Optimization method for topography of soldering diamond-impregnated grinding wheel of high-speed railway track plate

An optimization method, diamond technology, applied in the direction of grinding devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of limited performance improvement of grinding wheels and no theoretical system guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] specific implementation plan

[0053] To make high-speed rail track plate brazed diamond grinding wheel, the specific production method is as follows:

[0054] (1) Clean and polish the base of the grinding wheel to ensure that the surface is free of grease, stains, and rust.

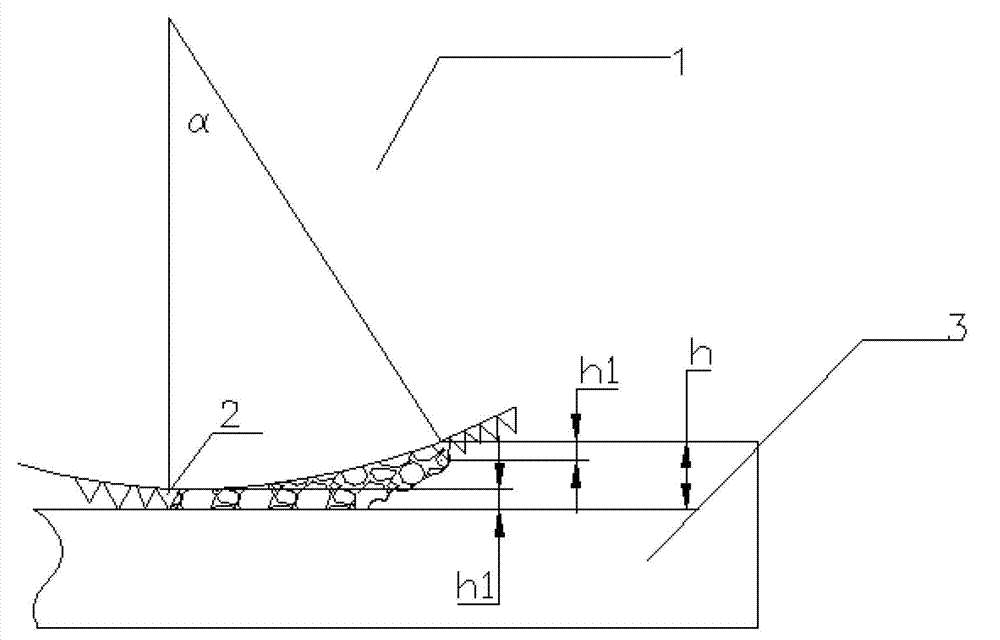

[0055] (2) Use a special fixture to fix the grinding wheel base on the three-jaw chuck. The grinding wheel on this fixture can realize axial rotation and axial tilting and other actions.

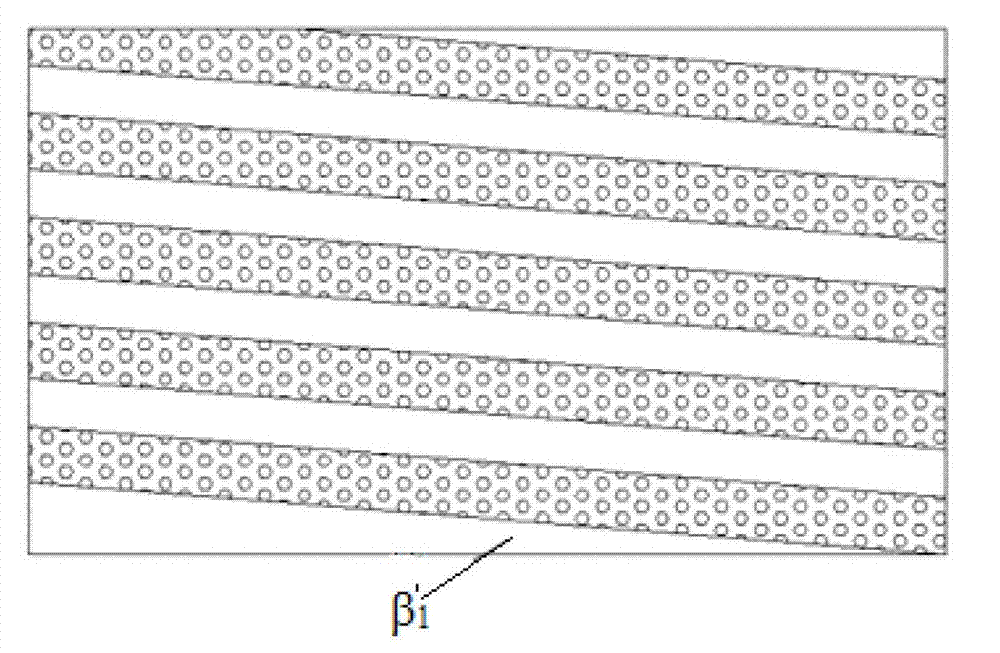

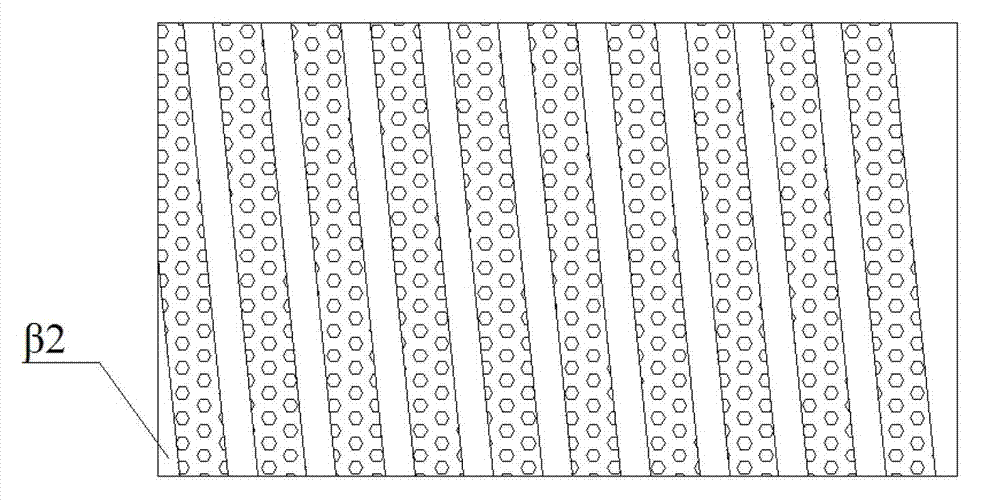

[0056] (3) Arrange the abrasives on the surface of the grinding wheel base according to the designed landform optimization plan. The area where the abrasives are arranged is first indexed with an indexing tape according to the optimal distribution number of 89 segments, and the inclination angle is 55 degrees. The area occupied by the tape is the width of the flute; then the adhesive is coated at the interval of the tape to provide a certain viscosity; then the diamond is evenly distributed on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com