Well blowout processing device of geothermal system

A treatment device and geothermal technology, which is applied to isolation devices, wellbore/well components, earth-moving drilling, etc., can solve problems such as unsatisfactory treatment effect, and achieve the effects of low cost, good effect and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

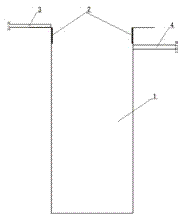

Embodiment 1

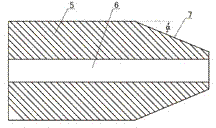

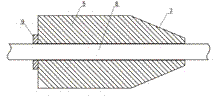

[0036] The specific processing method of the water-absorbing plug 5 is as follows:

[0037] 1. Choose a section of high-quality green gang round wood;

[0038] 2. Machining the round wood into a concentric cylinder with a height of 0.6~0.8m and a diameter 10cm larger than the diameter of the surface casing 2;

[0039] 3. One end of the log is processed into a cone with a trapezoidal longitudinal section and a height of 30 cm;

[0040] 4. Divide the cork into two evenly along the longitudinal centerline of the log, and cut it with a wood saw;

[0041] 5. Dig the volume corresponding to the drill pipe 8 along the axial centerline of the log to form a through hole 6 (the two halves are not shown in the figure), and cut out 1 / 2 of each piece to completely fit the drill pipe;

[0042] 6. Surface casing 2 adopts stainless steel casing.

[0043] Then operate according to the above operation steps until the drilling fluid reaches a balanced state, take out the drill pipe 8, close the main wellhea...

Embodiment 2

[0045] It is carried out according to Example 1, but the material of the water-absorbing plug 5 is iron wood, and the rest is the same as in Example 1.

Embodiment 3

[0047] It is carried out according to Example 1, but the material of the water-absorbing plug 5 is oak, and the rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com