Process for assisting in foaming of cross-linked polyolefin as well as ultrasonic treatment device for process

A technology of cross-linking polyolefin and processing device, which is applied in the field of polymer foaming technology, can solve the problems of excessive pore size, different pore size, rupture, etc., and achieve the effect of improving quality, excellent performance and fine bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

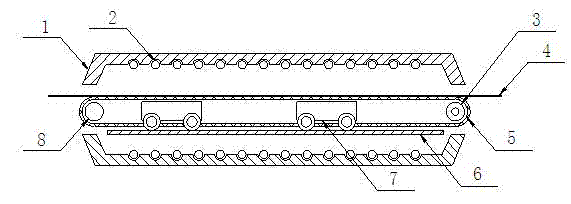

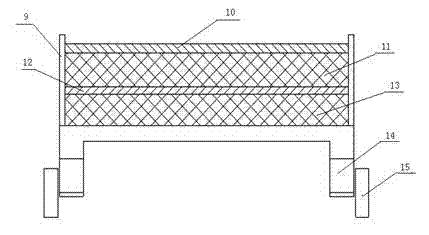

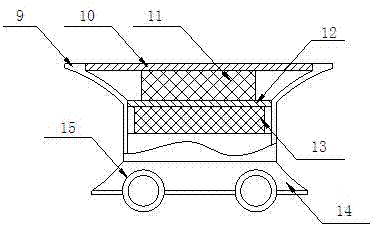

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment is a process for assisting cross-linked polyolefin foaming and its ultrasonic treatment device. The polyolefin foam material is subjected to ultrasonic treatment, and multiple sets of ultrasonic treatment devices 7 can be installed in the foaming furnace according to the ultrasonic treatment effect of the final product. Described ultrasonic processing device 7 comprises base 14, body 9, ultrasonic generator 13, ultrasonic transducer 11 and control and power supply part; Described base 14 two ends have two pulleys 15 respectively, on both sides of foaming furnace A guide rail 6 is respectively arranged on the inner wall, and the pulleys 15 at the two ends of the base 14 are installed on the guide rail 6 and can move back and forth along the guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com