Apparatus and method for electrochemical treatment of wastewater

A technology for treating wastewater and wastewater, which is applied in chemical instruments and methods, electrochemical water/sewage treatment, water/sewage treatment equipment, etc., and can solve problems such as inability to obtain and use municipal wastewater treatment systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

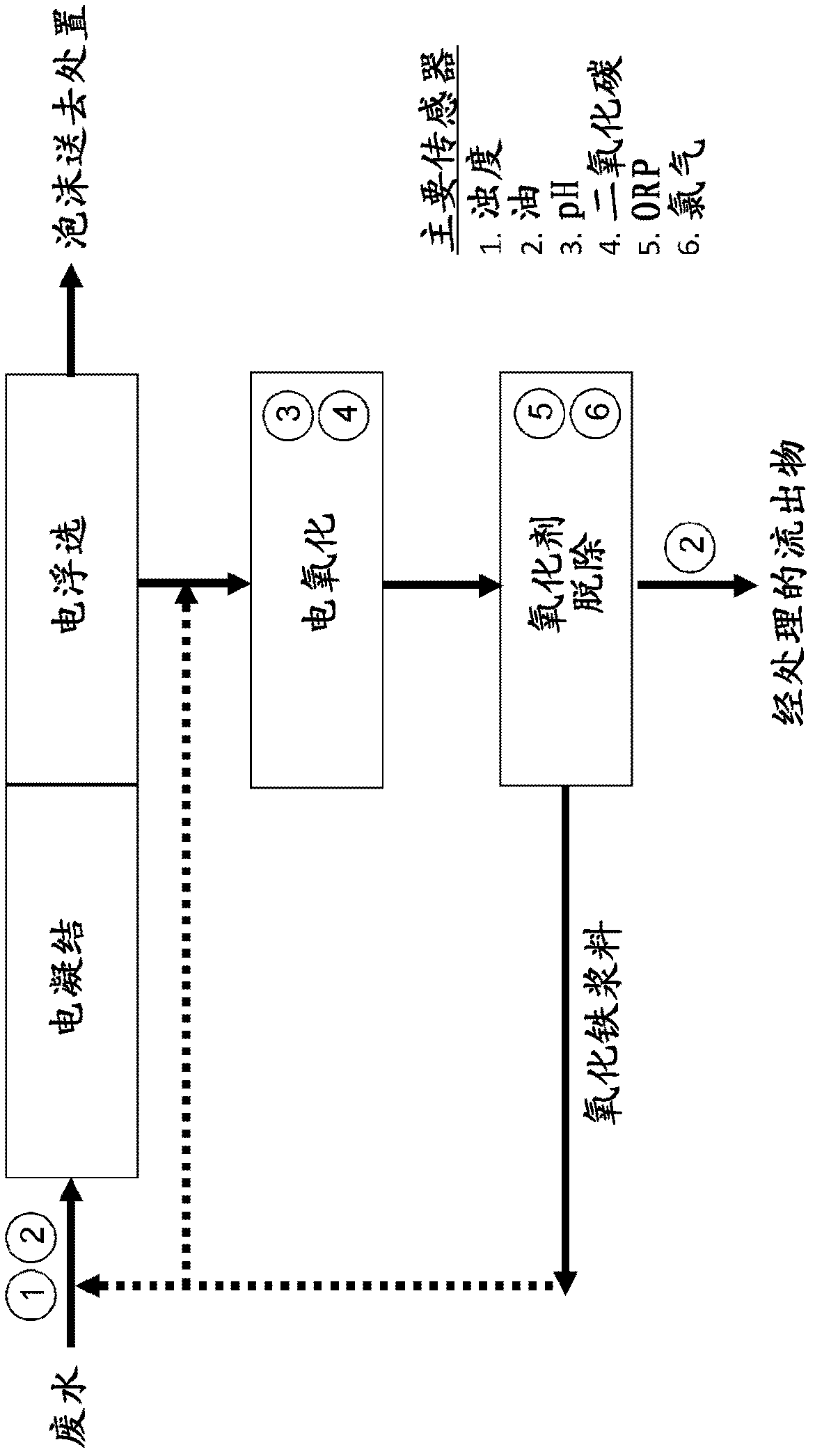

[0031] figure 1 Is a schematic representation of the WETT process including the individual electrochemical processing units, the main on-line sensors where applicable and the recycle of iron oxide to the previous electrochemical processing unit (shown as dotted lines). figure 1A pretreatment unit for removal of bulk solids or free oil is not shown, which may be required depending on the concentration of bulk solids and oil in the wastewater to be treated. Well known equipment such as grates, strainers and oil coalescers can be used to accomplish this task. The pretreatment unit may also be a mechanical device for reducing the size of bulk solids such as a grinder.

[0032] WETT units that may be involved in wastewater purification processes are listed below as well as figure 1 middle. In a preferred embodiment, the process consists of a series of 4 electrochemical units:

[0033] 1. Electrocoagulation (EC)

[0034] 2. Electric flotation (EF)

[0035] 3. Electrolytic Oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com