Grain-oil power generation assembly for silo

A technology for power generation devices and silos, which is applied in the directions of machines/engines, mechanical equipment, and mechanisms that generate mechanical power, and can solve problems such as waste and serious energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

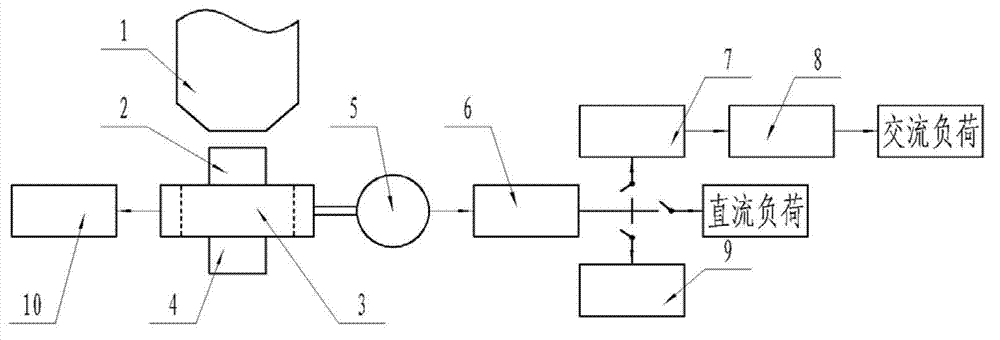

[0020] A silo grain and oil power generation device, comprising a silo 1, the bottom of the silo 1 is provided with an air lock 3 connected with a speed increaser 10, the inside of the air lock 3 is provided with an impeller, and above the impeller is Grain inlet 2, below is the grain unloading port 4; the distance between the axis of the air locker 3 and the center of the grain inlet 2 is greater than the inner radius of the grain inlet 2; the downstream of the air locker 3 is sequentially provided with a generator 5 and a rectifier 6; a storage battery 9 and an inverter 7 are arranged in parallel downstream of the rectifier 6, and a load controller 8 is arranged downstream of the inverter 7.

[0021] The speed inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com