Gear rack travelling oil extraction machine

A rack-and-pinion, walking-type technology, applied in the direction of belts/chains/gears, mechanical equipment, mining fluids, etc., can solve the problems of low power utilization of motors, difficulty in achieving long strokes, and large torque fluctuations in reducers, etc., to achieve Reduced footprint, good dynamic performance, and smooth motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

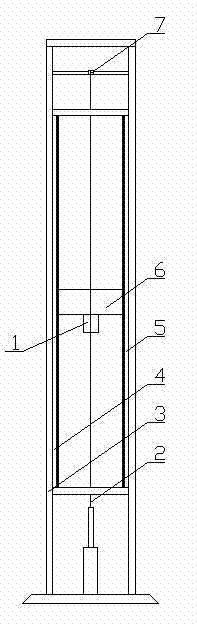

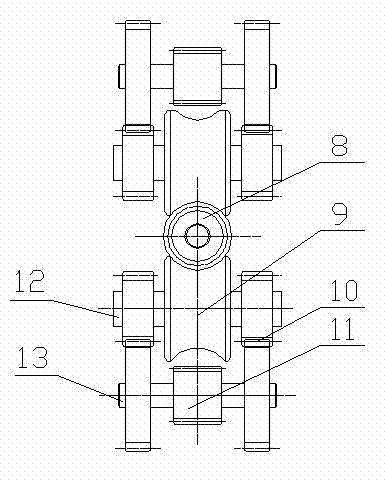

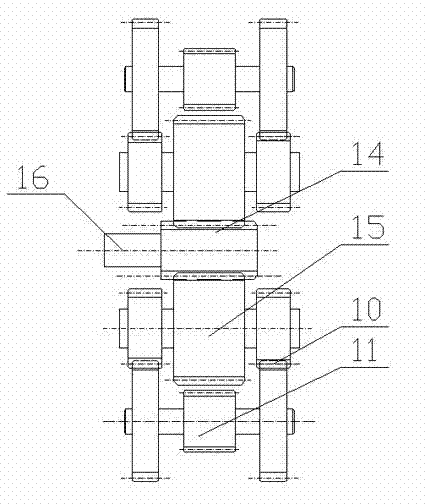

[0018] A rack-and-pinion walking oil lifter mainly consists of a motor 1, a steel wire rope 2, a tower frame 3, a left vertical rack 4, a right vertical rack 5, a variable-speed traveling mechanism 6, and a fixed pulley 7. The positive and negative rotation of the motor drives the gear shifting travel mechanism 6 to reciprocate up and down along the fixed left vertical rack 4 and right vertical rack 5 on the tower 3, driving the steel wire rope 2 and pulling the oil lifting rod to reciprocate.

[0019] The left vertical rack 4 and the right vertical rack 5 are fixed on the tower frame 3, and the travel gear of the gear shifting running mechanism 6 meshes with the left vertical rack 4 and the right vertical rack 5, and the gear shifting running gear 6 One end of the motor is connected with the motor 1, and the other end is connected with the steel wire rope 2, and the steel wire rope 2 is connected with the oil lifting rod. The motor 1 adopts a forward and reverse motor. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com