Preparing method for foulant-resisting, water-absorbing and anti-static shell fabric

An anti-static fabric and fabric technology, applied in the field of fabrics, can solve problems such as unscientific production process, complex structural design, and inefficiency, and achieve super water absorption and decontamination performance, scientific preparation process, and good anti-static function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

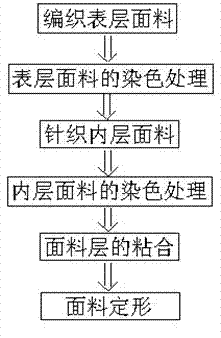

Image

Examples

Embodiment

[0018] The specific preparation method is as follows:

[0019] a) Weave the surface fabric. The raw material of the surface fabric is 8.3 tex / 72F polyester-nylon composite fiber. The yarn ratio of the composite fiber is: polyester 62%-81%, nylon 19%-38%. The surface fabric is woven by a four-bar warp knitting machine, with a warp knitting density of 55 and a vertical density of 70, and a gray fabric weight of 198g / m 2 . During weaving, the polyester-nylon blended yarn is divided into eight petals by orange segment technology, which increases the surface area of the polyester-nylon fiber, increases the pores in the fabric, and enhances the water absorption effect by means of the capillary wicking effect; at the same time, the blended fabric adopts a special cross-section, And the fineness of polyester nylon fiber is 75D, so it can effectively capture fine dust particles, and the effect of decontamination and oil removal is very obvious.

[0020] b) Dyeing treatment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com