Silicon substrate-based quartz resonance acceleration sensor chip with four-beam structure

An acceleration sensor, beam structure technology, applied in the direction of measuring acceleration, velocity/acceleration/impact measurement, instruments, etc., can solve the problems of low sensitivity, complex structure, low resonance frequency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

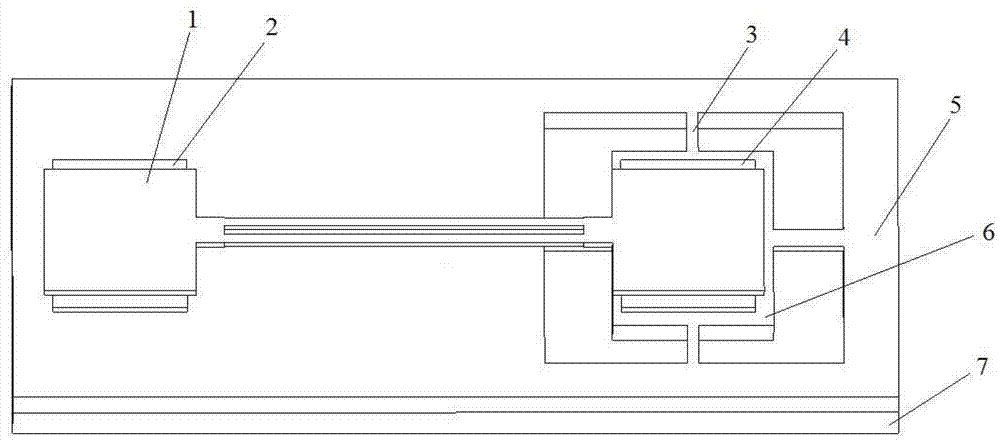

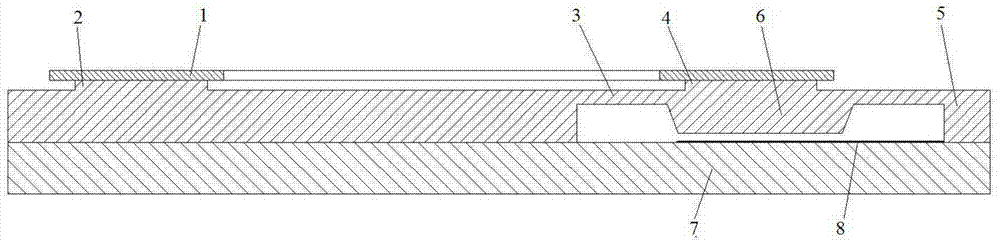

[0017] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

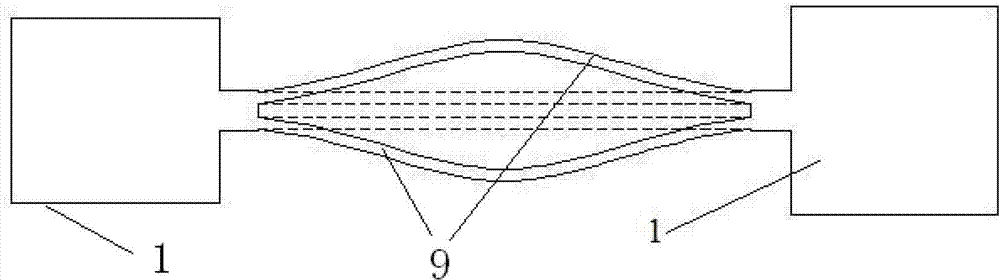

[0018] see figure 1 A silicon-based four-beam structure quartz resonant acceleration sensor chip includes a peripheral silicon-based support 5 with a glass substrate 7 at the bottom, and the peripheral silicon-based support 5 and the glass substrate 7 are connected by bonding. A double-ended quartz tuning fork 1 is fixed on the A silicon boss 2 of the silicon-based support 5 through organic glue, and the other end of the double-ended quartz tuning fork 1 is fixed on the B silicon boss 4 of the mass block 6, and the mass block 6 has four cantilevers The beam 3 is supported on a silicon base 5 . The sensor chip senses the acceleration input through the mass block 6, and then converts the acceleration into an electrical signal through the frequency change of the double-ended quartz tuning fork 1 through the frequency detection cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com