Manufacturing process for weaving machinery of UD (uni-directional) weftless bulletproof fabric

A technology of weaving machinery and bulletproof cloth, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of limited processing speed, low processing efficiency, cumbersome operation, etc., to improve product performance, increase production efficiency, and operate Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

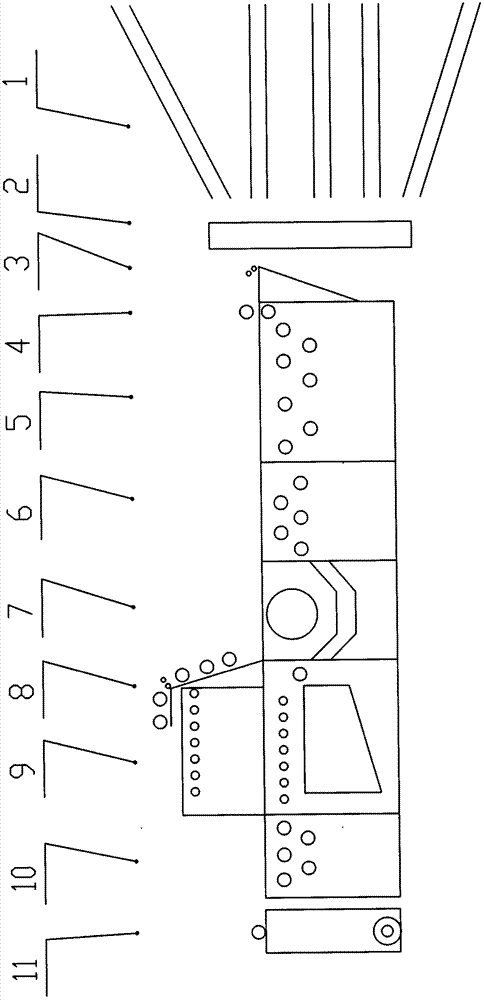

[0016] Attached below figure 1 , 2, 3 the present invention is described in further detail:

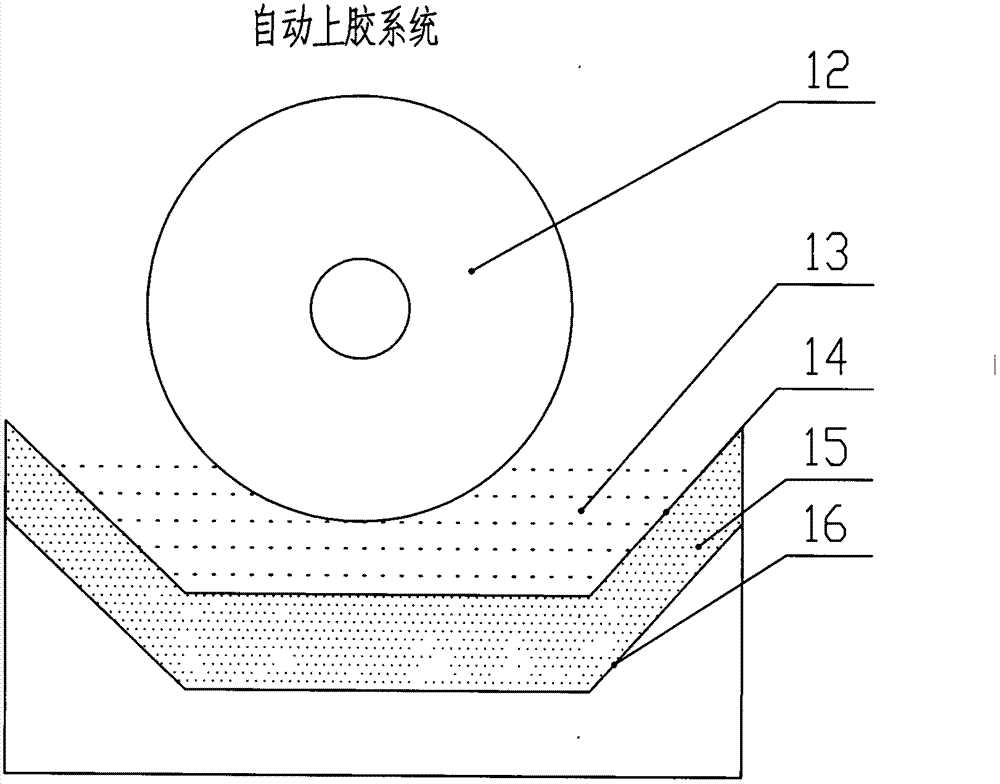

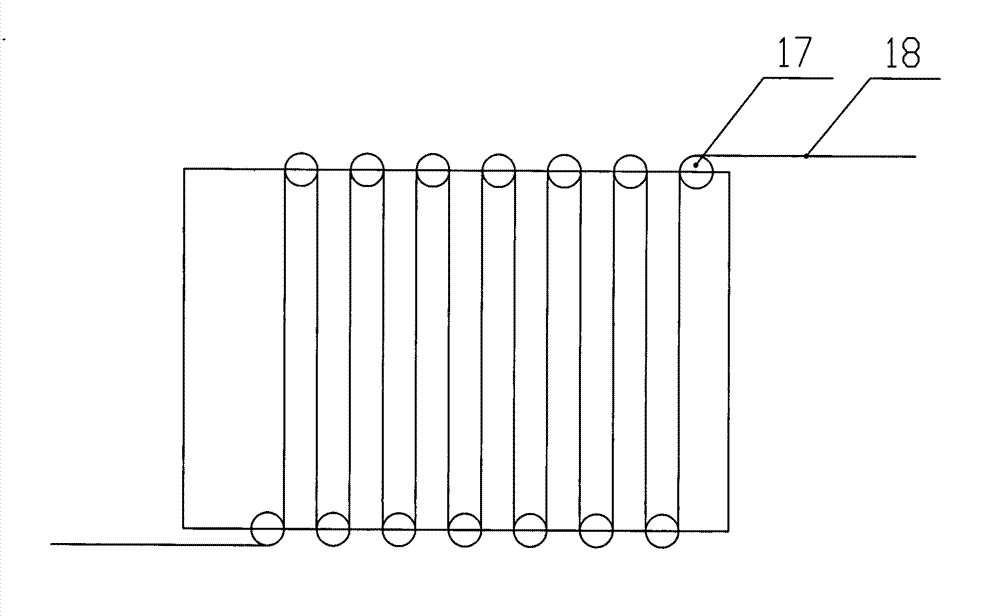

[0017] The invention provides a UD unidirectional non-weft bulletproof fabric weaving machine, which consists of a creel area 1, an evenly arranged area 2, a tension area 3, a glue compression area 4, a seven-roll tension area 5, a five-roll stretch area 6, and gluing System 7, film stretching system 8, drying room area 9, traction area 10, torque area 11. Start the machine, N yarn drums are used to unwind at the same time, and the unwinding is uniform. The seven-roller tension zone 5 provides the tension required for unwinding. The five-roller spreading zone 6 spreads the fiber yarns flat through the action of friction. The glue system 7, the rubber roller 12 and the glue tank 14 keep a certain position, the volume of the glue 13 is kept constant, and the hot water 15 in the hot water tank 16 is kept at a certain temperature, so as to maintain the viscosity of the glue 13, and sprea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com