Motor rotor and motor with motor rotor

An electric motor and rotor technology, applied in the field of electric motors, can solve the problems of inability to meet the urgent requirements of electric motor efficiency, limitations, high price, etc., and achieve the effects of improving electric motor efficiency, reducing the amount of rare earth, and increasing reluctance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

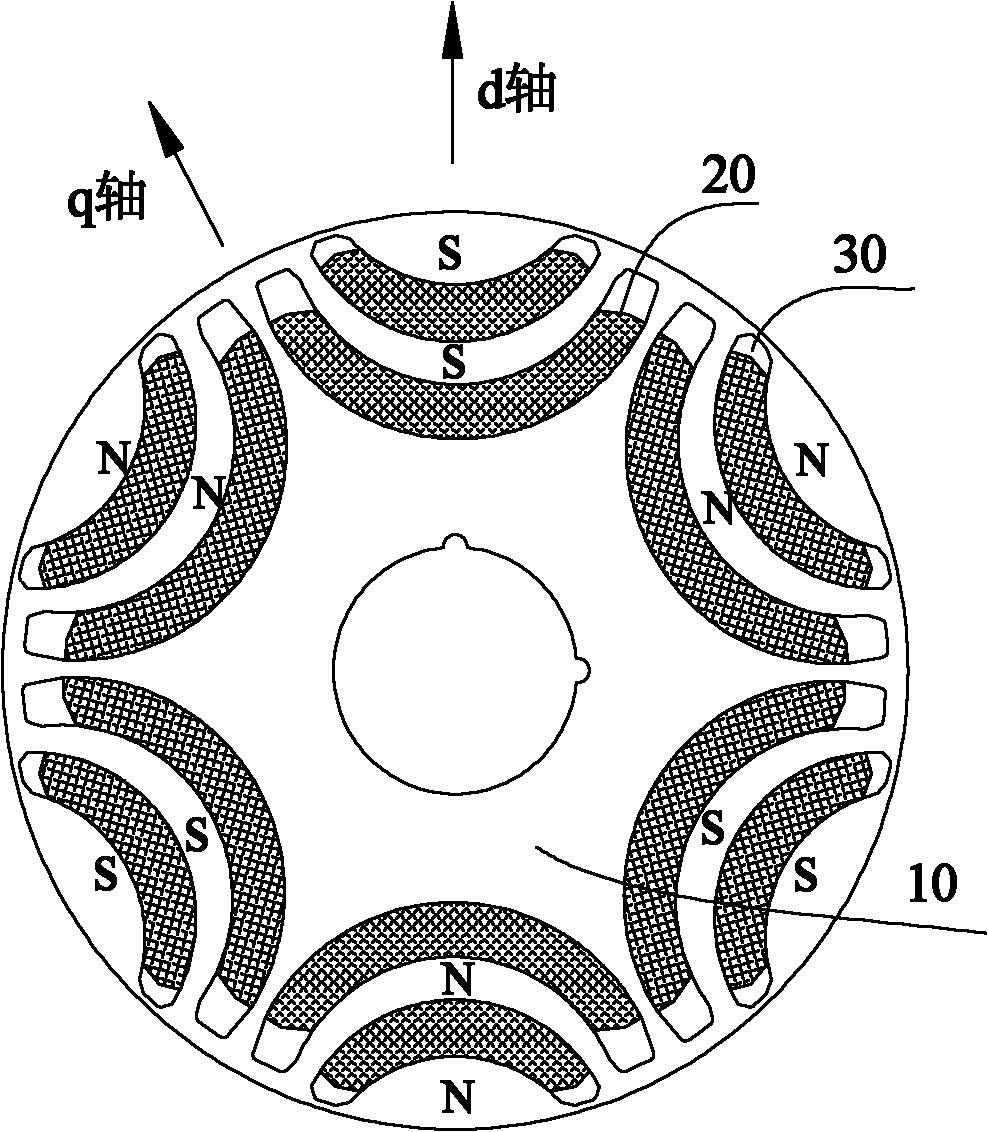

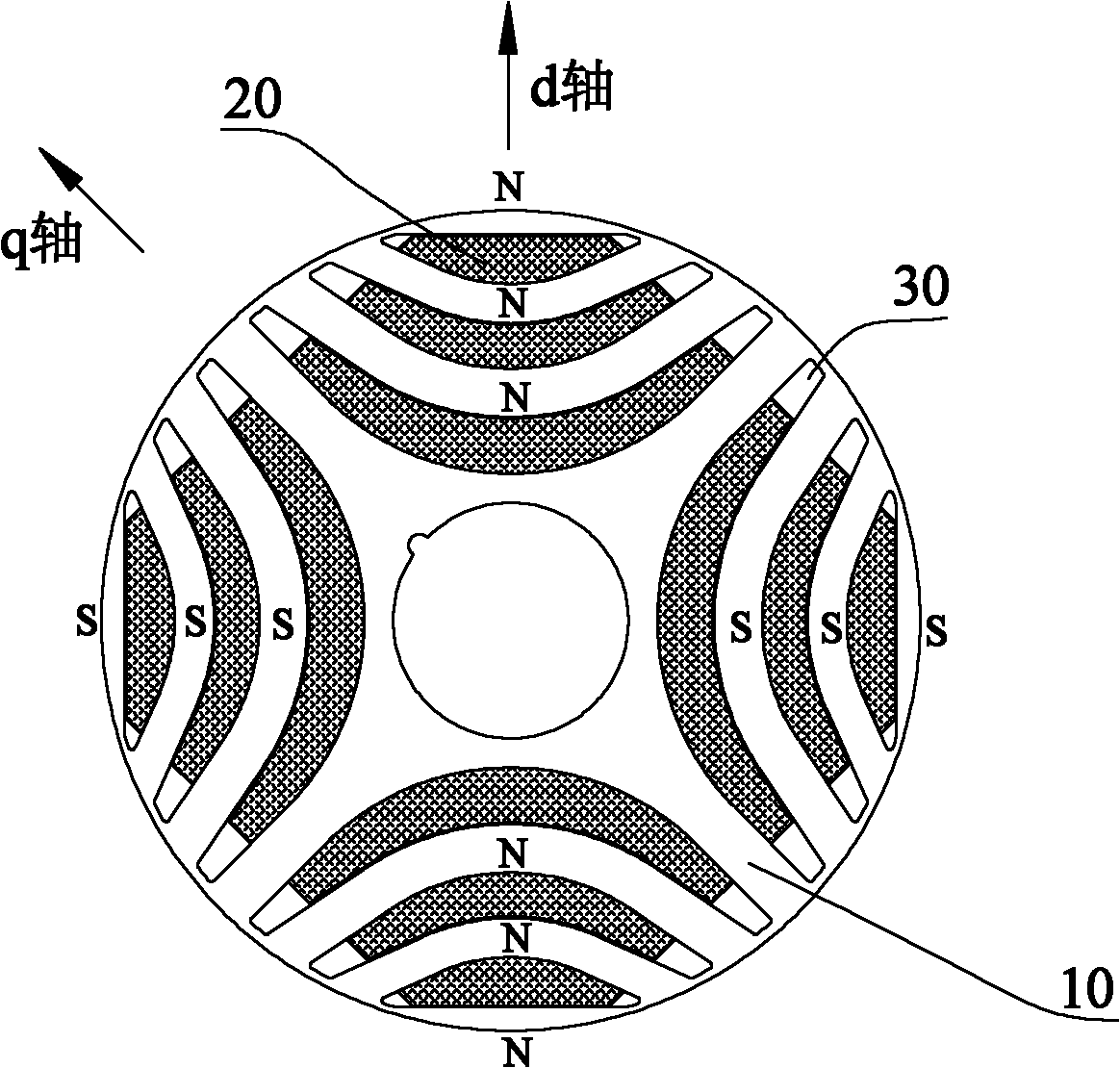

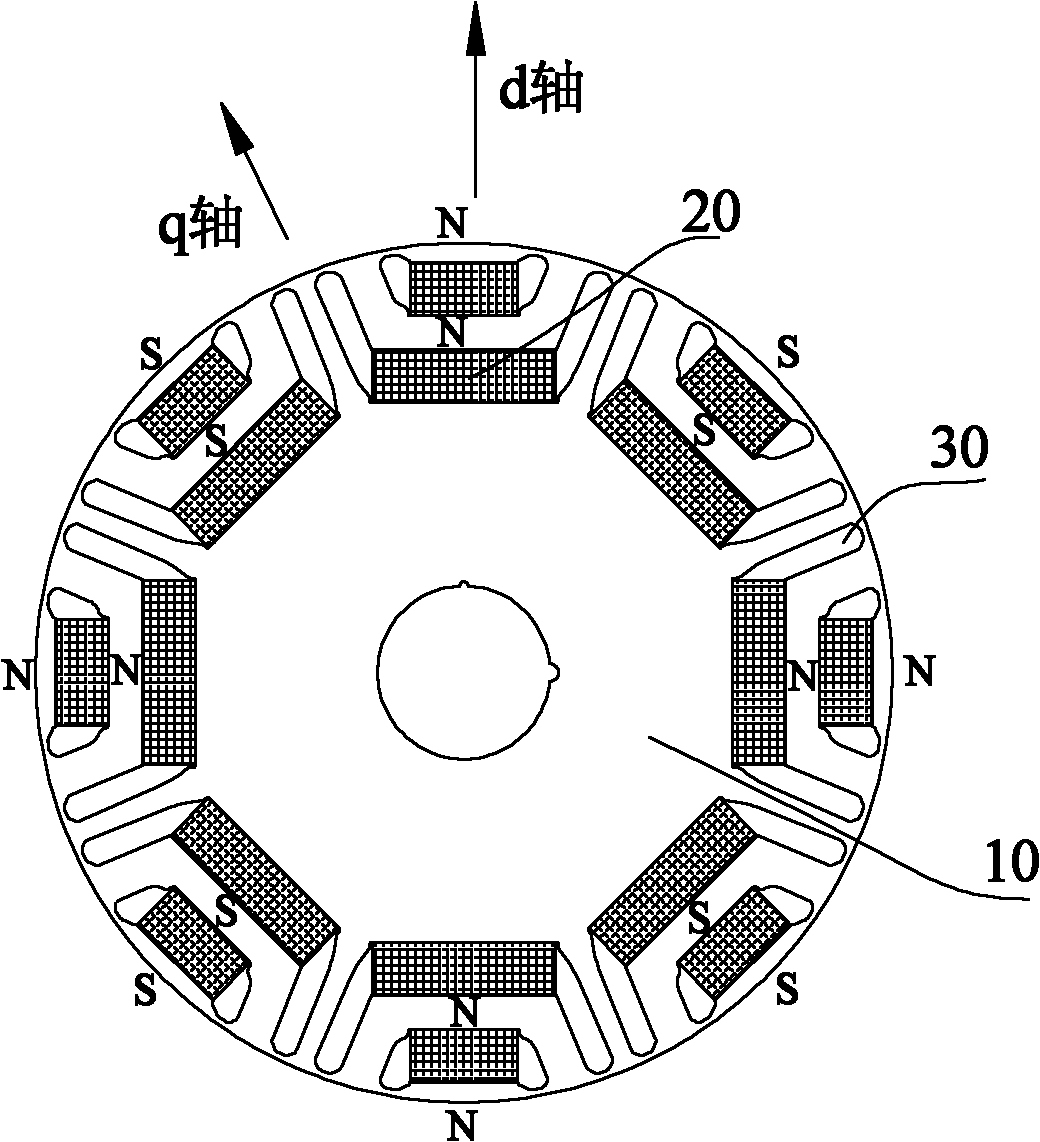

[0033] Such as figure 1 As shown in the first embodiment of the engine rotor according to the present invention, the motor rotor includes an iron core 10 and a permanent magnet 20 disposed inside the iron core 10, and the iron core 10 is provided with multiple sets of mounting grooves 30 along the circumferential direction of the iron core 10, Each group of mounting grooves 30 includes two or more than two mounting grooves 30 intermittently arranged in the radial direction of the iron core 10; there are multiple groups of permanent magnets 20, and each permanent magnet 20 in each group of permanent magnets 20 is embedded in each group correspondingly. In each of the installation grooves 30 of the installation grooves 30 .

[0034] figure 1 The iron core 10 of the engine rotor in the engine is made of laminated silicon steel plates and has a certain stack height. With the axis of the iron core 10 as the center of the circle, six sets of mounting grooves 30 are evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com