Polishing machine of steel belt edges

A grinding machine and steel belt technology, applied in machine tools, grinding machines, grinding/polishing equipment suitable for grinding workpiece edges, etc., can solve the problem of reduced machine reliability, high use and manufacturing costs, and hysteresis of power consumption, etc. problem, to achieve the effect of precise control of grinding amount, convenient and reliable use, and high grinding uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

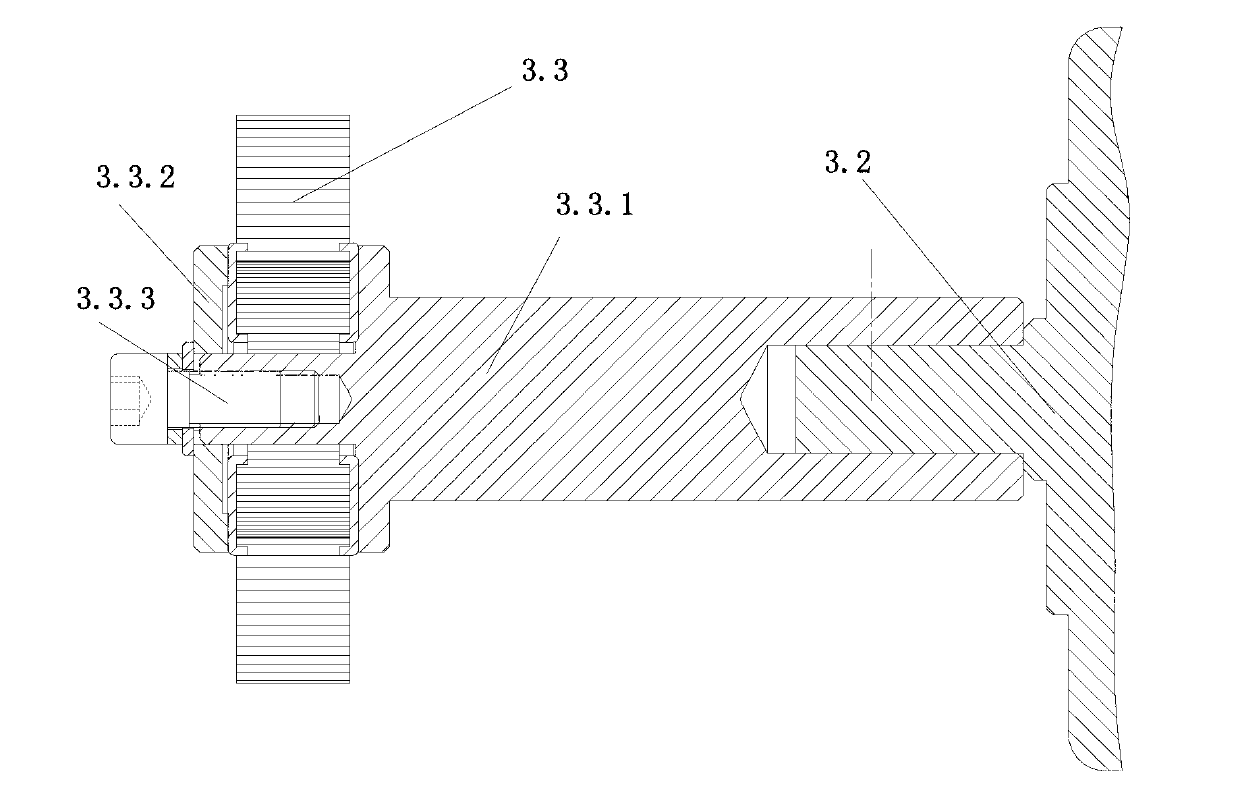

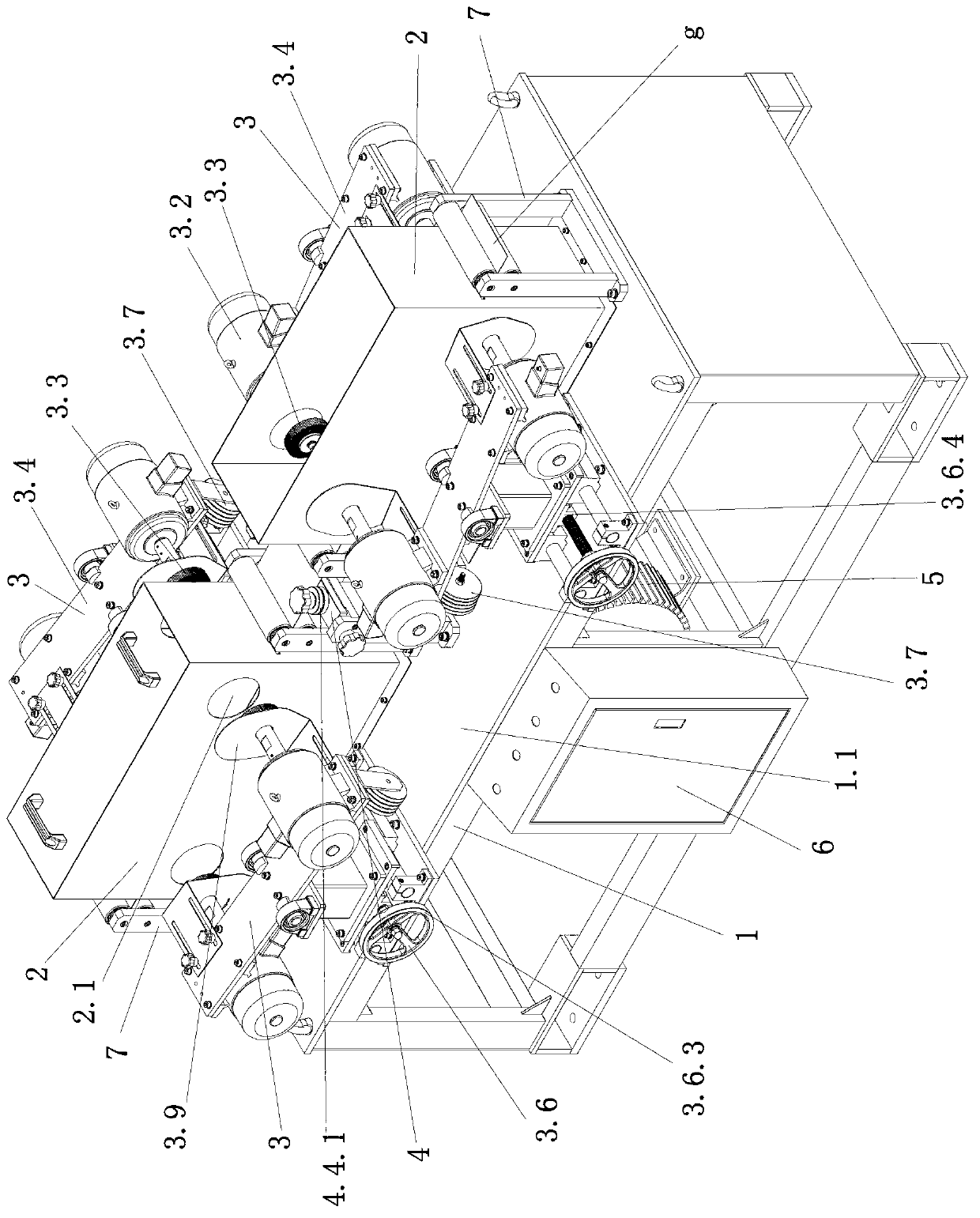

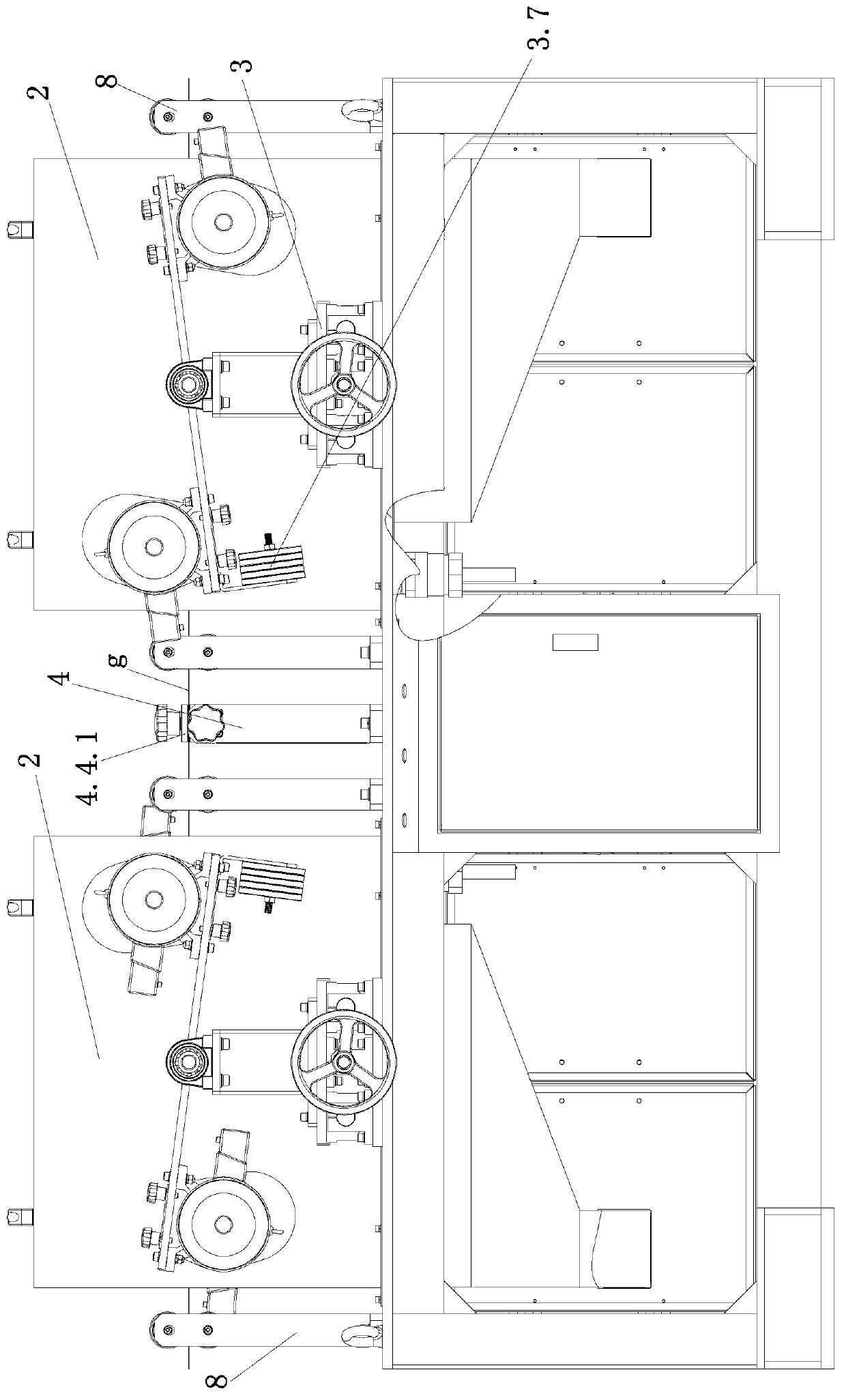

[0019] like figure 1 , figure 2 , image 3 and Figure 4 Shown, the present invention comprises frame 1, grinding ash collecting device, control cabinet 6, is fixed on the mounting platform 1.1 of the upper end of frame 1 and is provided with two polishing boxes 2 along the moving direction of steel belt; The main body of the grinding box surrounded by four side walls, the horizontal cross-section is rectangular, and the cover of the grinding box is located at the upper end of the main body of the grinding box; 1.1 Fixed connection, simple structure, convenient manufacture and installation; a steel belt passing hole for the steel belt to be polished is provided on the left and right side walls of each grinding box 2, and the installation of the front and rear sides of each grinding box 2 Each plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com