Installation method of bow transverse thrust unit

An installation method and bow technology, applied in ship components, ship construction, transportation and packaging, etc., can solve the problems of insufficient side thrust, high installation requirements, and large equipment loss, etc., to achieve strong output power, broad market space, The effect of high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

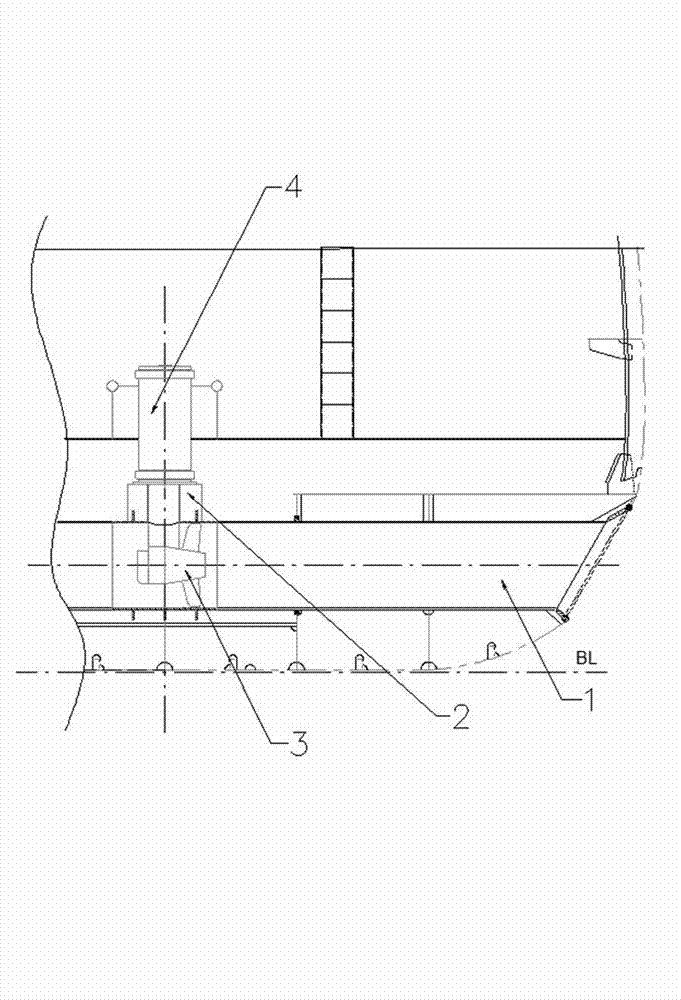

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] As shown in the figure, take a 5,000-ton container ship as an example, the main technical parameters:

[0020] 1. Model: STT-110LK 2. Propeller 3 Diameter: 800mm

[0021] 3. Input speed: 1470r / min

[0022] 4. Speed ratio: i=1.86:1

[0023] 5. Propeller 3 blade material: G-Cu-Zu35A11+5%Ni

[0024] 6. Standard thrust: about 25KN

[0025] 7. Length of barrel 1: 1000mm

[0026] 8. Thickness of barrel 1: 15mm

[0027] 9. Motor 4: Power: 180KW

[0028] The installation method of the bow thruster of the present invention comprises the following steps:

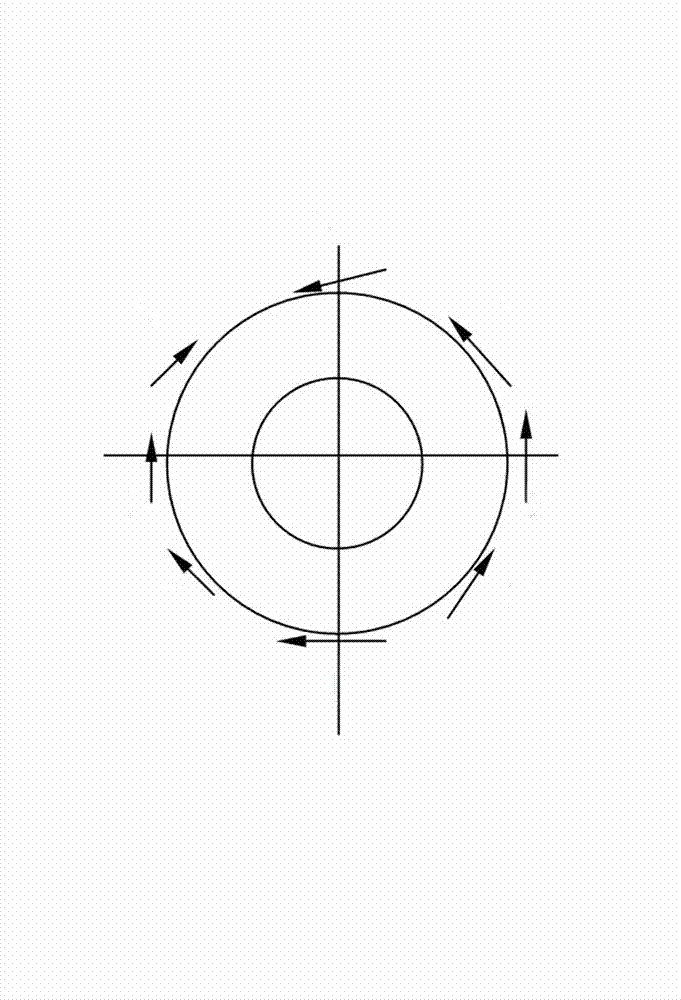

[0029] A. The side thrust cylinder 1 is pre-installed on the starboard and starboard sides of the bottom of the hull, check and correct the roundness of the cylinder 1, and mark the centerline of the cylinder 1;

[0030] B. Measure the height from the centerline of cylinder 1 to the baseline BL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com