Automatic die filling fixture for IMD sheet material

A technology of jigs and sheets, applied in the direction of coating, etc., can solve the problems of low production efficiency, many operators, production chaos, etc., and achieve the effect of saving labor costs and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

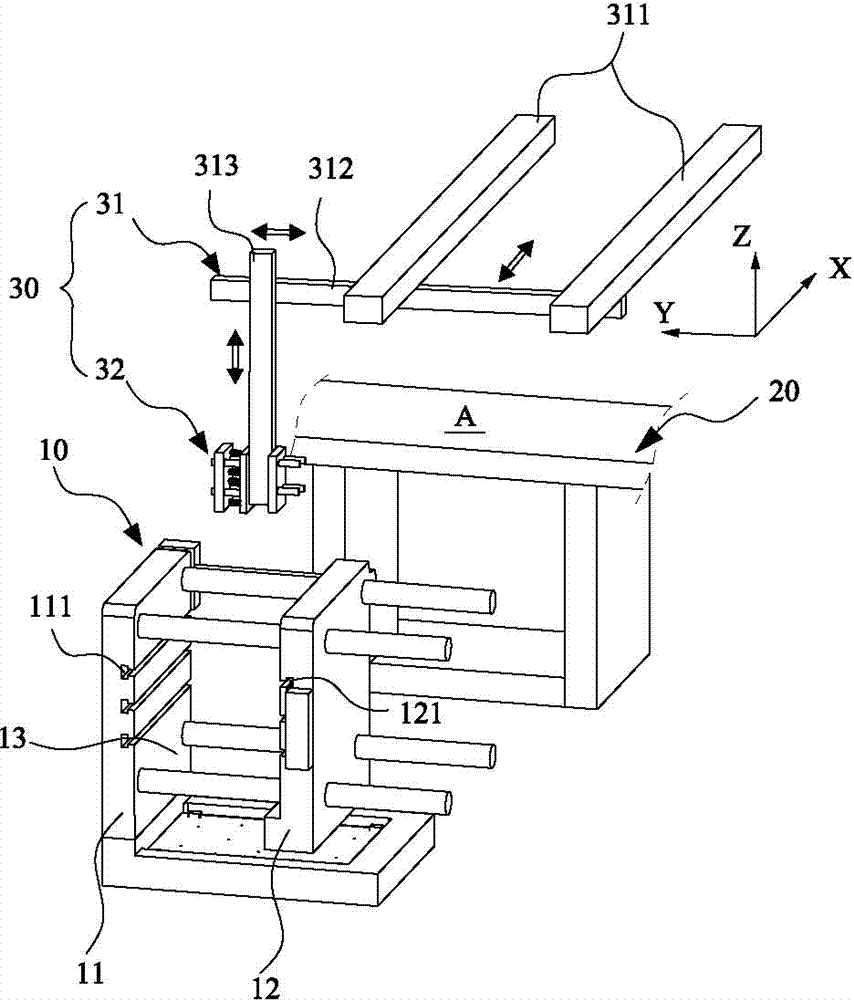

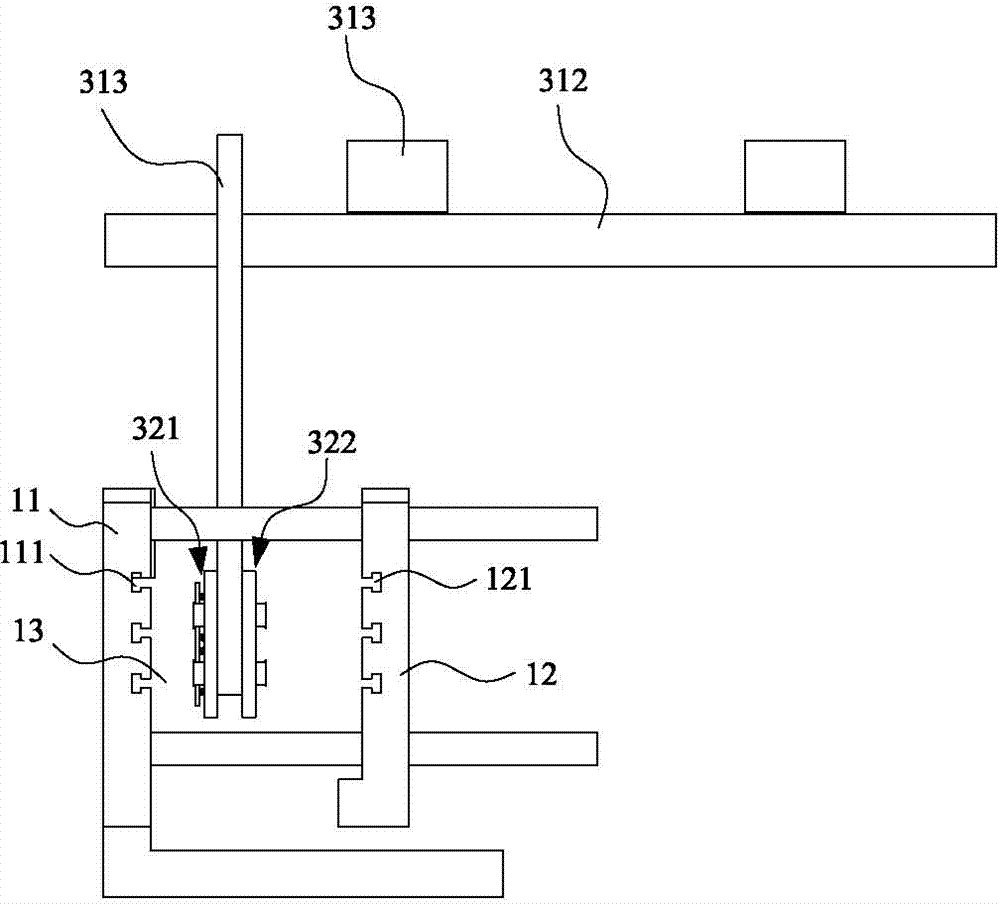

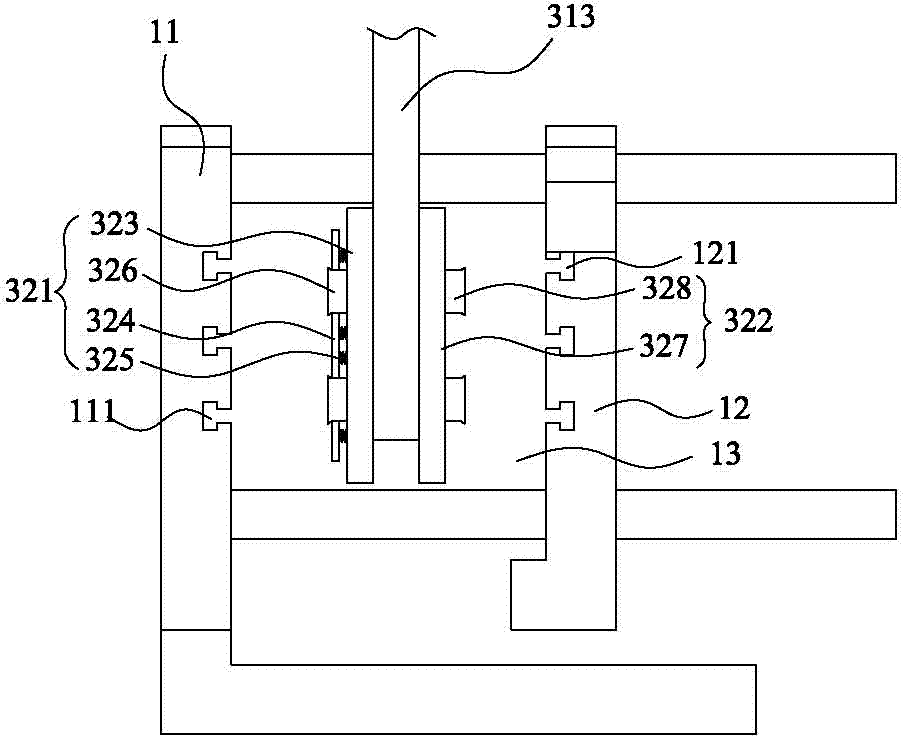

[0032] Please refer to Figure 1 to Figure 3 Shown, it has shown the concrete structure of preferred embodiment of the present invention, comprises IMD injection mold 10, feed fixture 20 and manipulator 30, and this manipulator 30 is used for IMD material part is automatically packed in IMD injection mold 10, And at the same time, the formed IMD sheet is taken out from the IMD injection mold 10 and placed on the feeding jig 20 .

[0033] Wherein, the IMD injection mold 10 comprises a fixed platen 11 and a movable platen 12, the fixed platen 11 and the movable platen 12 are vertically arranged, a mold cavity 13 is formed between the two, and the movable platen 12 is provided with a first mold The cavity 111 and the fixed template 11 are correspondingly provided with a second cavity 121, and the first cavity 111 and the second cavity 121 are facing each other on the left and right. The forming principle of the IMD injection mold 10 is as follows: by automatically feeding the IM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com