Synthetic method of novel mesoporous-microporous NaY zeolite

A synthesis method and molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of small molecules, inappropriate ratio of polymer to silicone modifier, etc., and achieve synthesis cost The effect of reducing, saving operation time, and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of silane modifier MP-20000

[0038] Step 1: Dissolve 0.50g of 3-(2.3-glycidyloxypropoxy)propyltrimethoxysilane (GPMS) (2.12mmol) and 10.6g of polyethyleneimine (0.53mmol) in 8g of solvent and react at 100°C 24h.

[0039] Step 2: The resultant is evacuated with a rotary evaporator to remove ethanol, so as to obtain the silane modifier MP-20000.

Embodiment 2

[0040] Embodiment two: the preparation of meso-microporous NaY molecular sieve

[0041] Step 1: Weigh 72.13g of water glass and 15.83g of directing agent into a 250ml flask; weigh 6.00g of MP-20000 and dissolve in 4.25g of TMOAH; weigh 8.00g of NaOH and NaAlO 2 : 1.00g is put into the beaker, dissolves (lye) with 45ml deionized water; Weigh Al 2 (SO 4 ) 3 : Put 21.88g into a beaker and dissolve with 40ml deionized water;

[0042] Step 2: Add the mixture of MP-20000 and TMOAH into the flask, then add lye, adjust the pH value, and finally add Al dropwise 2 (SO 4 ) 3 ; when Al 2 (SO 4 ) 3 Halfway through the dropwise addition, increase the speed to make the gel react evenly; after the dropwise addition, keep stirring at 25°C for 1 hour;

[0043] Step 3: Stop stirring and crystallize in a kettle at 110°C for 24 hours;

[0044] Step 4: cooling, suction filtration, drying, and calcination to obtain mesoporous NaY molecular sieve

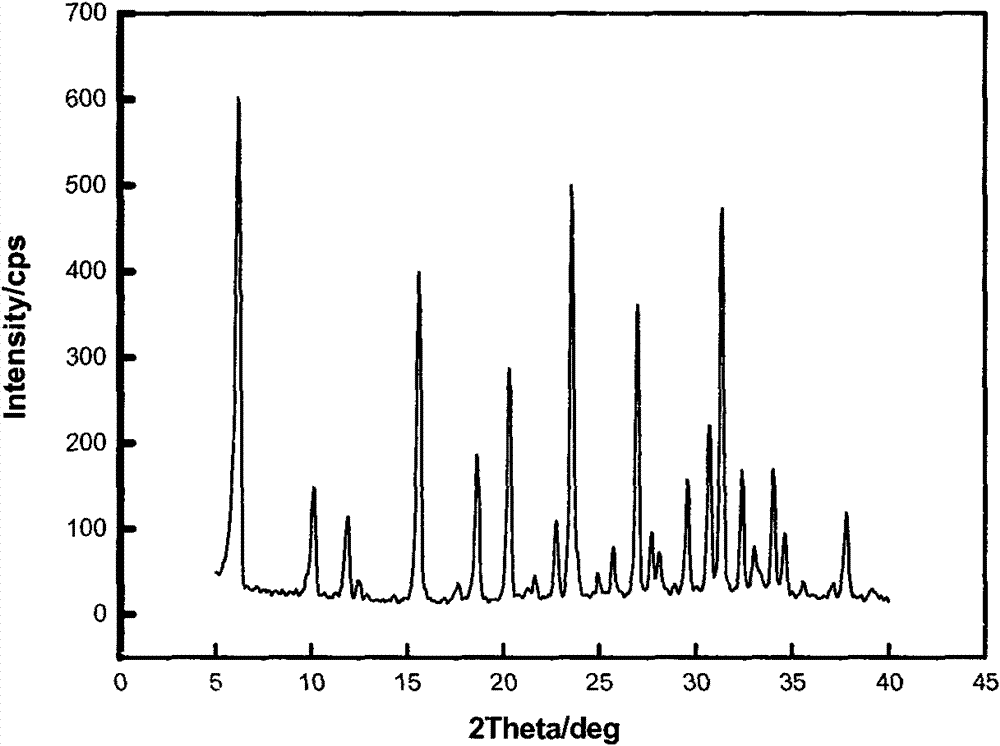

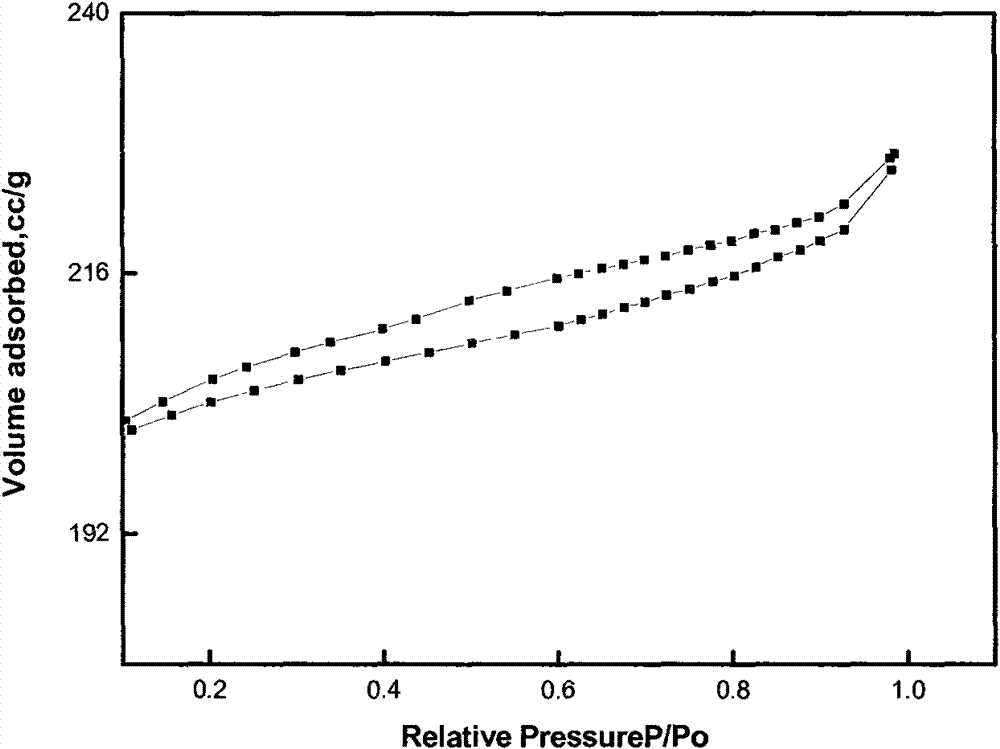

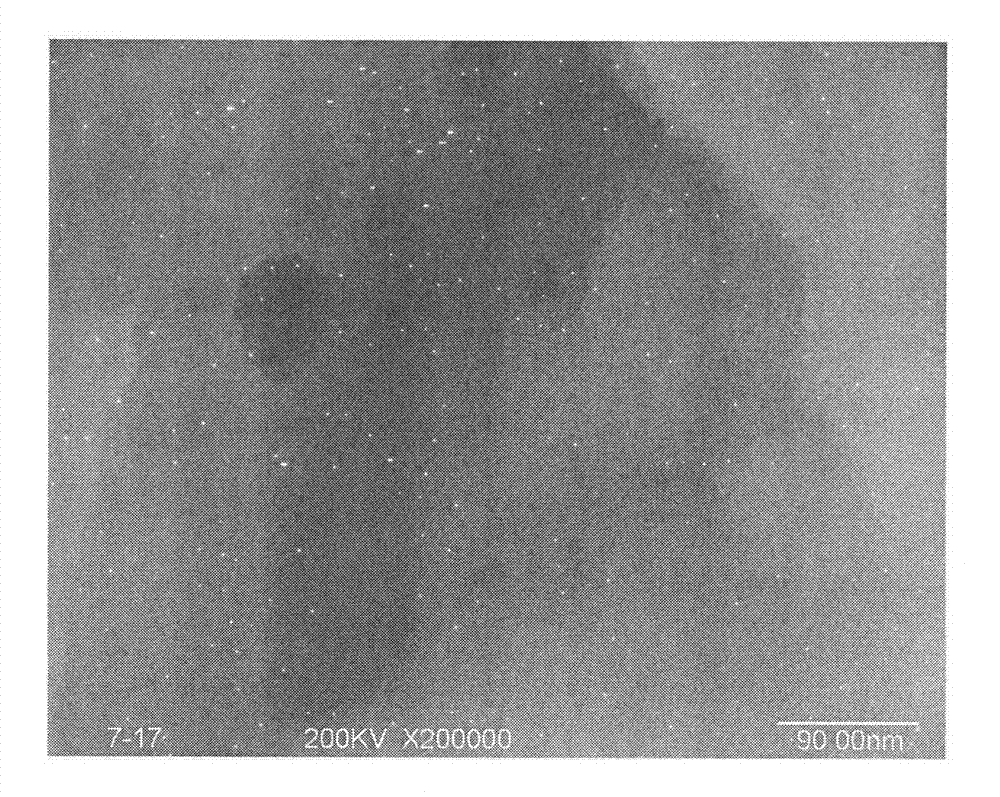

[0045] Step 5: Characterization: use XRD ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap