Integrated double-cross arm suspension wheel side electric driving system for steering wheel

An electric drive system, double wishbone technology, applied in the steering mechanism, steering rod, brake, etc., can solve the problems of increasing mass, affecting the grounding of the wheels and the ride comfort of the body, achieving low mass, sensitive steering response, and high integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

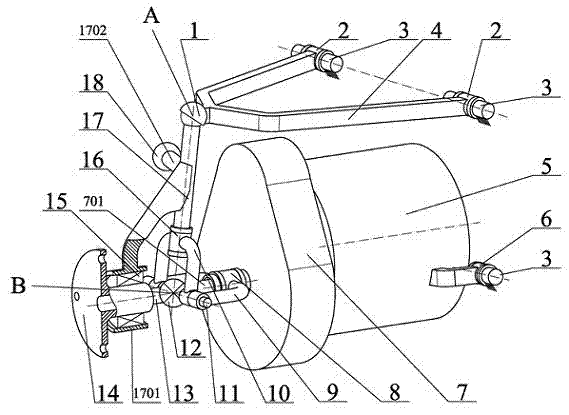

[0029] Attached below figure 1 The present invention is further described.

[0030] Such as figure 1 As shown, the present invention provides an integrated double-wishbone suspension wheel side electric drive system for steering wheels, including a first spherical joint 1, a first elastic hinge 2, a vehicle frame 3, an upper wishbone 4, and a motor 5. The second elastic hinge 6, the reduction box 7, the first rotating hinge 8, the lower cross arm connecting rod 9, the steering knuckle connecting rod 10, the second rotating hinge 11, the universal joint 12, the half shaft 13, the hub 14, the hub Bearing 15, third rotating hinge 16, steering knuckle 17, second ball joint 18; wherein,

[0031] The casing of the motor 5 is fixedly connected with the casing of the reduction box 7, and is supported on the frame 3 by two second elastic hinges 6 (only one is shown in the figure), and the hinge points between the two second elastic hinges 6 are The connecting line constitutes the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com