Intelligent compound control system for thermal keying installation for magnetic yoke of rotor of large hydrogenerator

A hydro-generator and composite control technology, applied in the direction of manufacturing stator/rotor body, etc., can solve the problems of uneven temperature inside and outside the yoke, large error, long cycle and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

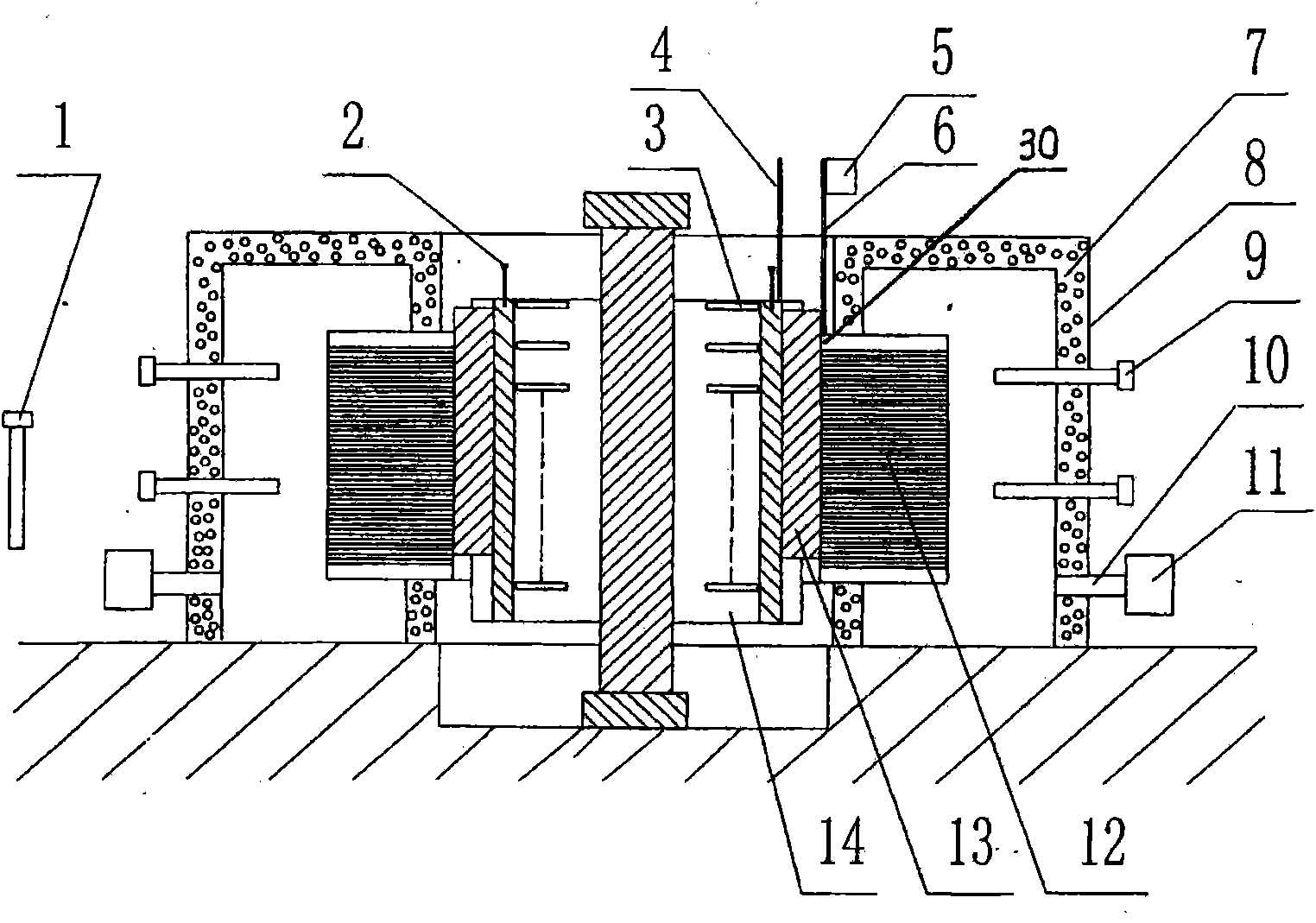

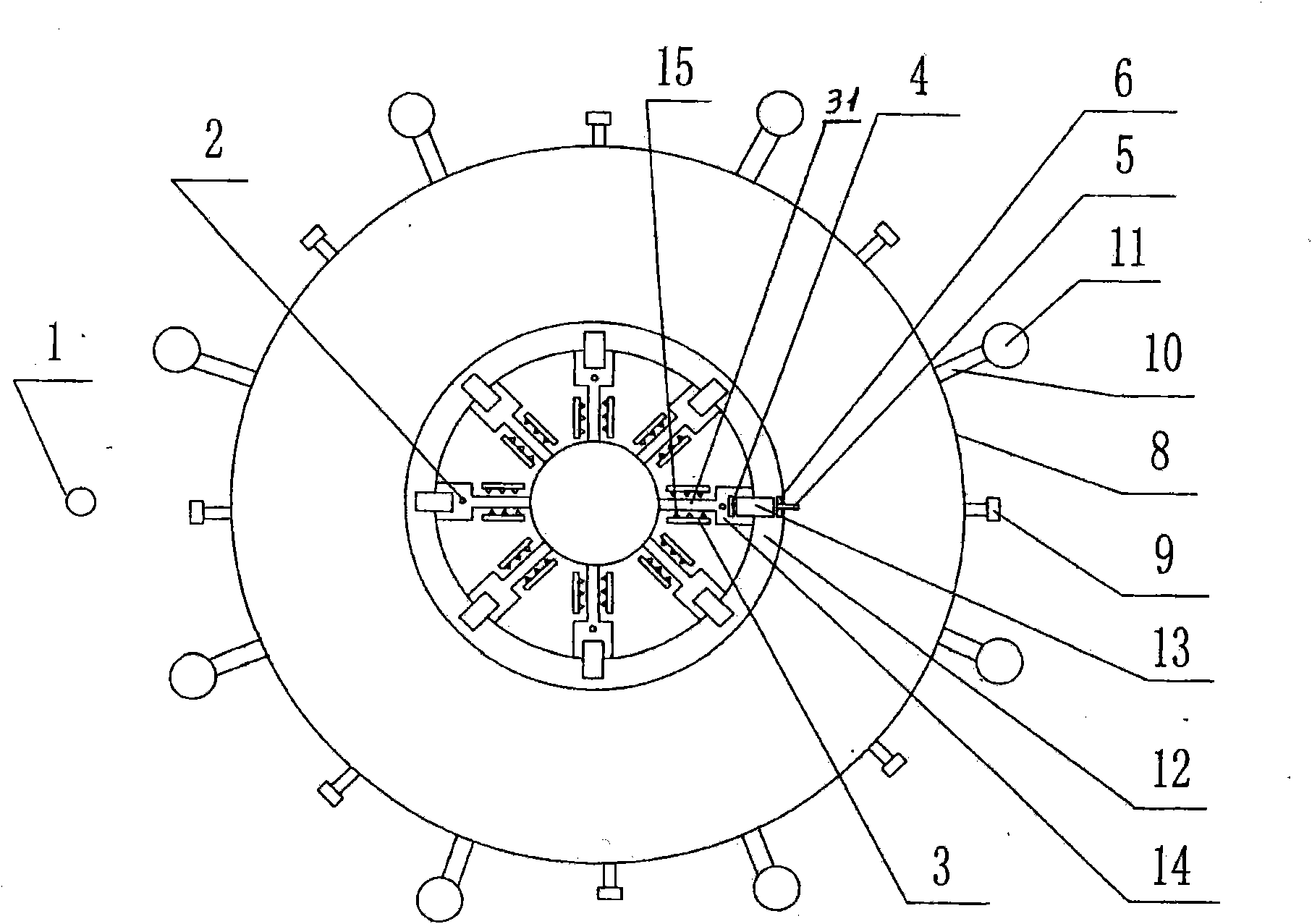

[0026] Example 1, combining figure 1 , figure 2 , image 3 , The hot-keying installation of the rotor yoke of the large-scale hydroelectric generator of the present invention is composed of a heat-insulating shell (8), a yoke assembly (30), a yoke key (13) and a rotor arm assembly (31). The housing (8) is connected with the yoke assembly (30), the yoke assembly (30) is connected with the yoke key (13), and the yoke key (13) is connected with the rotor arm assembly (31).

[0027] The hot-keyed installation of the rotor yoke of the large-scale hydroelectric generator of the present invention has the following technical features:

[0028] The thermal insulation shell (8) includes an aluminum silicate thermal insulation layer (7), an industrial furnace temperature measuring platinum resistor (9), an air supply duct (10) and a hot air blower (11), and an aluminum silicate thermal insulation layer (7) Located inside the heat preservation shell (8), the hot air blower (11) is connected w...

Embodiment 2

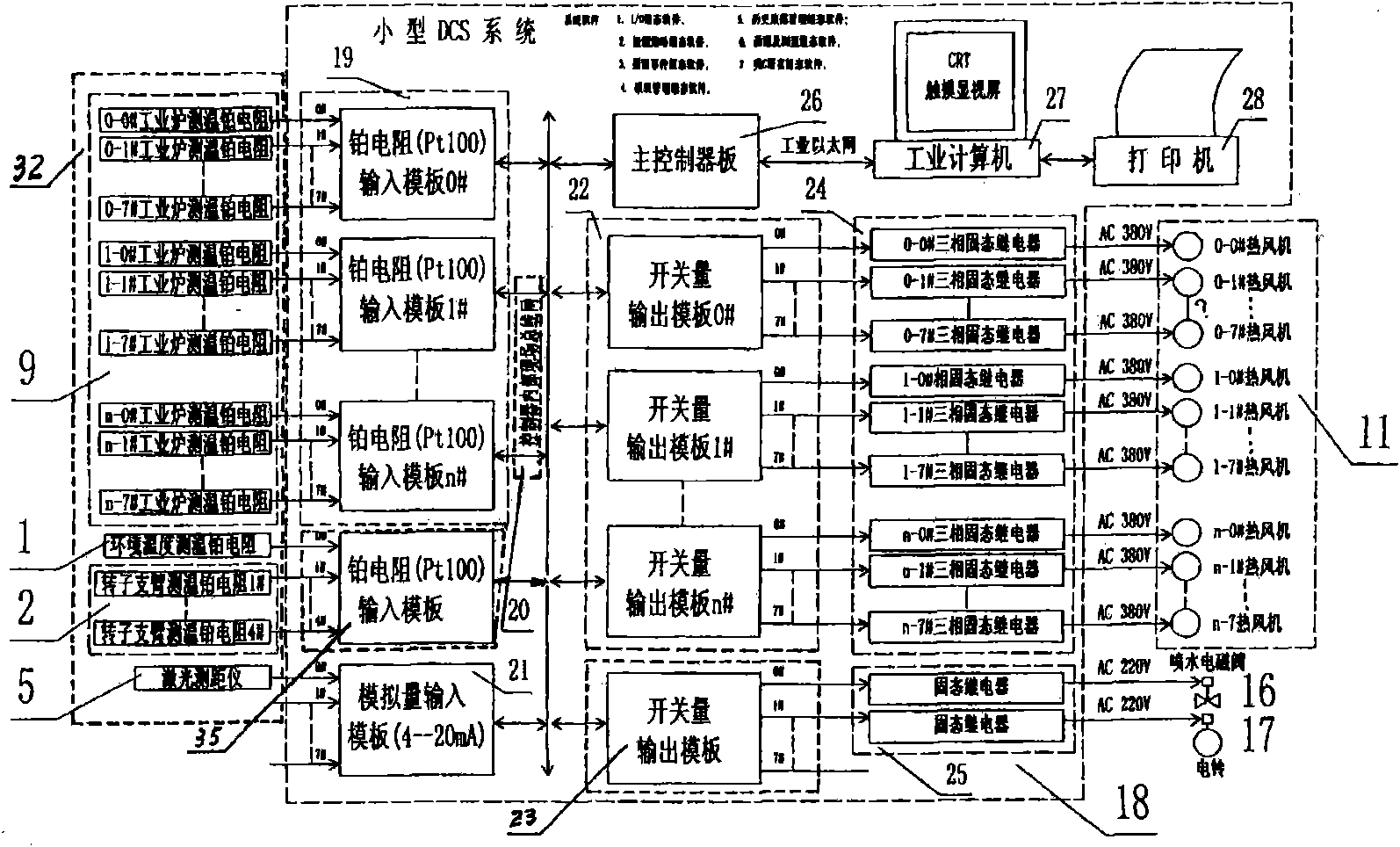

[0037] Example 2, combining Figure 1-Figure 7 , The present invention consists of a thermal insulation shell (8), an aluminum silicate thermal insulation layer (7), a hot air blower (11), an air supply duct (10), an industrial furnace temperature measurement platinum resistance (9), and a rotor arm temperature measurement platinum resistance (2) Ambient temperature temperature measurement platinum resistance (1), spray solenoid valve (16), spray pipe (3), nozzle (15), laser rangefinder (5), laser rangefinder mounting plate (6) ), laser reflector (4), electric bell (17), small DCS system (18) and special software. The specific working process is as follows:

[0038] 1. The working process of the hardware under the function of special software: the closed type magnetic yoke (12) is composed of the thermal insulation shell (8), the aluminum silicate thermal insulation layer (7), the hot air blower (11), and the air supply pipe (10). For the heated industrial furnace, the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com