Suction-exhaust drying recovering device for train toilet

A recovery device and drying technology, applied in the field of sanitary equipment, can solve problems such as increased maintenance workload, corrosion of rails and their parts, and hazards to line vehicles, etc., and achieve the goal of reducing railway operating costs, simple and reasonable structure, and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

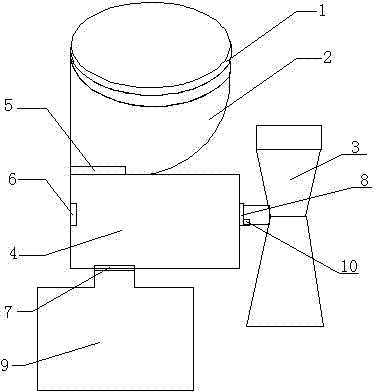

[0015] Suction and drainage drying recovery device for train toilets, including urinal 2, toilet lid 1 arranged on the urinal, suction and drainage drying box 4 set at the bottom of the urinal, garbage bag 9 at the bottom of the suction and drainage drying box, Venturi tube 3, the other side of the suction and exhaust drying box is provided with an exhaust port 6, and the Venturi tube is arranged on the outside of the train. A filter screen and a humidity sensor are arranged at the connection. The connection between the urinal and the suction and drainage drying box is provided with a suction and discharge port 5, and the connection between the bottom of the suction and drainage drying box and the garbage bag is provided with a sewage discharge port 7. Solenoid valves are installed at the exhaust port, suction and discharge port, sewage discharge port and drying port.

[0016] The inner wall of the urinal is provided with a photocatalyst coating, and the inner surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com