Air circuit system for portable respirator

A portable and ventilator technology, applied in the direction of respirators, etc., can solve the problems of complex composition of the gas circuit system, complex parameter settings, and large space occupied by the whole machine, so as to achieve simple composition of the gas circuit system, reduce setting time, and be convenient to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] At first, the portable ventilator of specific embodiment of the present invention is described:

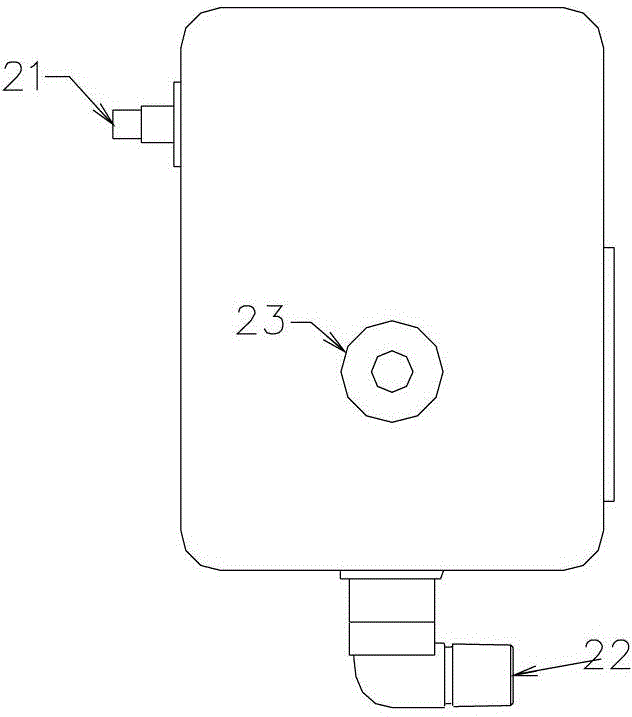

[0022] The portable ventilator has an external structure such as figure 2 As shown, only one air source input port 21 is connected to the oxygen cylinder, and the ventilator output port 22 is connected to the user through the patient breathing valve. The portable ventilator is provided with a linkage adjustment knob 23 for linkage control of minute ventilation volume and respiratory rate.

[0023] Second, the portable ventilator gas circuit system of the specific embodiment of the present invention is described:

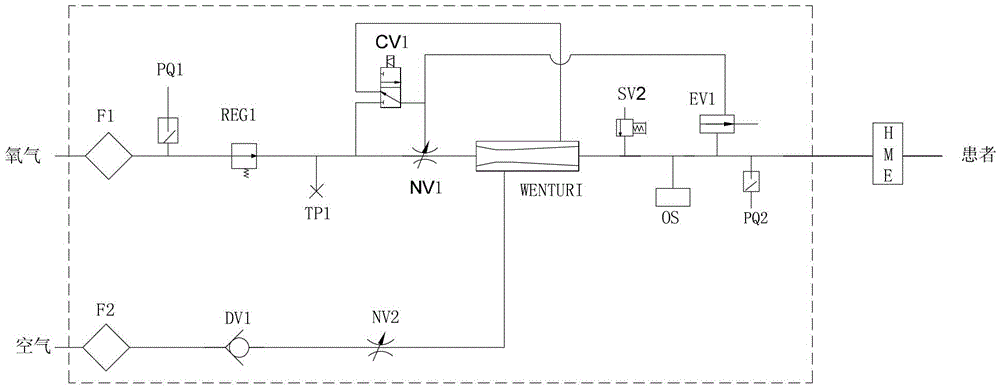

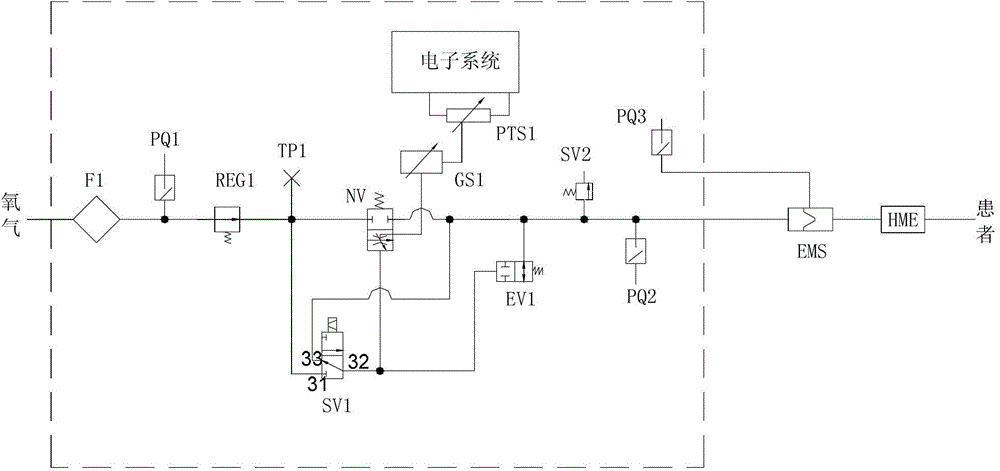

[0024] The gas system, the structure is as follows image 3 As shown, it includes the gas circuit communication pipeline connected between the output port 22 of the ventilator and the only gas source input port 21 and the pressure reducing valve REG1 and the flow regulating valve NV connected from the inlet to the outlet gas circuit; the system also includes T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com