Delivery system allowing delivery boxes to be automatically recycled

A conveying system and automatic circulation technology, applied in the field of conveying systems, can solve the problems of failing to meet safety inspections, covering a large area, not having a transport box emptying judgment system and a suspicious item tracking alarm system, etc., to achieve safety inspections. , The system structure is compact, the effect of solving the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

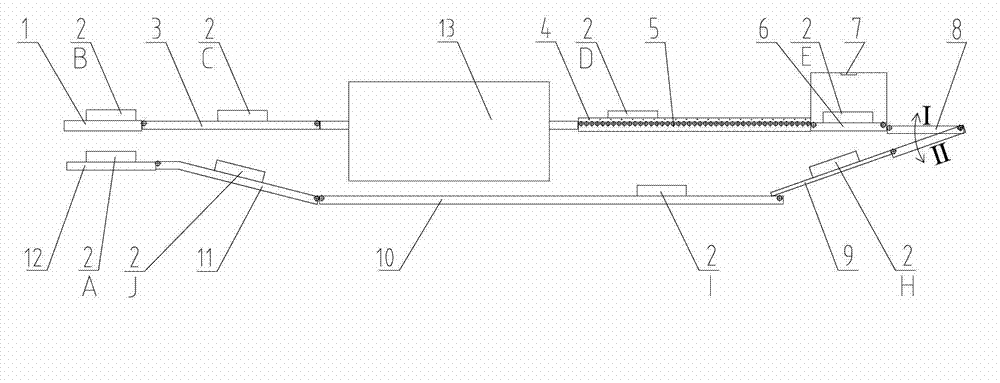

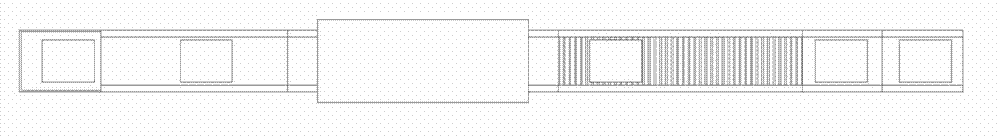

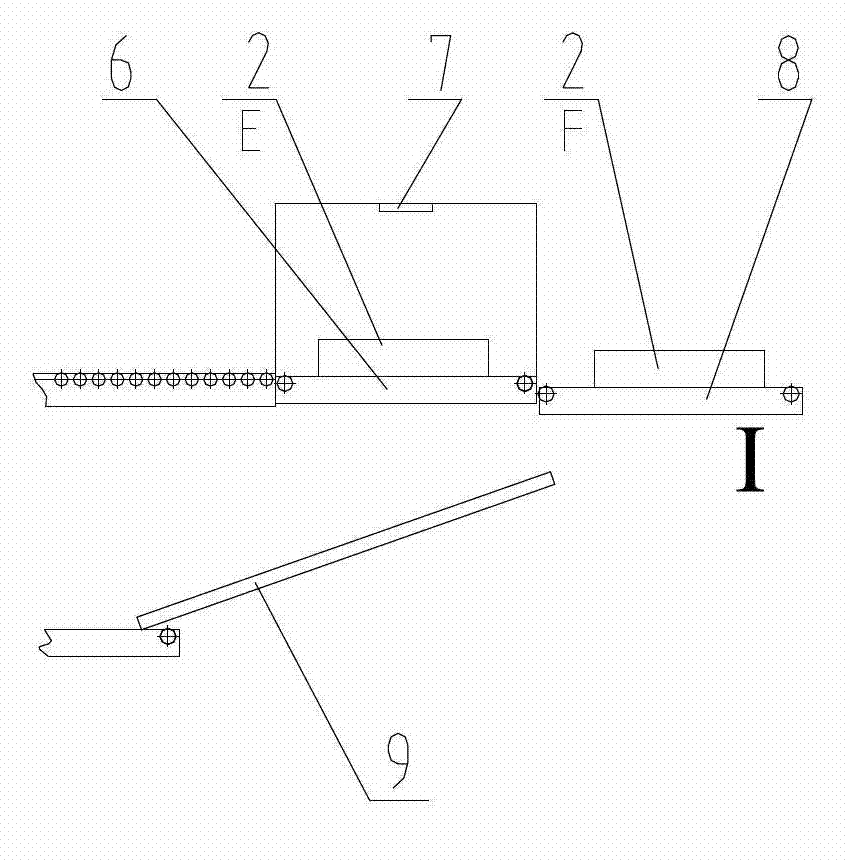

[0017] Hereinafter, the present invention will be described in detail in combination with embodiments according to FIG. 1 to FIG. 5 .

[0018] The embodiment of the present invention is a conveying system for automatic recycling of transport boxes used in conjunction with safety inspection equipment, which includes: safety inspection equipment 13, a smooth table 1 for customers to place items, transport boxes 2, belt conveyors 3, storage Putting and conveying device 5, transport box emptying judgment system 7, suspicious article tracking and alarm system 4, diverter 8, stainless steel rolling bed or slide plate 9, belt flat conveyor 10, belt inclined conveyor 11 and backup platform 12.

[0019] The smooth table 1 and the belt conveyor 3 are located at the entrance of the safety inspection equipment 13, the accumulation conveying device 5 is connected to the exit of the safety inspection equipment 13, and the suspicious article tracking alarm system 4 is installed on the side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com