Fluorine-modified epoxy phosphate aqueous dispersion

A technology of epoxy phosphate ester and fluorine modification, which is applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems that the heat resistance and insulation performance of polymer corrosion-resistant coatings cannot meet the needs of use, and achieve improvement Mechanical properties and heat and corrosion resistance, good manufacturability, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

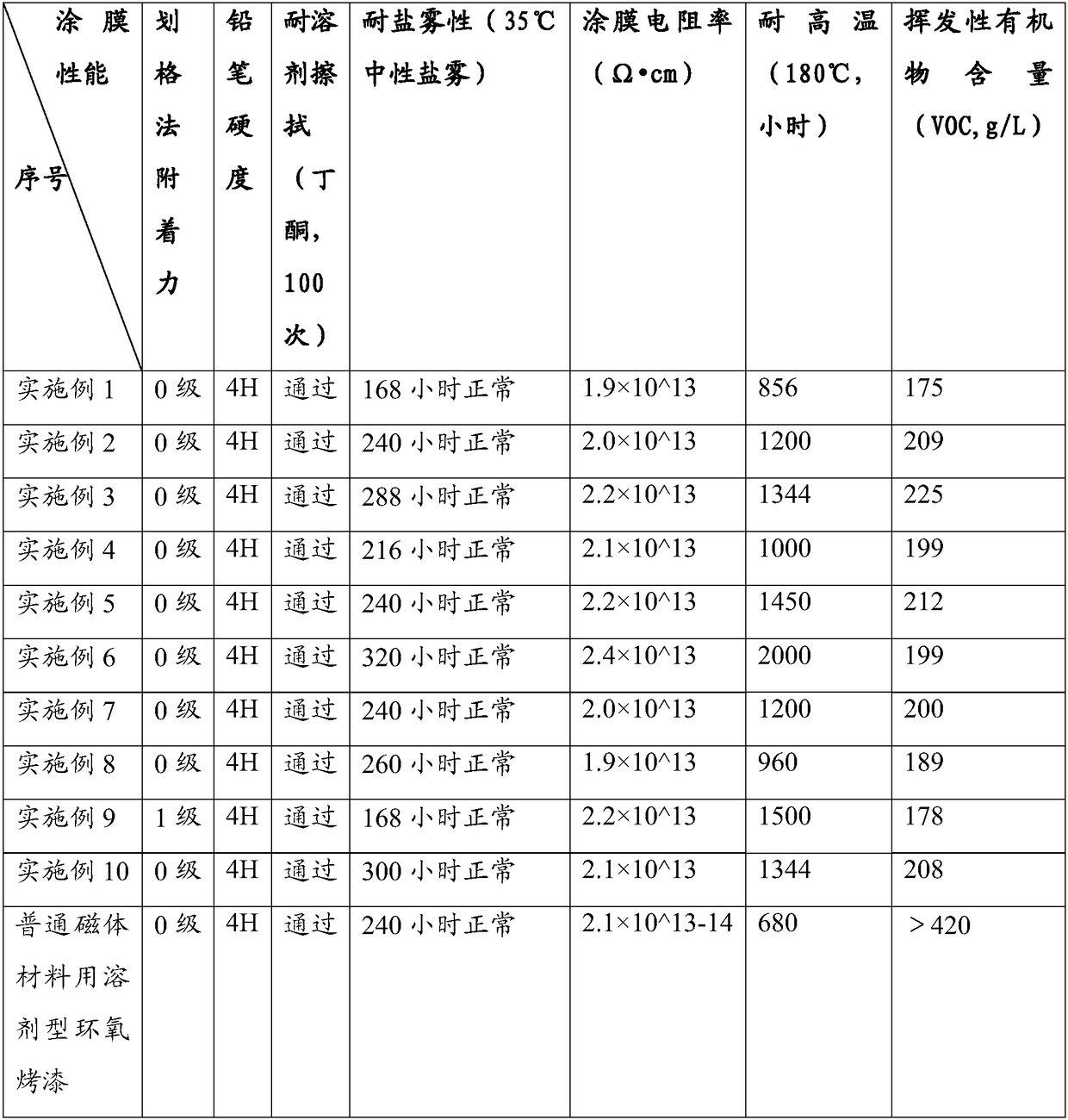

Examples

preparation example Construction

[0028] The second aspect of the present invention provides a kind of preparation method of above-mentioned fluorine-modified epoxy phosphate aqueous dispersion, and this method comprises the following steps:

[0029] (1) Oxazolidinization: Put the epoxy resin, small molecule alcohols and the first catalyst in the formula into the reaction vessel, mix, stir and heat to 30-70°C, then add the isocyanate in the formula at 35- Keep warm at 75°C for 0.5-3 hours, then slowly raise the temperature to 100-130°C, add part of the second catalyst and react at 110-135°C until the epoxy equivalent of the epoxy resin is 252-340. Preferably, the temperature for the first heating is 40-45°C, the temperature for heat preservation is 40-65°C, the time for heat preservation is 1-2 hours, and the temperature for the second heating is 115-125°C. After adding the second catalyst The reaction temperature is 115-130° C., and the epoxy equivalent of the epoxy resin is 310-330 at 115-130° C.

[0030] D...

Embodiment 1

[0044] (1) Take 301g of epoxy resin E51, 9g of methanol, and 0.2g of dibutyltin dilaurate into a reaction vessel, mix, stir and heat to 30°C, then add 130g of modified diphenylmethane diisocyanate of Desmodur E22 Keep warm at 35°C for 0.5-1 hour, slowly heat up to 100°C, add 0.35g of triphenylphosphine and react at 110°C until the epoxy equivalent of the epoxy resin is 320-330;

[0045] (2) Add 30g of ethylene glycol monobutyl ether and cool down to 75°C, add 95g of bisphenol A, 35g of bisphenol AF and 0.35g of triphenylphosphine, raise the temperature to 140°C under stirring, and react to the temperature of the epoxy resin The epoxy equivalent is 1900-2000;

[0046] (3) Add 190g of ethylene glycol monobutyl ether and cool down to 50°C, then add 35g of phosphoric acid, heat up to 90°C, keep warm for 2-3 hours, then cool down to 55°C, add 63g of N,N-dimethylethanolamine (DMEA) And stir evenly, slowly add 1090g of deionized water at 50-60°C dropwise, and emulsify to obtain a fl...

Embodiment 2

[0050] (1) Take 364g of epoxy resin E51, 11g of ethanol, and 0.21g of monobutyltin oxide in a reaction vessel, mix, stir and heat to 30°C, then add 158g of modified diphenylmethane diisocyanate of Desmodur E22 Keep warm at 36°C for 0.5-1 hour, slowly heat up to 110°C, add 0.42g of N,N-dimethylbenzylamine and react at 115°C until the epoxy equivalent of the epoxy resin is 318-328;

[0051] (2) Add 56g of ethylene glycol monobutyl ether and cool down to 80°C, add 44g of bisphenol A, 133g of bisphenol AF and 0.42g of N,N-dimethylbenzylamine, raise the temperature to 135°C under stirring, and react The epoxy equivalent to epoxy resin is 1550-1650;

[0052] (3) Add 185g of ethylene glycol monobutyl ether and cool down to 55°C, then add 51g of phosphoric acid, heat up to 102°C, keep warm for 2-3 hours, then cool down to 60°C, add 78g of N,N-dimethylethanolamine (DMEA) And stir evenly, slowly add 1200g of deionized water at 60-70°C dropwise, and emulsify to obtain a fluorine-modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com