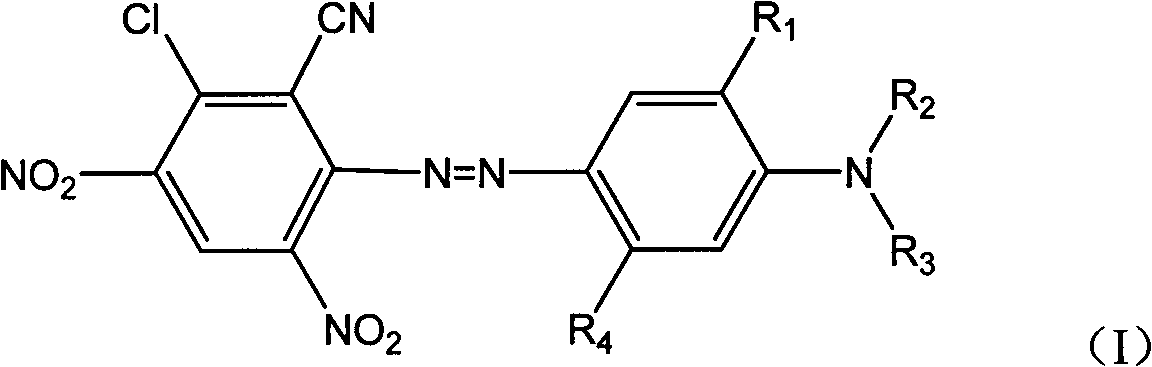

Cyano-containing azo disperse dye

A technology of disperse dyes and azo, applied in the preparation of azo dyes, azo dyes, organic dyes, etc., can solve the problem of difficult to obtain dark color, and achieve excellent moisture resistance, good temperature dependence, and excellent sublimation fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

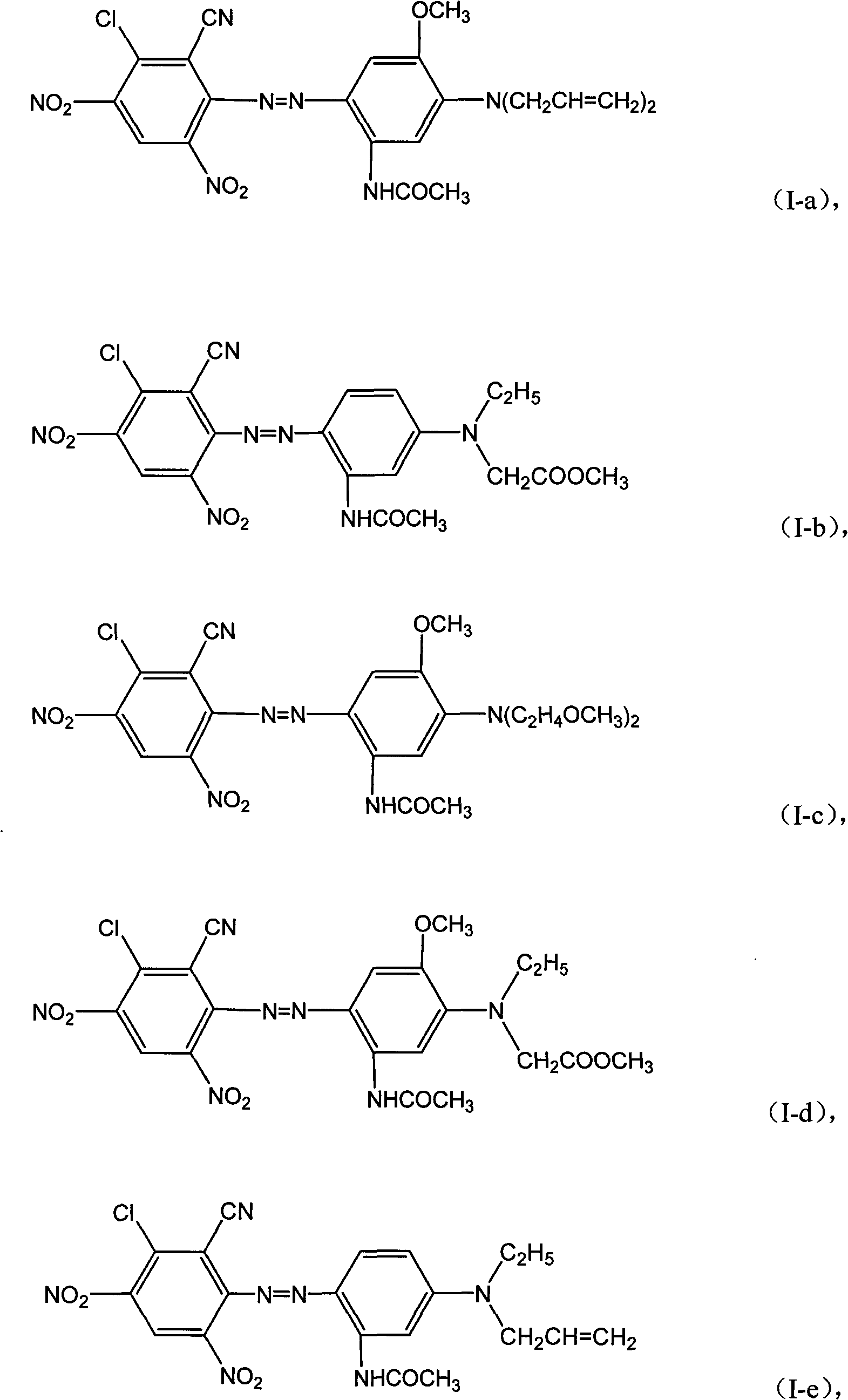

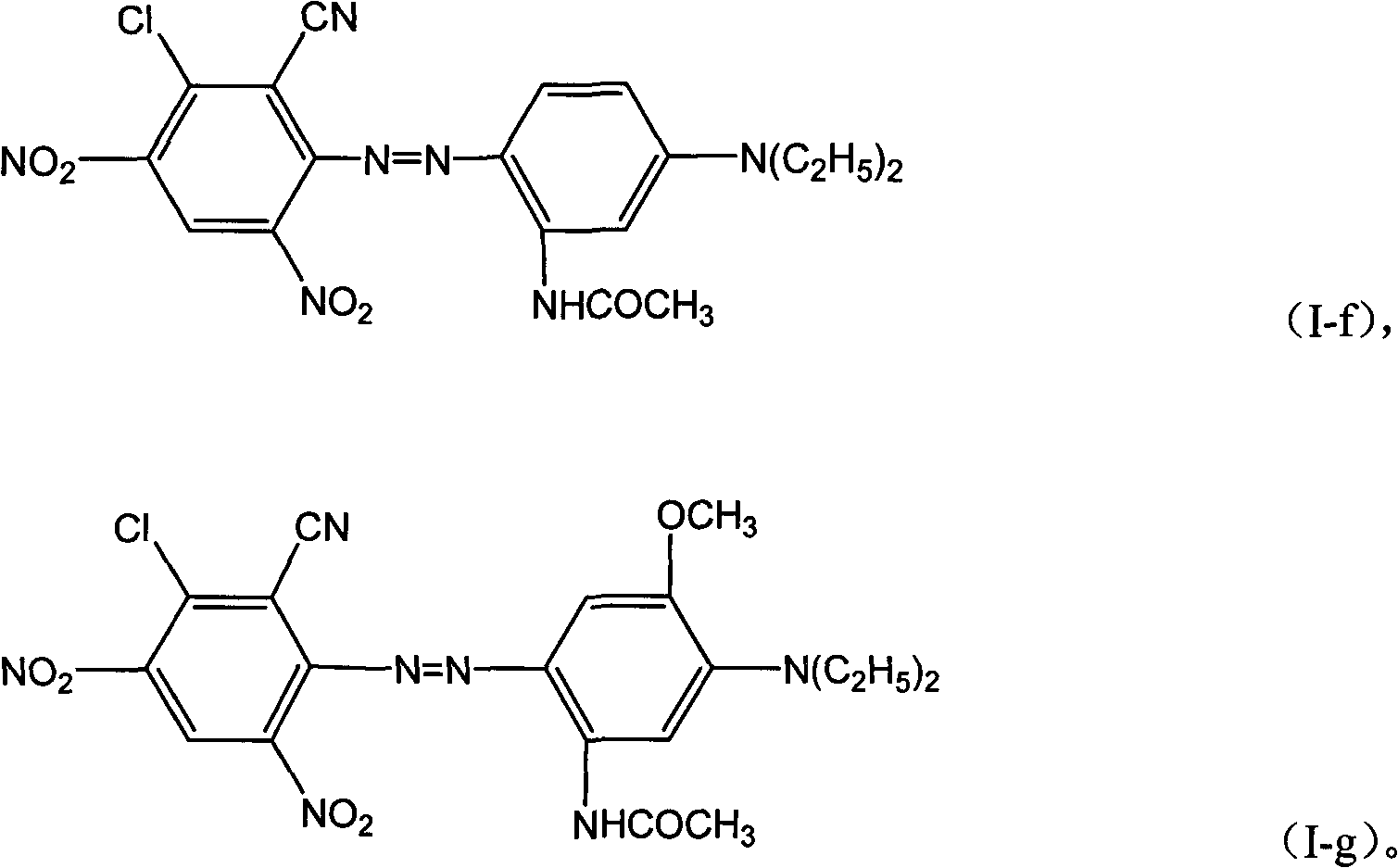

Examples

Embodiment 1

[0024] Add 55 milliliters of sulfuric acid in the three-necked flask, dropwise add 13 grams (100%) of nitrosyl sulfuric acid, add 2-bromo-3-chloro-4,6-dinitroaniline 29.65 grams at room temperature, stir and react for 4 hours, After the diazonium reaction was completed, it was added dropwise to the mixture consisting of 10 milliliters of sulfuric acid, 500 grams of ice water and 25 grams of compounds shown in formula (II-1),

[0025] Formula (II-1)

[0026] After the addition, continue to react for 1 hour, add 500 ml of water, raise to 50°C and keep warm for 1 hour, filter with suction, wash with hot water, dry, and wait for cyanation.

[0027] Add 100 ml of DMF, 10.8 g of cuprous cyanide, and 55 g of the drying dye mentioned above into a three-necked flask, and heat up to 100°C for 2 hours. After TLC monitoring reaches the end of the reaction, cool down to 30°C and add 50 g of ice, and the cyanide product precipitates , filter, wash with water, obtain the azo dyes containi...

Embodiment 2

[0031] Add 50 milliliters of sulfuric acid in the three-necked flask, dropwise add 13 grams (100%) of nitrosyl sulfuric acid, add 2-bromo-3-chloro-4,6-dinitroaniline 29.65 grams at room temperature, stir and react for 4 hours, After the diazonium reaction was completed, it was added dropwise to the mixture consisting of 10 milliliters of sulfuric acid, 500 grams of ice water and 19 grams of compounds shown in formula (II-2),

[0032] Formula (II-2)

[0033] After the addition, continue to react for 1 hour, rise to 60°C and keep warm for 1 hour, filter with suction, wash with water, dry, and wait for cyanation.

[0034] Add 100 ml of DMF, 10.8 g of cuprous cyanide, and 49 g of the above drying dye to a three-necked flask, and heat up to 80°C for 2 hours. After TLC monitoring reaches the end of the reaction, cool down to 20-30°C, add 60 g of ice, cyanide The compounded product separates out, filters, washes, obtains the azo dye containing cyanoaniline as shown in formula (I-h...

Embodiment 3

[0038] The compound shown in (II-2) in the replacement embodiment 2 is replaced by the compound shown in formula (II-3), and other methods are with embodiment 2,

[0039] Formula (II-3)

[0040] Obtain the azo dyes containing cyanoaniline shown in formula (I-i):

[0041] Formula (I-i)

[0042] The polyester and spandex blended fibers are dyed to obtain purple dyed products with excellent fastness properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com