Kitchen waste pretreatment system and sorting method therefor

A technology for pretreatment and kitchen waste, applied in the field of environmental protection and renewable energy systems, can solve the problems of strong odor, complex components, and many components, and achieve the effect of eliminating odorous gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

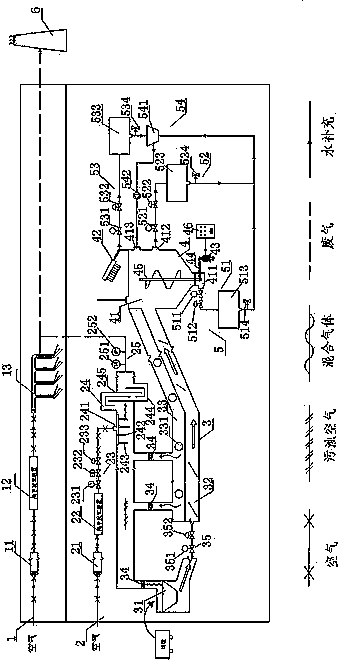

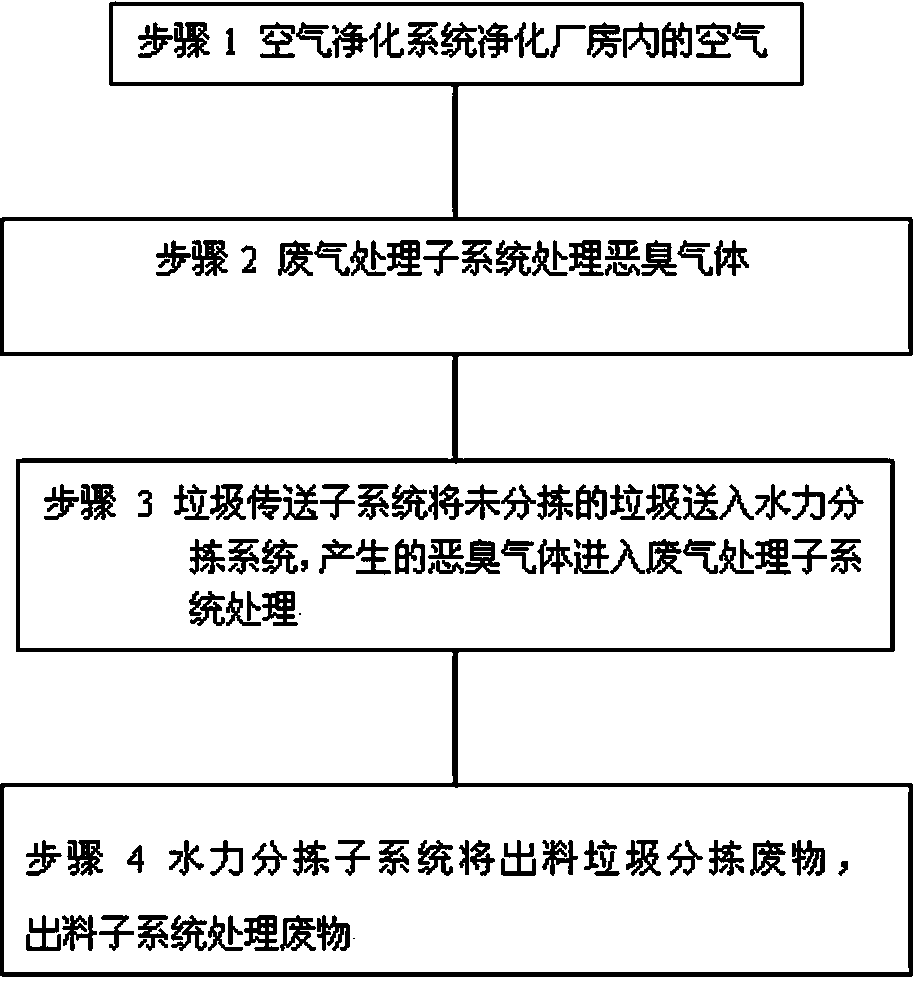

[0086] Combine below Figure 1~Figure 6 A food waste pre-treatment system and its sorting method of the present invention will be further elaborated, and a preferred embodiment of the present invention will be described in detail.

[0087] Such as figure 1 As shown, a food waste pretreatment system includes an air purification subsystem 1 , an exhaust gas treatment subsystem 2 , a garbage conveying subsystem 3 , a hydraulic sorting subsystem 4 and a material discharge subsystem 5 . The air purification subsystem 1 is set on the top of the factory building, and the waste gas treatment subsystem 2, the garbage conveying subsystem 3, the hydraulic sorting subsystem 4 and the material discharge subsystem 5 are set under the air purification subsystem 1 and connected by pipelines.

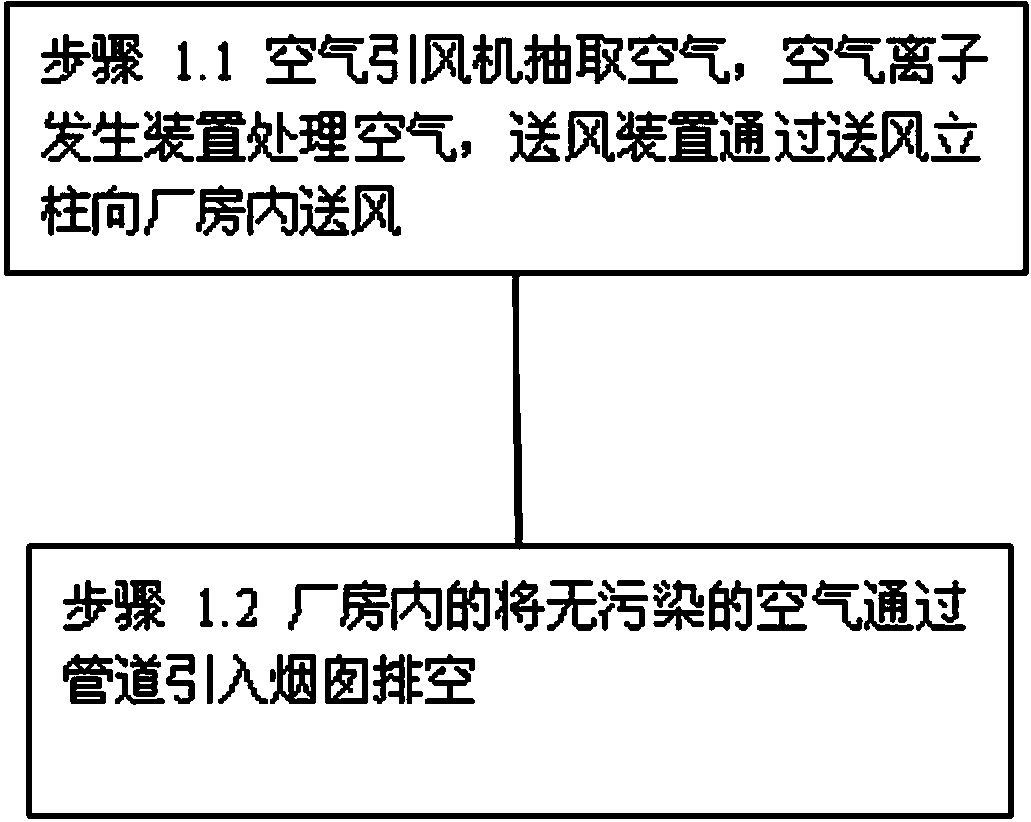

[0088] The air purification subsystem 1 comprises an air induced fan 11, an air ion generator 12, and an air supply device 13, and the air induced fan 11, the air ion generator 12, and the air supply d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com