Automatic positioning flame detection system for three-dimensional space

An automatic positioning and flame detection technology, which is applied in the field of flame detection systems, can solve the problems that the spraying device cannot realize fixed-point fire fighting, the height of the water spraying device is limited, and the pipe network of the water spraying device is complex, etc., to solve the problem of large space Fire monitoring problems, superior cost performance, and loss reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

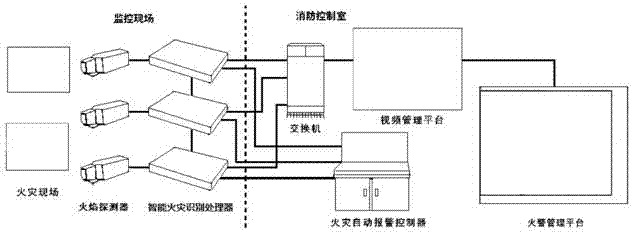

[0047] Such as figure 1 As shown, the system includes: a front-end monitoring unit connected to the fire scene, a control center connected to the front-end monitoring unit, and a fire linkage unit connected to the control center.

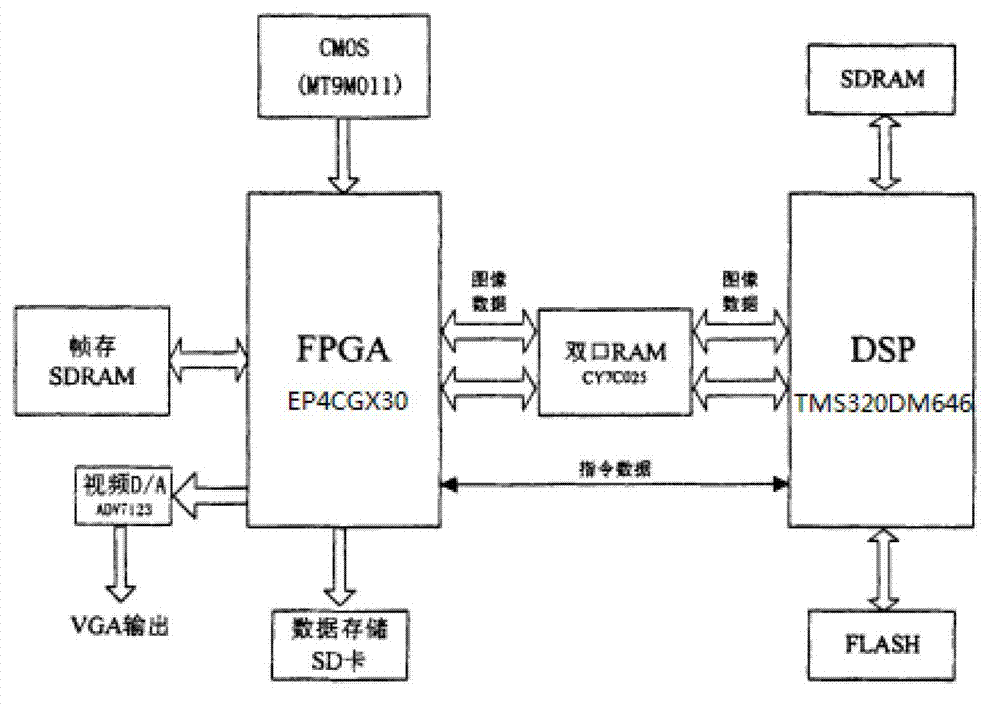

[0048] Among them, the front-end detection unit adopts a high-resolution infrared CCD image flame detector and an intelligent fire identification processor. The high-resolution infrared CCD image flame detector includes a large field of view lens, a CMOS image sensor and a large-scale field programmable Logic Array FPGA.

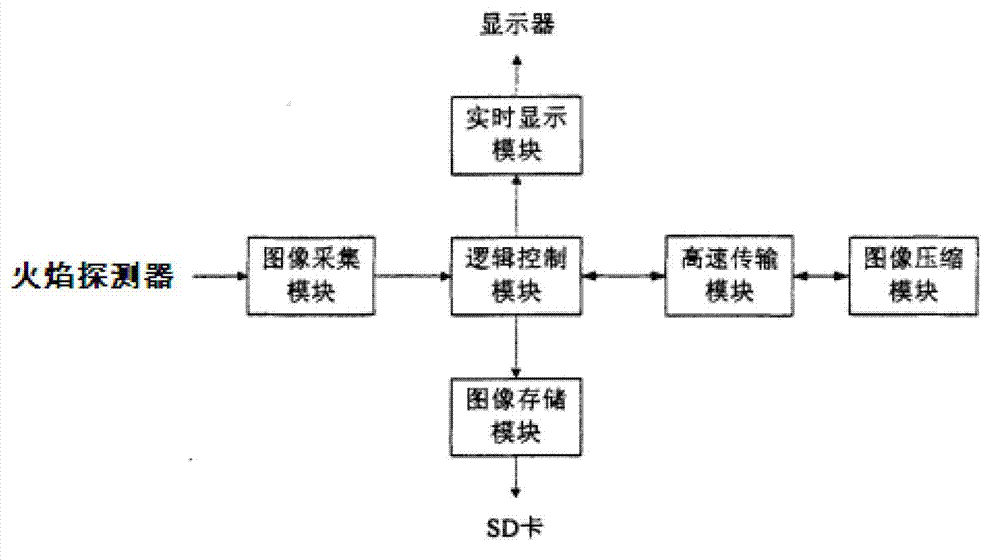

[0049] Such as figure 2 As shown, in the specific embodiment, the intelligent fire recognition processor includes a logic control module, and an image acquisition module, a real-time display module, an image storage module and a high-speed transmission module respectively connected to the logic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com