Detecting device and detecting method for residual reflection of covered edges of large-size neodymium glass with covered edges

A technology of residual reflection and detection devices, which is applied in the measurement of scattering characteristics, etc., can solve the problems of large size and specifications, and achieve the effect of low cost, simple structure, and fast automatic measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the drawings and embodiments.

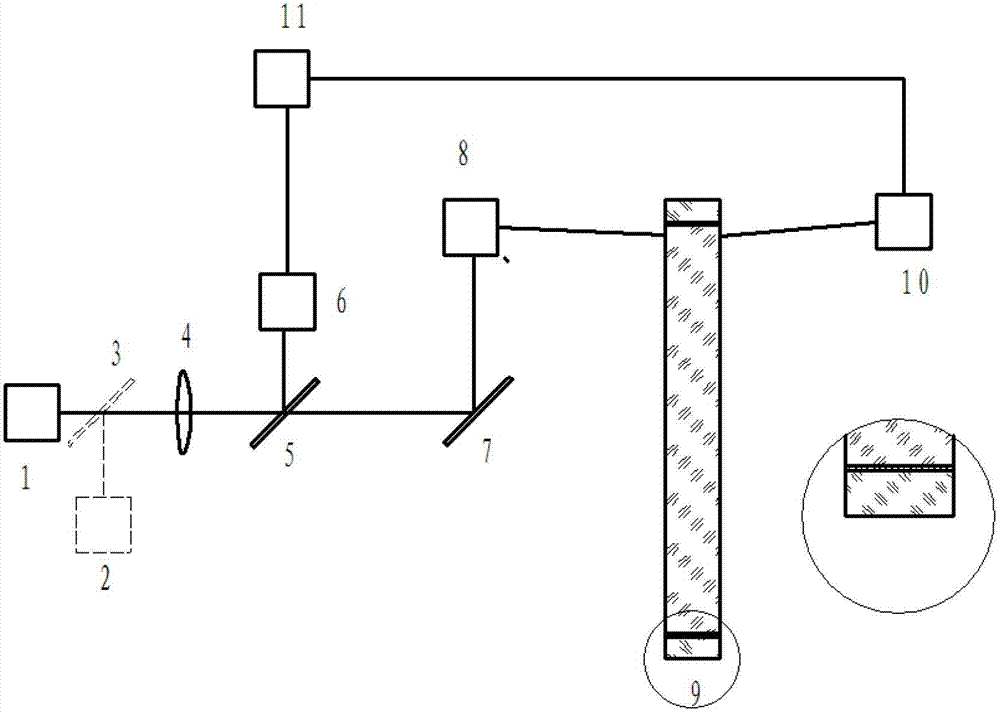

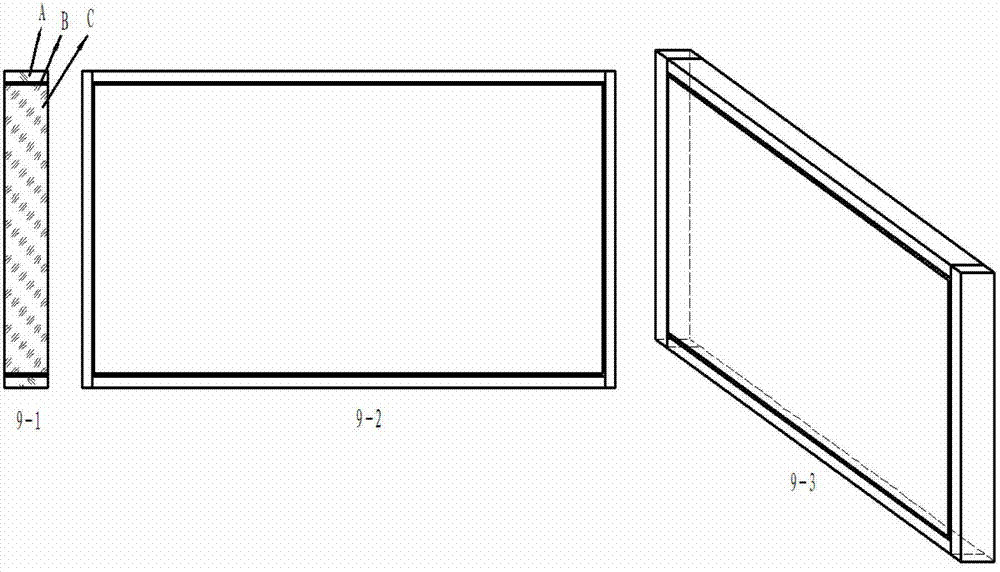

[0030] See first figure 1 , figure 1 It is a schematic structural diagram of an embodiment of the detection device of the present invention. It can be seen from the figure that the detection device for the residual reflection of the edging large-size neodymium glass edging of the present invention includes the first laser light source 1, the beam shaping lens group 4, the beam splitter 5, the first total mirror 7, the beam positioning system 8, and the test For sample 9, laser intensity detector 6, residual reflection detector 10 and data processing system 11, the positional relationship of the above-mentioned components is as follows:

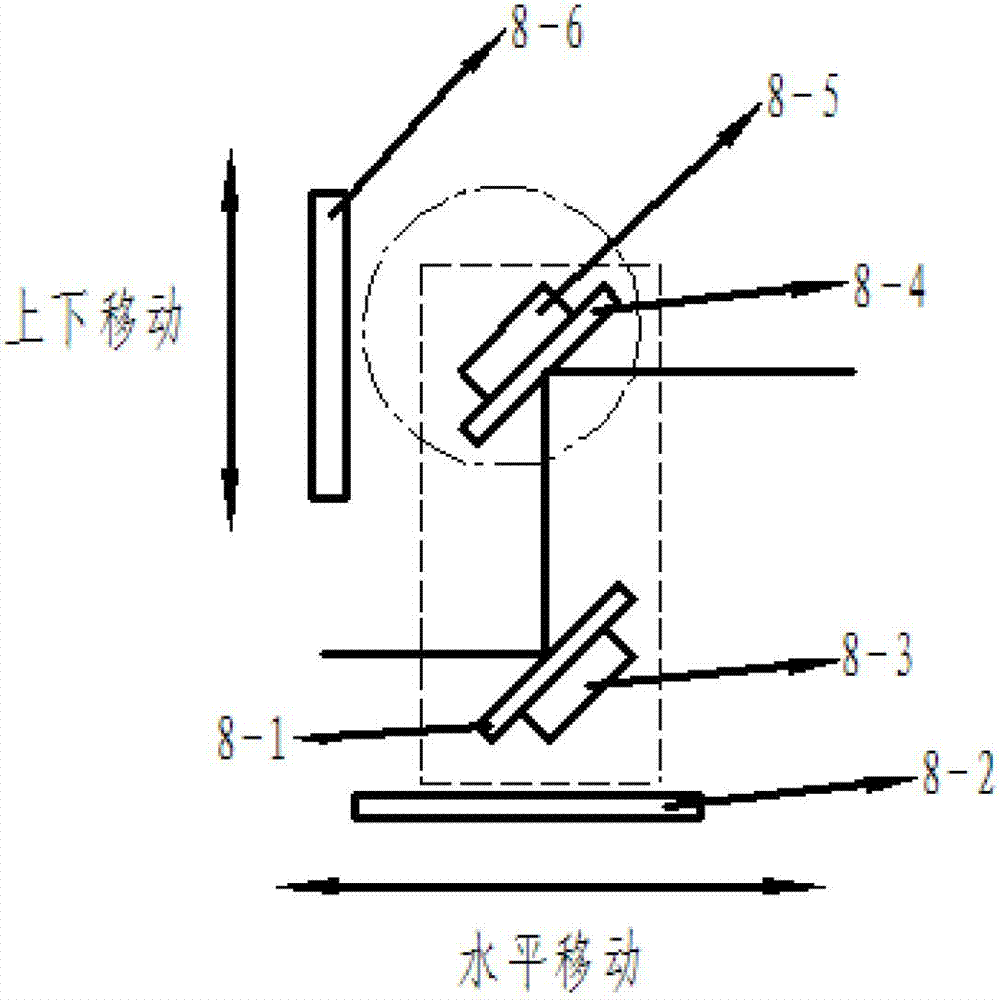

[0031] Along the laser output direction of the first laser light source 1 are the beam shaping lens group 4 and the beam splitter 5 in turn. The beam splitter 5 divides the incident light into transmitted light and reflected ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com