Brushless direct current motor

A brushed DC motor and armature winding technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, winding conductor shape/style/structure, etc., can solve problems that are not given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

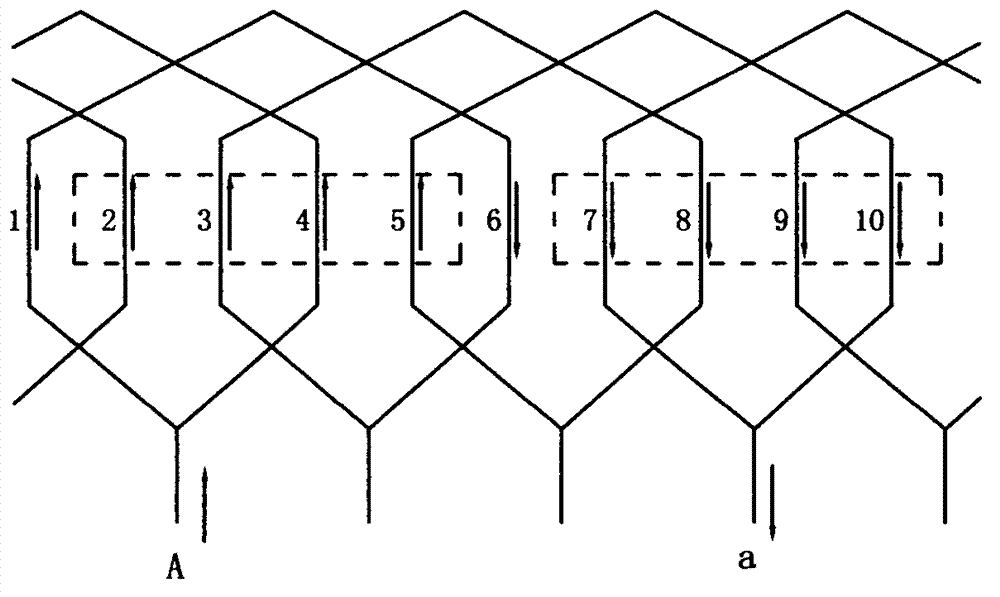

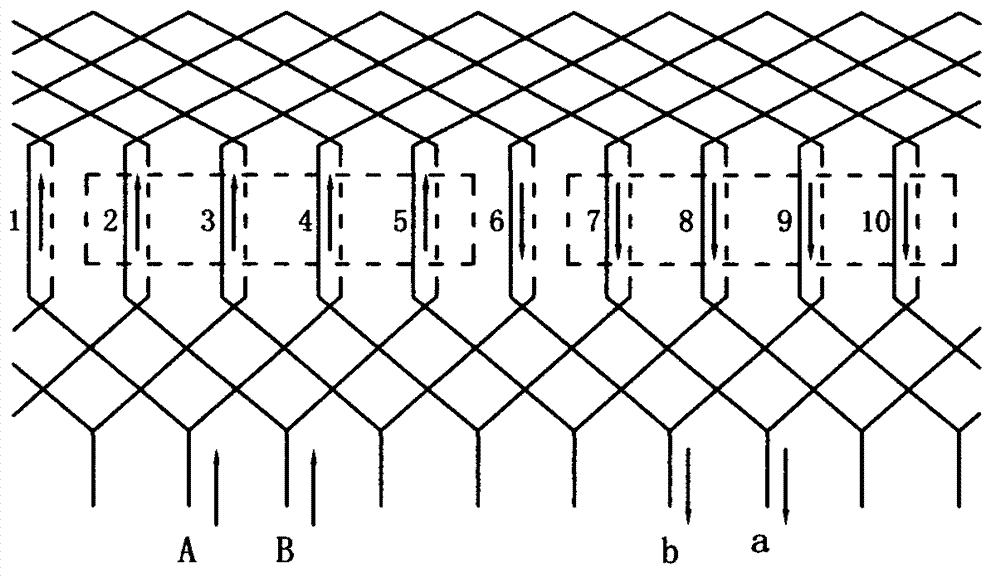

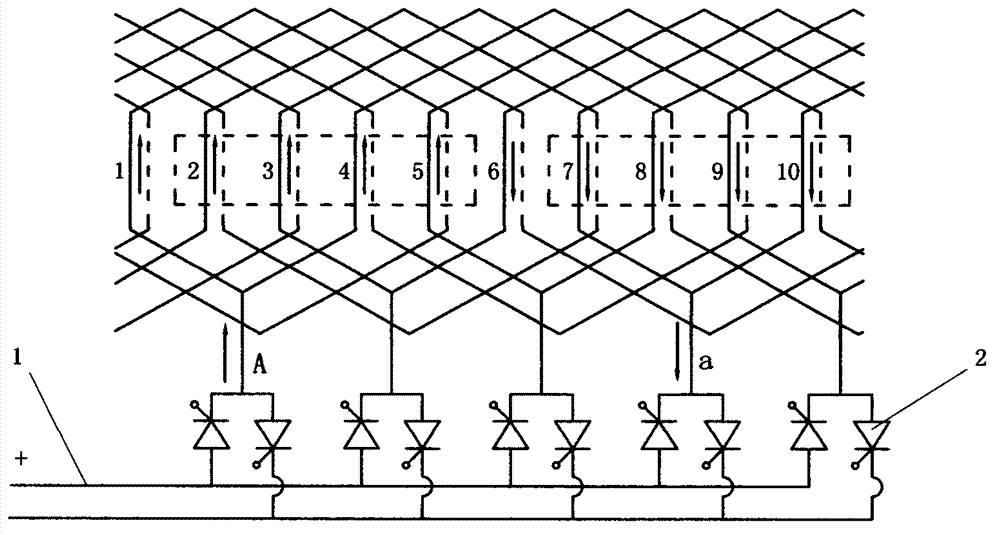

[0013] Such as figure 1 Shown is a 2-pole 10-slot single-layer composite winding expansion diagram, which is disclosed in the Chinese invention patent of "Brushless DC Motor and Its Commutation and Control Method" with the application number: "2005101244451". It has only 5 leads The wire can use 5 pairs of power electronic switching devices for commutation, which has the advantage of using a small number of power electronic switching devices, but the winding ends are inconvenient to arrange or require long ends. figure 2 It is an expanded diagram of a double-layer laminated winding with 2 poles and 10 slots. As an existing technology used in ordinary brushed DC motors, it has been published in some documents. It has 10 lead wires, which need to be used when commutating with power electronic switching devices. Using 10 pairs of power electronic switching devices, using too many power electronic switching devices is its biggest shortcoming. figure 1 , figure 2 It is drawn as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com