Multi-dielectric ceramic low-eradiation coated glass

A low-radiation coating, multi-media technology, applied in glass/slag layered products, chemical instruments and methods, layered products, etc., can solve the problems of acidity and reduce the service life of glass, and achieve long service life and low radiation. efficiency, high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

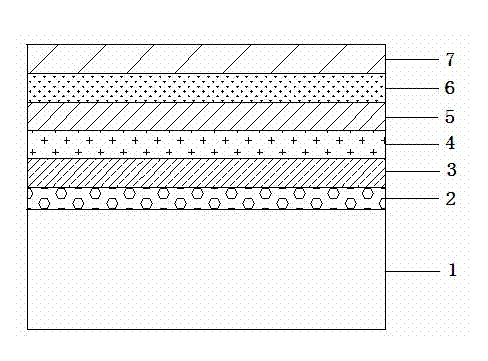

[0010] Such as figure 1 In the multi-media ceramic low-emissivity coated glass shown, titanium oxide layer 2, zinc-aluminum oxide ceramic layer I3, silver film layer 4, zinc-aluminum oxide ceramic layer II5, zinc-aluminum oxide Ceramic layer III6 and tin oxide layer 7.

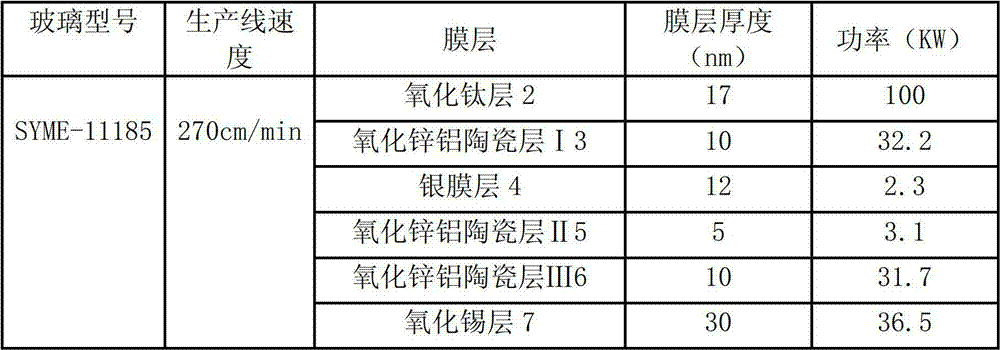

[0011] The production parameters of each film layer of the multi-media ceramic low-e coated glass are shown in the table below:

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com