Disturbing device for conveying materials, pneumatic conveying device and material conveying method

A pneumatic conveying and material technology, applied in the direction of conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problem that the uniformity of falling of anti-blocking materials cannot be solved at the same time, and achieve the effect of preventing accumulation and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

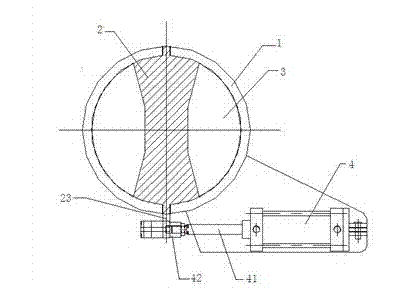

[0040] Such as image 3 and Figure 4 As shown, the disturbance device for material transportation provided by this embodiment includes a housing 1 having a housing inlet and a housing outlet; it also includes a disturbance component 2 installed in the housing Inside the body 1, a material circulation channel 3 is formed with the inner wall of the housing 1; the driving mechanism is connected with the disturbance component 2, and the flow cross-sectional area of the material circulation channel 3 is changed by controlling the disturbance component 2, thereby changing The falling speed of the material, thereby preventing the material from caking and clogging.

[0041] It should be noted that, in the present invention, there are various ways to change the flow cross-sectional area of the material flow channel 3 by controlling the disturbing member 2, which can be a rotation method or a parallel movement method. The ways in which the disturbance member 2 changes the flow cr...

Embodiment 2

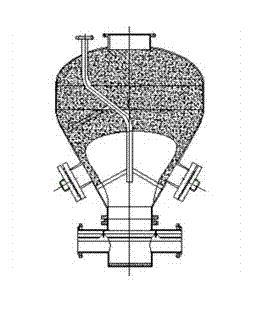

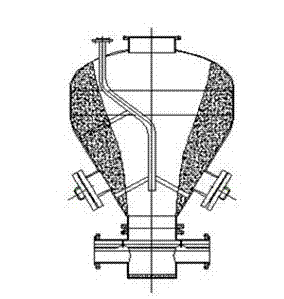

[0051] Such as Figure 8 As shown, the present embodiment provides a pneumatic conveying device, comprising a conveying tank 6, having a discharge port arranged at the bottom of the conveying tank 6, a feed valve arranged on the conveying tank 6, extending into the The air blowing device in the delivery tank 6, and the disturbance device arranged at the bottom of the delivery tank 6, the disturbance device includes a housing 1, and the housing 1 has a housing inlet and a housing outlet, so The feed port of the disturbance device communicates with the discharge port of the delivery tank 6, the mixer, the mixer has a mixer feed port and a mixer discharge port, and the mixer feed port is connected to the shell The body discharge port is connected; the disturbance device also includes a disturbance component 2, which is installed in the housing 1 and forms a material flow channel 3 with the inner wall of the housing 1; and a driving mechanism to drive the disturbance The componen...

Embodiment 3

[0064] This embodiment provides a method for conveying materials using the pneumatic conveying device described in Embodiment 2, including the following steps:

[0065] A. Open the blowing device to blow compressed air into the delivery tank 6;

[0066] B. Open the feed valve to transport the material into the delivery tank 6, and the material flows to the mixer 7 along the material circulation channel 3 under the action of compressed air and its own gravity;

[0067] C. When the pressure detection device detects that the pressure in the delivery tank 6 is less than the predetermined pressure, control the action of the disturbance device, so that the cross-sectional area of the material circulation channel 3 changes the falling speed of the material, preventing The material arches and clogs.

[0068] As a preferred implementation manner, in this embodiment, the cross-sectional area of the material circulation channel 3 is changed by changing the relative positional relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com