Stone rolling pulverizing mill

A pulverizer and stone grinding technology, applied in grain processing and other directions, can solve the problems of not satisfying people, traditional stone grinding work efficiency is low, and it is difficult to achieve quality indicators, etc., to achieve a wide range of applications, hard texture, good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

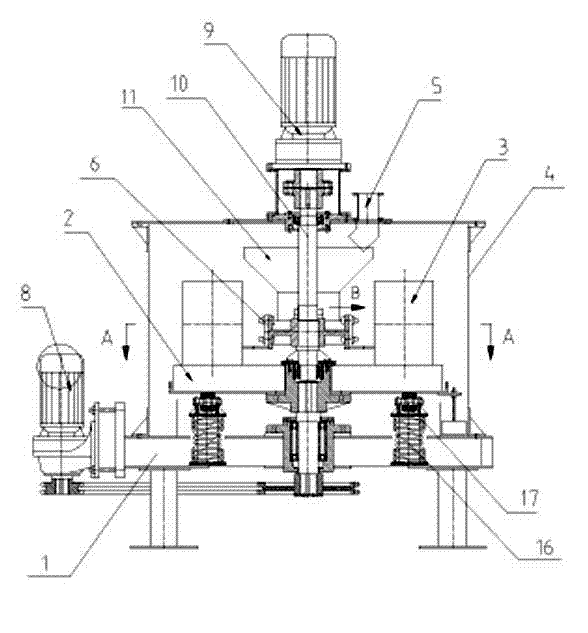

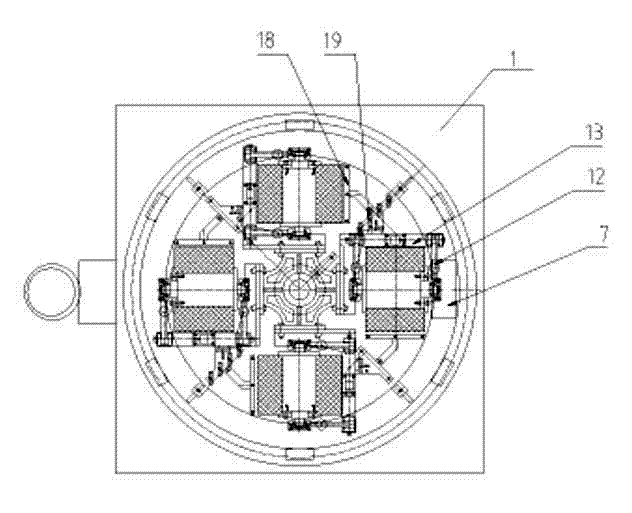

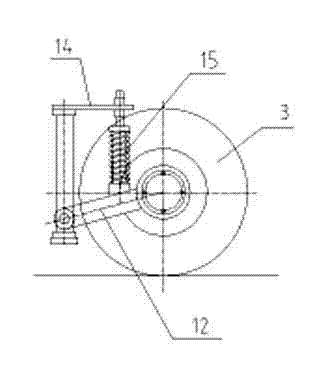

[0018] Such as figure 1 , 2 , 3, the stone mill powder machine of the present invention includes a stone mill disc 2 placed on the base 1 and a stone mill roller 3 that rotates around the working surface of the stone mill disc, and the base 1 is provided with a closed Type cylinder 4, the cylinder 4 covers the stone grinding disc 2 and the stone grinding roller 3 to ensure the cleanliness and sanitation of the grinding materials; the upper part of the cylinder 4 is provided with a feed port 5, corresponding to the feed port The upper part of the barrel at position 5 is provided with a material collection bucket 11. The outlet position of the material collection bucket 11 corresponds to the working area of the stone grinding disc 2. The two-stage feeding device can ensure that the material accurately falls into the grinding area on the grinding disc; The four stone grinding rollers 3 evenly distributed on the working surface of the stone grinding disc 2 are connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com