Environment-friendly halogen-free flame retardant liquid and preparation method thereof

A flame retardant liquid and environmental protection technology, applied in the field of environmentally friendly halogen-free flame retardant liquid and its preparation, can solve the problems of low flame retardant efficiency, and achieve the effect of high flame retardant efficiency and small usage amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

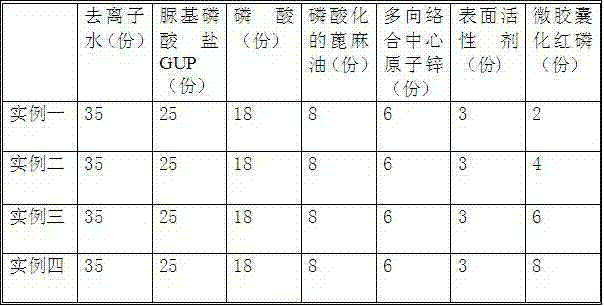

Examples

Embodiment Construction

[0014] Ureidophosphate GUP (10~70%) consists of the following raw materials in mass percentage:

[0015] Phosphorus oxygen acid 10~60%

[0016] Dicyandiamide 10~60%

[0017] Water 30~80%

[0018] Synthesis of ureidophosphate GUP: Install a thermometer, stirring device, reflux condenser and dropping funnel on a 250ml four-necked round bottom flask, add 42 grams of dicyandiamide and 60ml of water, heat to 60°C to make dicyandiamine Dissolve; Add 0.25 mol of phosphorous acid and hypophosphorous acid with a concentration of 85% dropwise from the dropping funnel under stirring, and react at a temperature of 95°C until the complete transformation of dicyandiamide takes 25 minutes, and the judgment of the reaction end point can be According to the change of pH value or using infrared spectroscopy, after the reaction is completed, cooling, filtering, crystallization, drying, and crushing, 140 grams of ureidophosphate GUP is obtained. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com