Sub transplanting mechanism of transplanter for female parent transplant in hybrid rice seed production

A technology of rice transplanter and hybrid rice, which is applied in the field of transplanting mechanism of rice transplanter, can solve the problems of not meeting the requirements of hybrid rice seed production, high labor intensity, high production cost, etc., achieve unstable seed quality, reduce labor intensity, solve The effect of labor shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

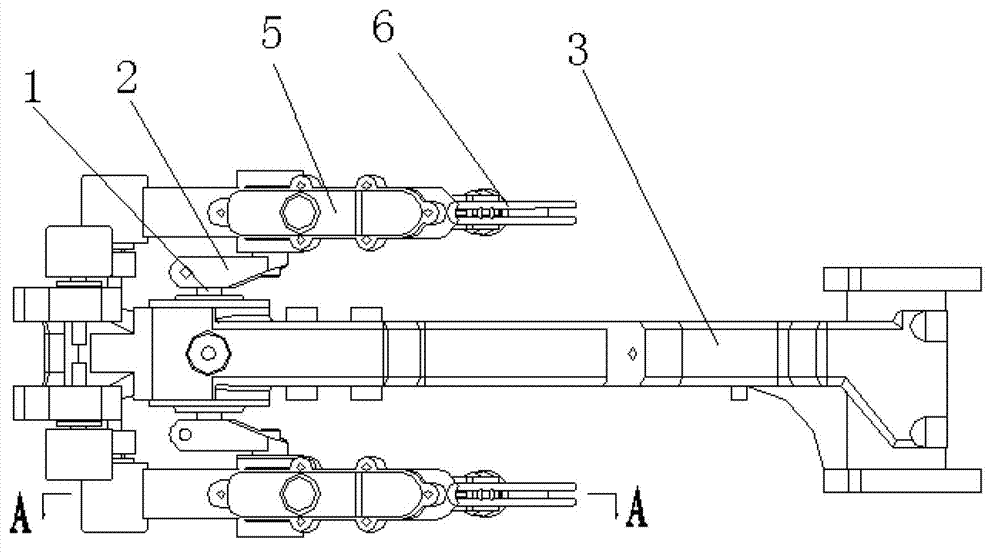

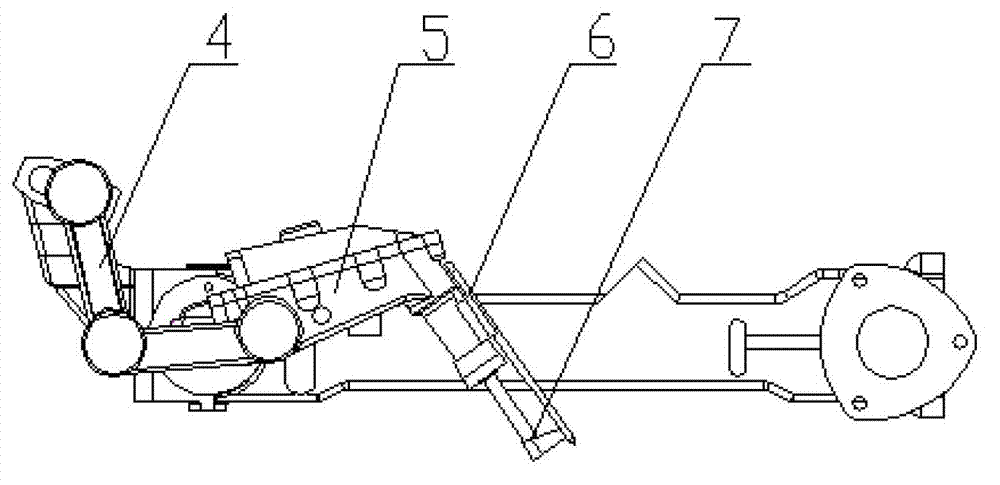

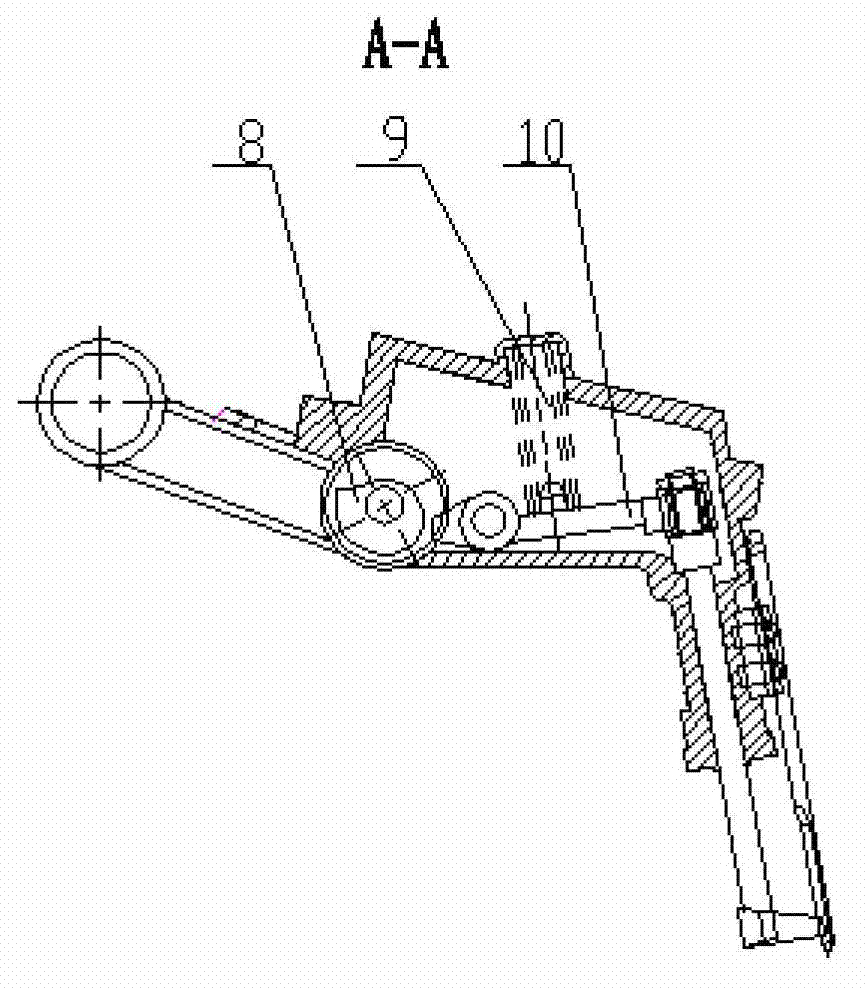

[0018] Refer to the attached drawings, a seedling transplanting mechanism for transplanting hybrid rice seed production female parents, including a support arm 3, a sprocket shaft 1, a planting arm 5, a crank 2, a rocker 4, a seedling claw 6, and a cam 8 , Fork 10, seedling pusher 7, the front end of the support arm 3 is provided with a sprocket shaft 1, two ends of the sprocket shaft 1 are respectively fixedly installed with a crank 2, the end of the crank 2 is fixedly installed with a planting arm 5, the rear end of the planting arm 5 Connected to the rocker 4, the rocker 4 is rotatably mounted on a bracket on the front end of the support arm 3. The planting arm 5 is equipped with a seedling claw 6 and a seedling pusher 7, which is located in the middle of the seedling claw 6, and The cam 8 and the shift fork 10 are driven. The cam 8 and the shift fork 10 are installed in the planting arm 5 in cooperation with each other. The planting arm 5 above the shift fork 10 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com