Tunnel collapse life saving machine

A life-saving machine and tunnel technology, applied in the field of rescue equipment and tunnel collapse life-saving machines, can solve problems such as reports of tunnel collapse life-saving machines that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

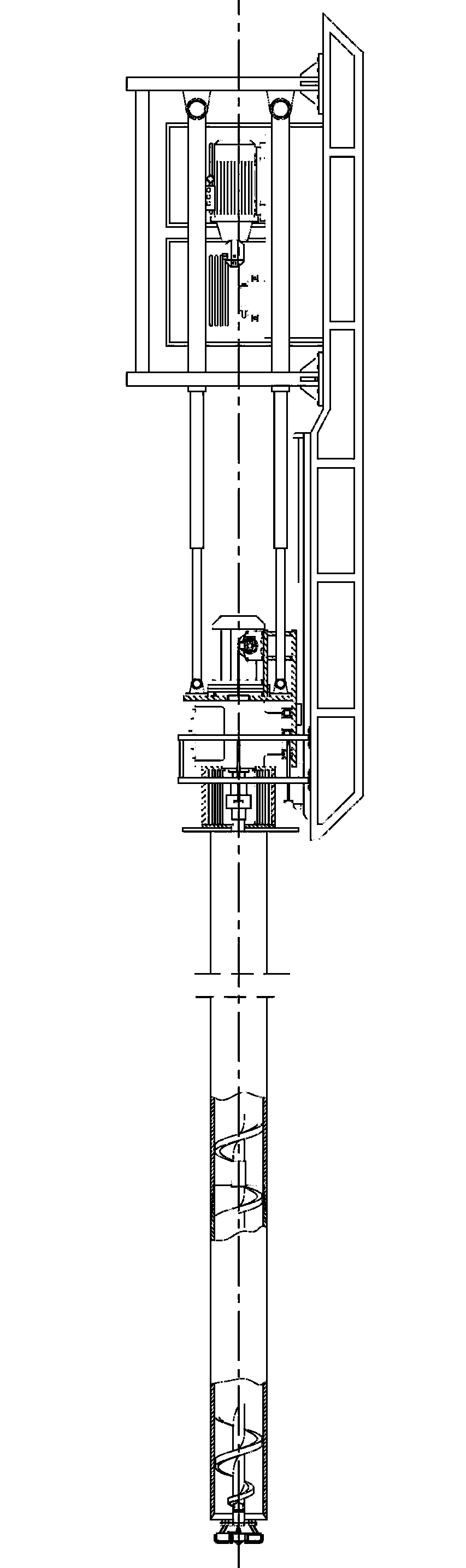

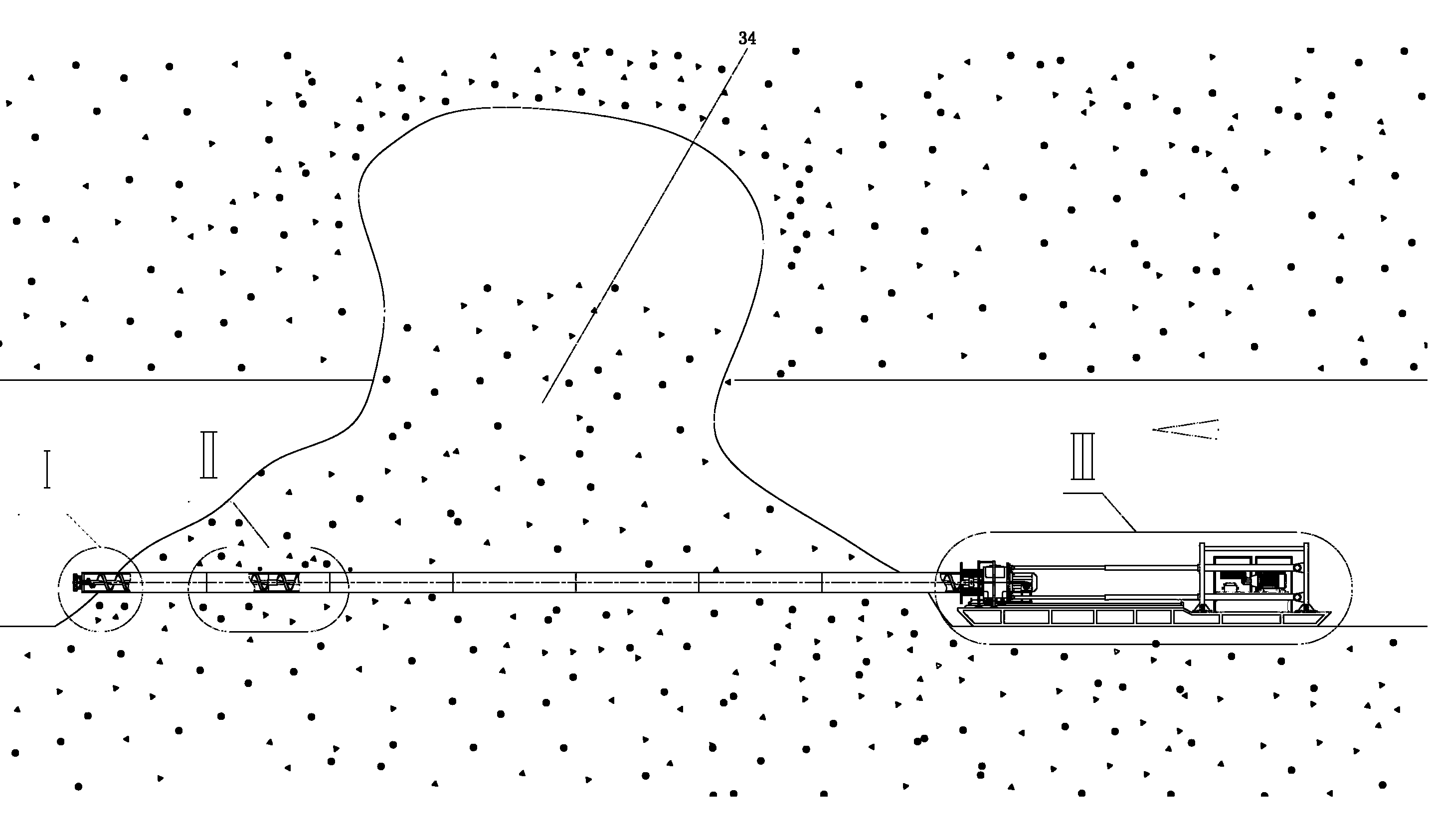

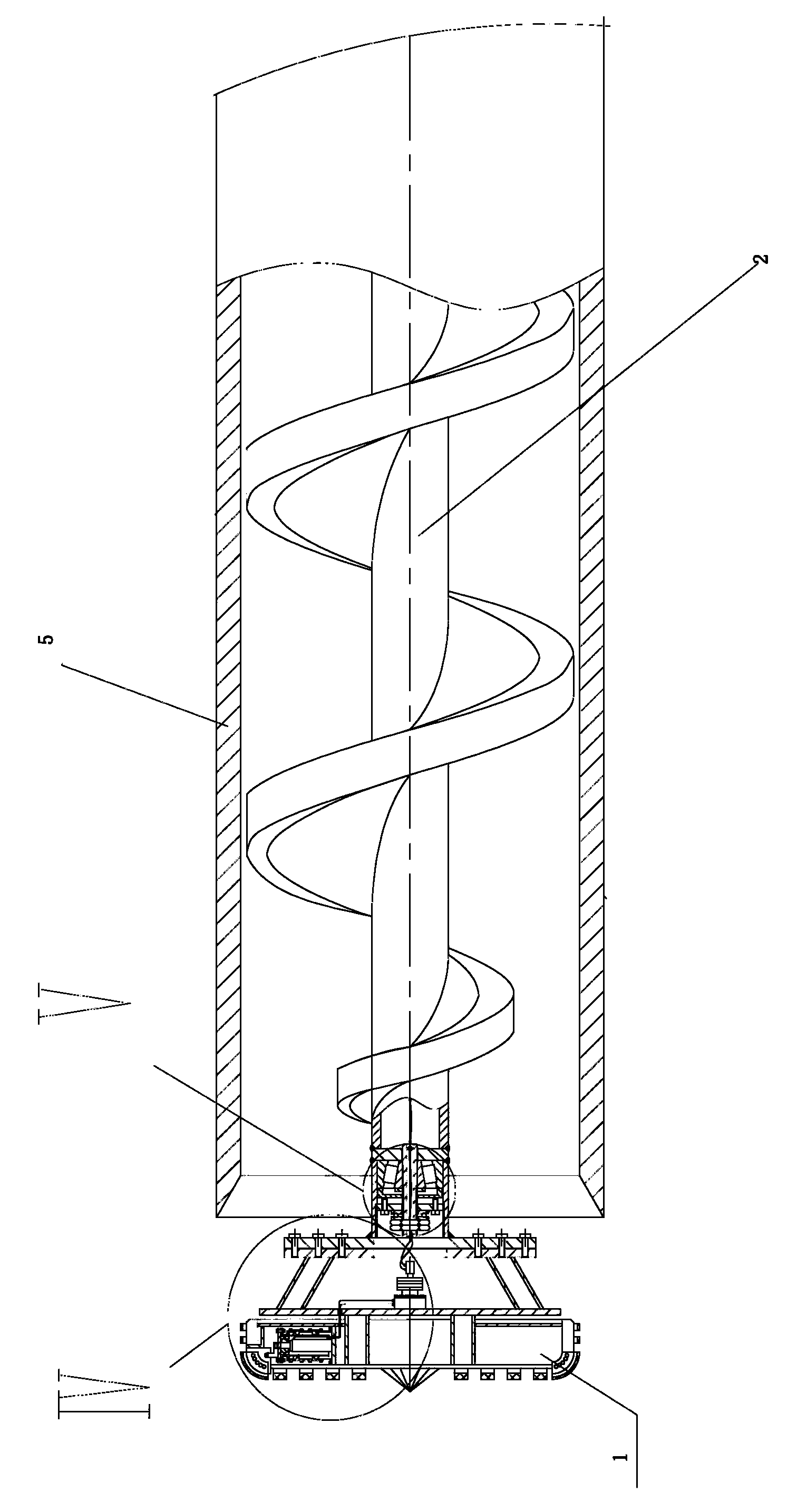

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 as shown, figure 2 The middle arrow shows the tunneling direction. The serial numbers in the figure are as follows: 1. Cutting head with variable diameter function, 2. Screw conveying shaft, 3. Drive motor, 4. Hollow shaft reducer, 5. Life preserver, 6. Propelling cylinder, 7. Auxiliary cylinder, 8. Sliding base, 9, sliding shoe, 10, guide rail, 11, electric winch, 12, angular contact bearing, 13, thrust bearing, 14, oil tank, 15, pumping station motor, 16, hydraulic pump, 17, valve group, 18, Power distribution cabinet, 19, control cabinet, 20, chassis, 21, bed, 22, bed skids, 23, head cover, 24, coupling, 25, squirrel cage thrust frame, 26, end of life preserver Transition joint, 27, side scraper, 28, steel wire rope, 29, hinge, 30, mandrel, 31, bearing seat, 32, screw conveyor shaft extension joint, 33, safety belt, ...

Embodiment 2

[0058] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 shown. The lifesaving machine structure and lifesaving process of this embodiment are basically the same as those of Embodiment 1, but also have the following differences.

[0059] The driving motor in the rotary drive device of the screw conveying shaft is changed to a hydraulic motor, and the electric winch is changed to a hydraulic winch.

[0060] For the convenience of transportation, the chassis 20 is changed from integral type to split type. It is composed of 2 boxes, the split plane is located in the middle, and each of the two boxes is provided with a connection plate, which is connected with high-strength bolts. The split type chassis is convenient. Transportation under construction.

[0061] After forming a transparent space in the life-saving cylinder 5, use a commerci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com