037] Components and weight percentages thereof of the ultra-black bright high-gloss polycarbonate composite material of the present embodiment are:

[0038]

[0039] Weigh all materials accurately to the nearest 0.001 kg. Dry the polycarbonate in a blast dryer at 130°C for 5 hours, then add a wetting agent, mix at a medium speed for 8 minutes, add carbon black and a dispersant, and mix at a high speed for 15 minutes until the mixture is uniform . Put the mixed material into the feeding hopper of the twin-screw extruder, melt and extrude, and granulate; among them, the process parameters are: the temperature of the first zone is 180°C, the temperature of the second zone is 200°C, the temperature of the third zone is 260°C, and the temperature of the fourth zone is 260°C. Zone temperature 260°C, zone 5 temperature 250°C, zone 6 temperature 250°C, zone 7 temperature 250°C, zone 8 temperature 240°C, die head temperature 260°C, material residence time 3min, pressure 20Mpa, sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com