Normal position zero gas back-blowing type CEMS (continuous emission monitoring system) probe on-line calibration method and device

An on-line technology for calibration devices and probes, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as the inability to balance the intake of flue gas, and achieve avoiding direct contact with flue gas, long service life, and guaranteed reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

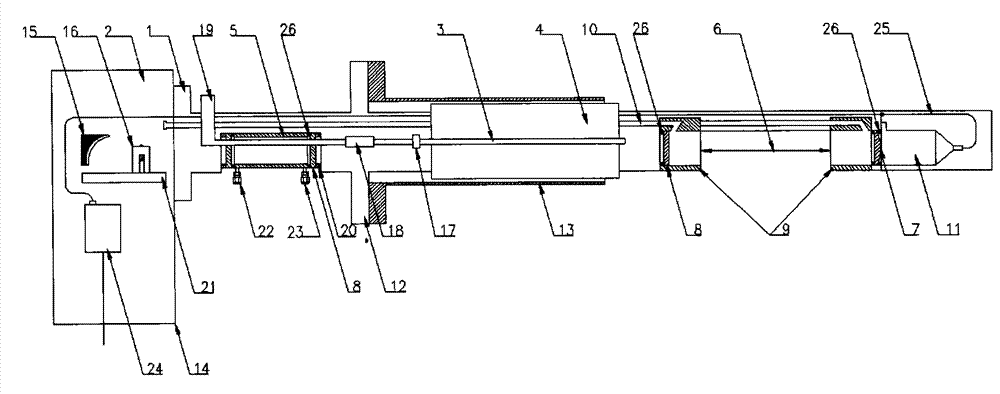

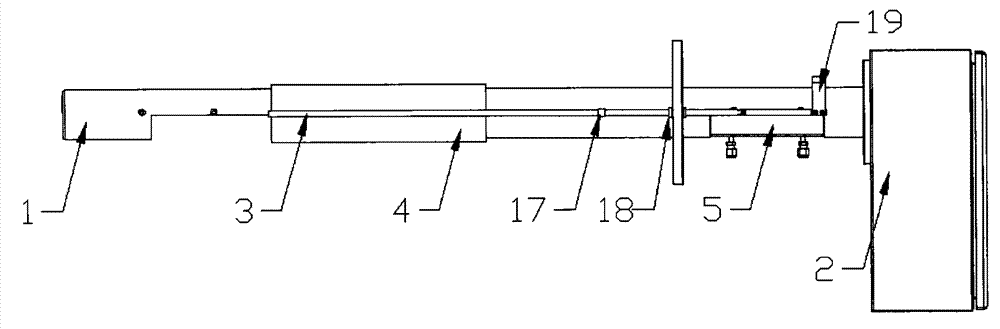

[0048] Embodiment: As shown in the figure, an in-situ zero-gas blowback CEMS probe online calibration device includes a direct-measurement flue gas probe 1, a probe chassis 2, a blocking device and a calibration pool 5;

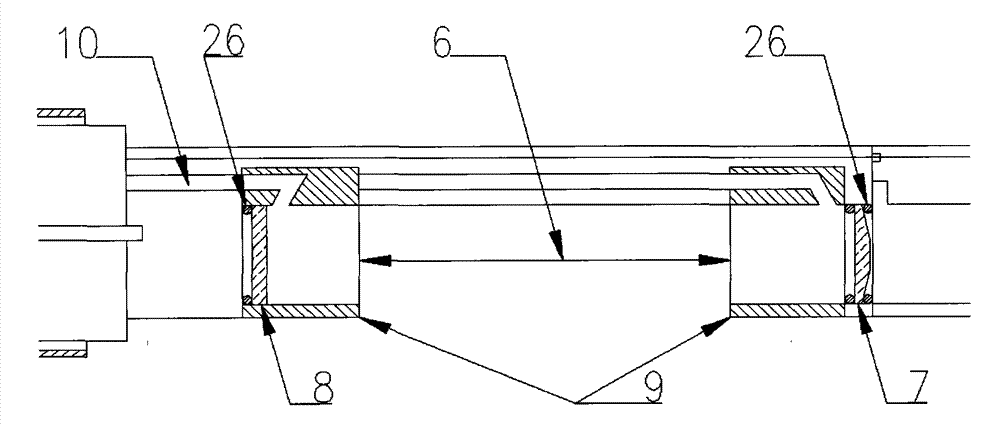

[0049] The direct-measurement flue gas probe 1 is a pipe body, and its front end is provided with a measurement area 6. The measurement area is a measurement port with an opening downward, and air curtain generators 9 are respectively embedded in the probes 1 before and after the measurement area. , the air curtain generator 9 communicates with the purified compressed air input pipe 10; wherein, the air curtain generator 9 located at the rear end of the measurement area 6 is embedded with an ultraviolet quartz window 8, and the ultraviolet quartz window 8 is sealed with an O-ring 26 and is located at the probe 1 There is an ultraviolet quartz lens 7 embedded in the groove at the top, and the ultraviolet quartz lens 7 is sealed with an O-ring 26; a convex lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com