Technological method for co-producing industrial-grade carbon dioxide and food-grade carbon dioxide through heat pump rectification

A carbon dioxide and heat pump rectification technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problem of high energy consumption, achieve the effect of reducing energy consumption and adjusting production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

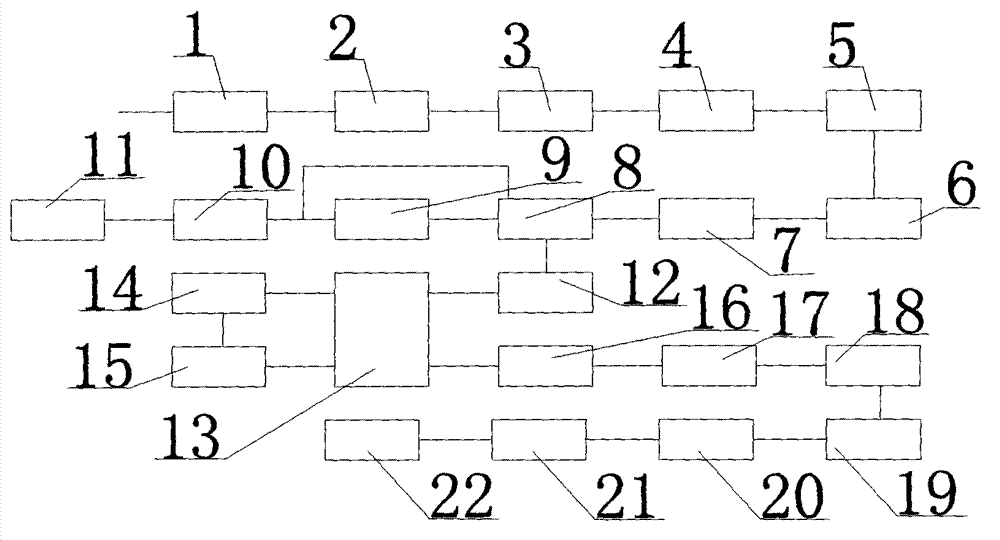

Image

Examples

Embodiment 1

[0030] This embodiment is a normal production condition. To produce 10 tons of industrial-grade carbon dioxide and 2.5 tons of food-grade carbon dioxide requires a total of 10,000 cubic meters of raw gas.

[0031] 1. The raw material gas of 10,000 cubic meters is precooled and dehydrated in the first precooling and dehydration section and then enters the four-stage compression section. The pressure of the raw material gas after the four-stage compression section is 2.5 MPa;

[0032] 2. The raw material gas compressed in step 1 is sequentially passed through a rough desulfurization section, a hydrolysis section and a fine desulfurization section, so that the sulfur content in the raw material gas is reduced to 0.09ppm;

[0033] 3. Pass the raw material gas desulfurized in step 2 through the second pre-cooling and dehydration section and discharge the cooling water to lower the temperature of the raw material gas to 4°C;

[0034] 4. The raw material gas after the second pre-cool...

Embodiment 2

[0041] To produce 5 tons of industrial-grade carbon dioxide and 1.2 hours of food-grade carbon dioxide requires a total of 5,000 cubic meters of raw gas.

[0042] 1. The raw material gas of 5000 cubic meters is precooled and dehydrated in the first precooling and dehydration section and then enters the four-stage compression section. The pressure of the raw material gas after passing through the four-stage compression section is 3.0 MPa;

[0043] 2. The raw material gas compressed in step 1 is sequentially passed through a rough desulfurization section, a hydrolysis section and a fine desulfurization section, so that the sulfur content in the raw material gas is reduced to 0.05ppm;

[0044] 3. Pass the raw material gas desulfurized in step 2 through the second pre-cooling and dehydration section and discharge the cooling water to lower the temperature of the raw material gas to 5.5°C;

[0045] 4. The raw material gas after the second pre-cooling and dehydration section is passed...

Embodiment 3

[0052] To produce 3 tons of industrial-grade carbon dioxide, a total of 2,500 cubic meters of raw material gas is required.

[0053] 1. The raw material gas of 2500 cubic meters is precooled and dehydrated in the first precooling and dehydration section and then enters the four-stage compression section. The pressure of the raw material gas after the four-stage compression section is 3.5 MPa;

[0054] 2. The raw material gas compressed in step 1 is sequentially passed through a rough desulfurization section, a hydrolysis section and a fine desulfurization section, so that the sulfur content in the raw material gas is reduced to 0.01ppm;

[0055] 3. Pass the raw material gas desulfurized in step 2 through the second pre-cooling and dehydration section and discharge the cooling water to lower the temperature of the raw material gas to 7°C;

[0056] 4. Pass the raw material gas after the second pre-cooling and dehydration section through the drying section, so that the water cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com