Auxiliary side wall, high-speed motor train unit body and high-speed motor train unit

A technology for auxiliary side walls and car bodies, which is applied to railway car bodies, parts of railway car bodies, transportation and packaging, etc. It can solve the problems of poor sound insulation, heat insulation and cold resistance, simplicity, and excessive structure of auxiliary side walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

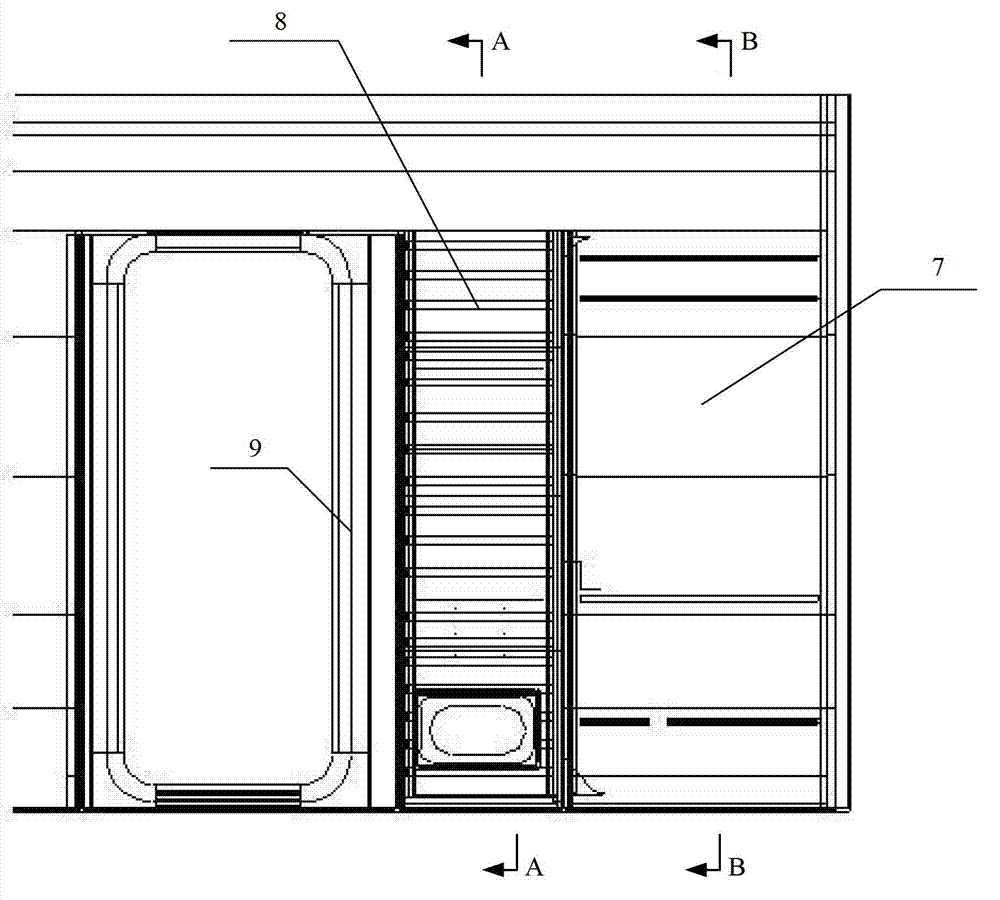

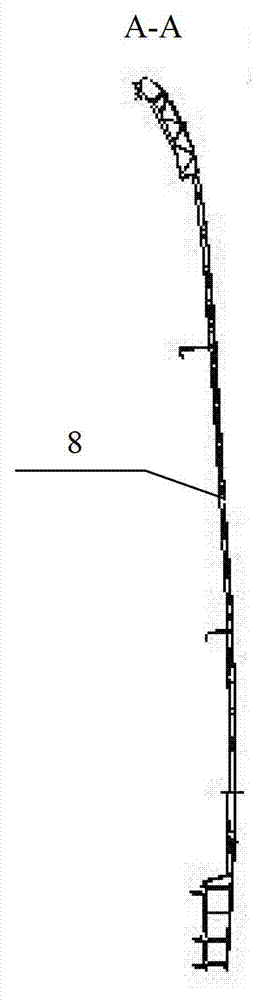

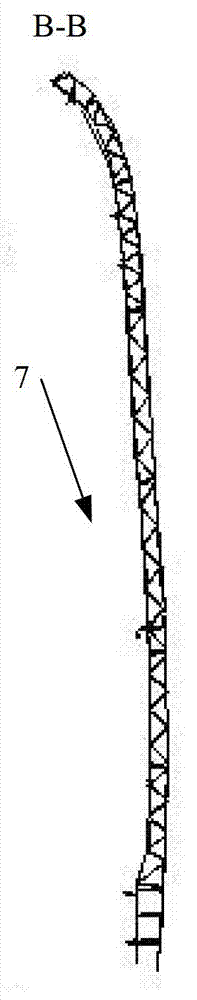

[0036] Figure 2a It is a schematic front view of the structure of the auxiliary side wall provided by Embodiment 1 of the present invention, Figure 2b for Figure 2a left view diagram of .

[0037] Embodiment 1 of the present invention provides an auxiliary side wall, wherein the auxiliary side wall 6 includes a plurality of hollow profiles 1 , and the plurality of hollow profiles 1 are pieced together and welded to form the auxiliary side wall 6 .

[0038] Hollow profiles can play a good role in sound insulation, heat insulation and cold protection because of the air in the hollow part. Here, the hollow profile can be made of aluminum alloy.

[0039] see Figure 2b , here, specifically, each hollow profile 1 includes two base plates 11 and a rib plate 12 sandwiched between the two base plates 11, the two base plates 11 and the rib plate 12 form a closed Hollow structure.

[0040] The hollow profile in the above implementation manner may have various specific structura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com