Device and method for measuring sudden/large-dynamic range partial discharge ultrasonic signal

A large dynamic range, ultrasonic signal technology, applied in the direction of testing dielectric strength, etc., can solve the problems of missing small signal sampling, loss of measurement information, and difficulty in setting the trigger level correctly, so as to suppress false triggering and improve positioning The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

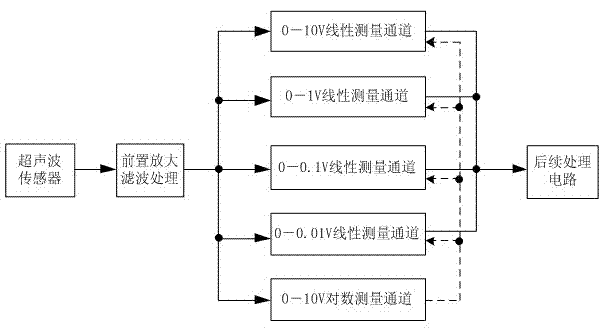

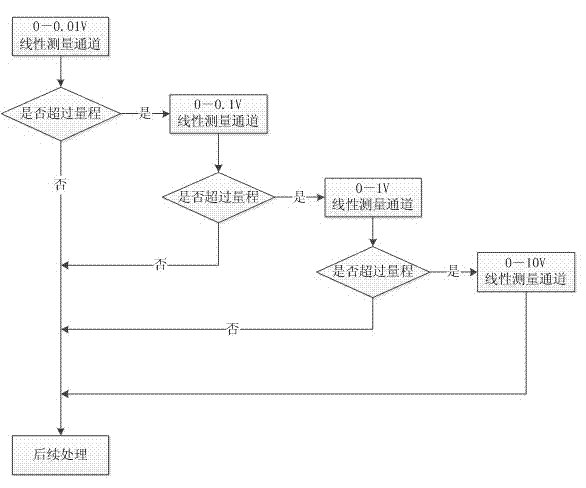

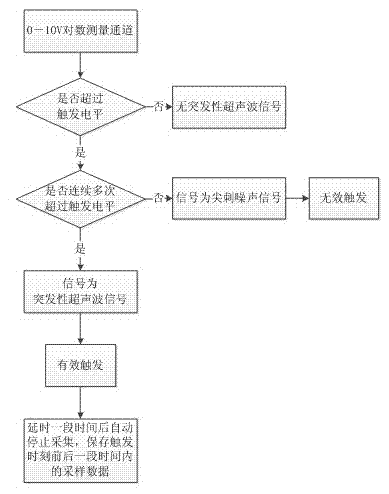

[0024] like figure 1 As shown, the embodiment of the precise measurement device for sudden / large dynamic range ultrasonic signals of the present invention includes ultrasonic sensors, pre-amplification filter processing modules, measurement channels and follow-up processing circuits connected in sequence, and the measurement channels are 4 parallel There are linear measurement channels with different ranges, the ranges are 0-0.01V, 0-0.1V, 0-1V and 0-10V; the measurement channels include A / D analog-to-digital converters, and the resolution of A / D analog-to-digital converters The rate is 16Bit; the measurement channel is also connected in parallel with a logarithmic measurement channel that selects the sampling data with the highest quantization accuracy as the final result from the linear measurement channels of different ranges, and the logarithmic measurement channel also includes A / D analog-to-digital converters.

[0025] The method for measuring the burst / large dynamic ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com