Biomass furnace with liftable furnace grate

A technology for biomass stoves and grates, which is applied in household stoves/stoves, sustainable buildings, and climate sustainability. The effect of staying, reducing heat dissipation, and stabilizing the lifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

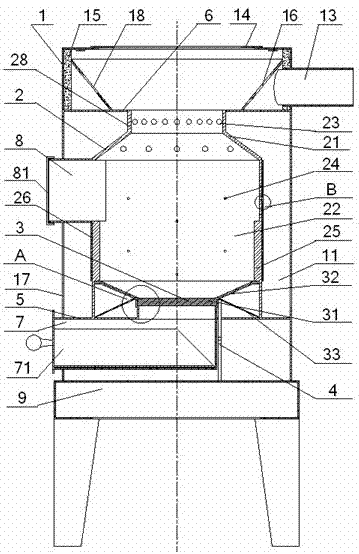

[0058] The biomass furnace with a liftable grate of the present invention mainly uses stainless steel and carbon steel as materials, and is manufactured by stamping or welding.

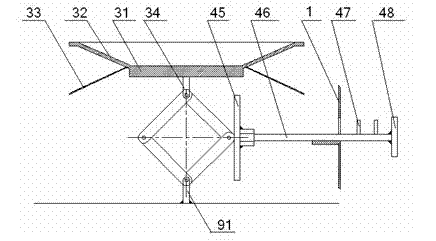

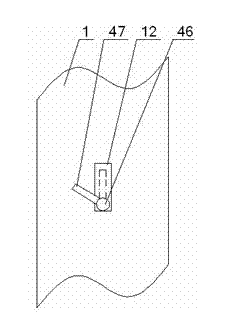

[0059] In the present invention, the top of the furnace seat 9 is provided with a furnace outer chamber 1, and the top of the furnace outer chamber 1 is provided with a pan ring 14, and the inside of the furnace outer chamber 1 is provided with a coaxial furnace inner chamber 2, and the furnace inner chamber 2 includes The conical burner 21 is connected with the cylindrical combustion chamber 22, and the fire guide wall 28 at the top of the conical burner 21 is connected with the side wall of the furnace outer chamber 1 through the upper cover plate 6, and the upper cover plate is near the furnace outer chamber 1 side wall 6 is provided with a flue 13; a fire arresting ring 16 is arranged between the upper cover plate 6 and the pot ring 14, and the outer edge of the top of the fire arresting ring 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com