Excavation tunnel heat-insulation flow-dividing heat discharge cooling method

A technology of shunting row and roadway, which is applied in the direction of earth drilling, mine/tunnel ventilation, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

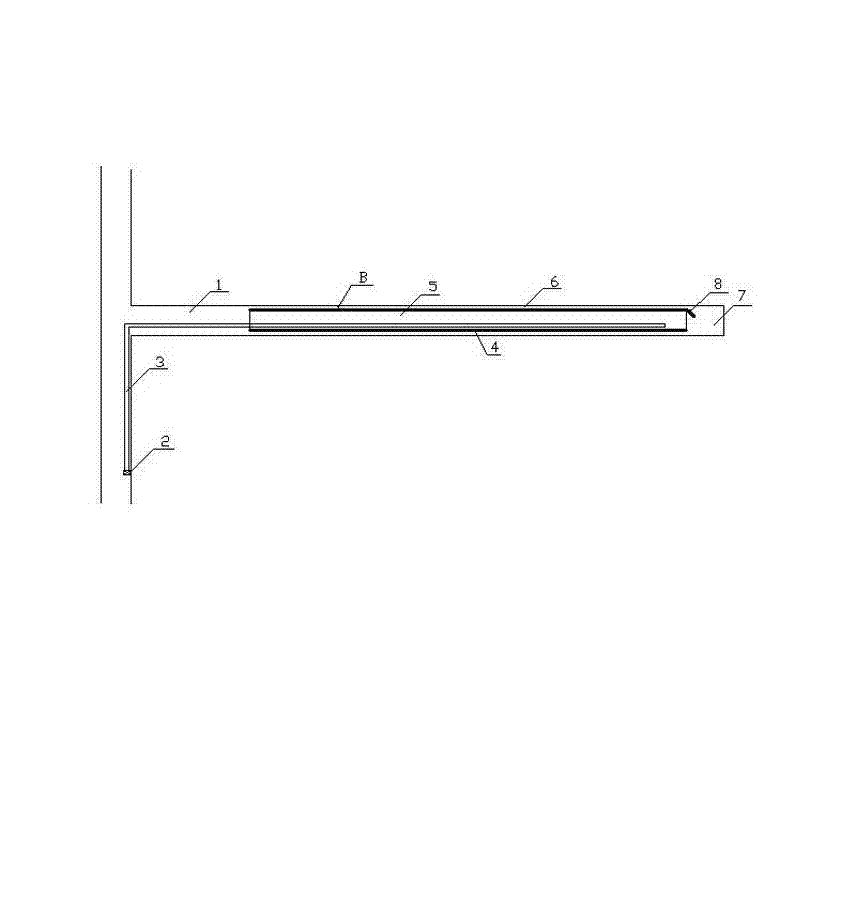

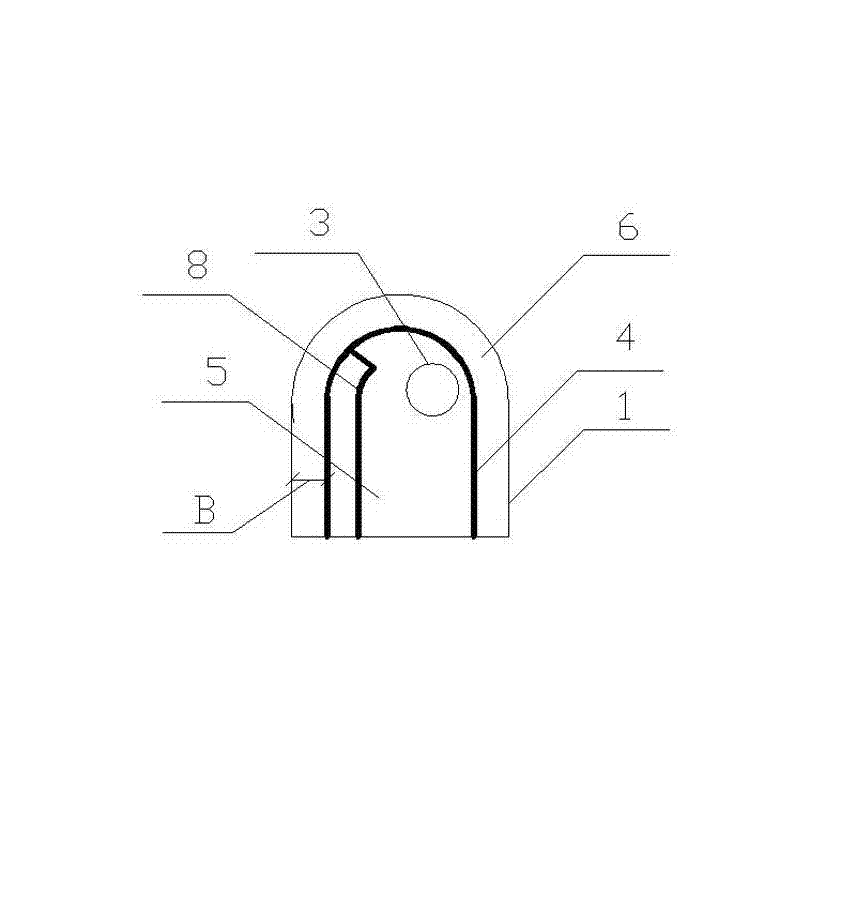

[0039] see figure 1 , figure 2 , the present embodiment includes being arranged in the roadway 1, imitating the shape of the roadway surrounding wall, that is, the shape of the roof and the two states of the roadway, and the heat insulation board 4 with a certain size from the roadway surrounding wall. The heat insulation board 4 is made of heat insulating material with thermal conductivity less than 0.05W / M.K, and is fixed on the roadway support. The heat insulation board 4 divides the roadway 1 into a main channel 5 in the middle of the roadway and a secondary flow channel 6 between the heat insulation board 4 and the surrounding rock of the roadway wall. It can be seen from the figure that the heat shield 4 is located at the end of the excavation face 7 and is connected with an angle-adjustable deflector 8 , the deflector 8 is inclined toward the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com