Acid soil conditioner prepared by biomass power generation waste and preparation method of acid soil conditioner

A technology of biomass power generation and acidic soil, applied in the direction of application, fertilizer mixture, fertilization device, etc., can solve the problems of nutrient waste, damage to soil aggregate structure, soil quality degradation, etc., and achieve the effect of solving acidification problems and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

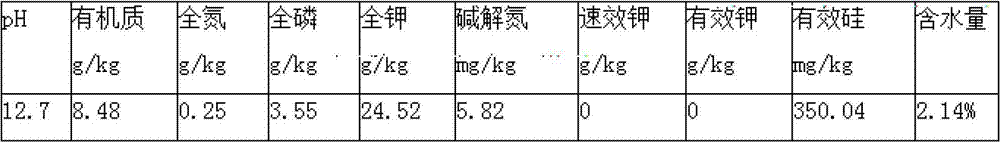

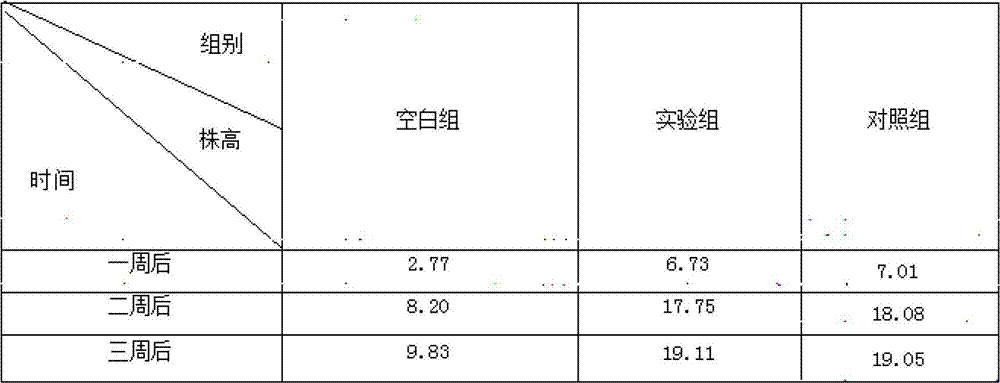

Embodiment 1

[0021] Biomass power generation waste and bio-black carbon are mixed at a weight ratio of 3:1, then added to red soil (20% of the weight of biomass power generation waste and bio-black carbon), and then 30% of the weight of biomass power generation waste and bio-black carbon is added. % water for granulation. The obtained soil conditioner has a pH of 9.02, a water content of 2.27%, and a bulk density of 2.49g / cm 3 , The maximum water absorption is 85.70%. Mixed with acidic soil at a ratio of 1:25 (by weight), the pH of the acidic soil increased from 4.49 to 5.99 after five days.

Embodiment 2

[0023] The difference from Example 1 is that biomass power generation waste: bio-black carbon = 2:1, red soil (25% of the weight of biomass power generation waste and bio-black carbon), and then add biomass power generation waste and bio-black carbon 20% by weight of water for granulation. The resulting amendment was mixed with acidic soil at a ratio of 1:25, and the pH of the acidic soil increased from 4.49 to 5.82 after five days.

Embodiment 3

[0025] The difference from Example 1 is that biomass power generation waste: bio-black carbon=3:2, red soil (22% of the weight of biomass power generation waste and bio-black carbon), and then add biomass power generation waste and bio-black carbon 25% by weight of water for granulation. Mixed with acidic soil at a ratio of 1:25, the pH of the acidic soil increased from 4.49 to 6.24 after five days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com