Preparation method for polyoxyethylene mono-caprylic-capric acid glyceride

A technology of glyceryl caprylate and polyoxyethylene, which is applied in the field of synthesis of nonionic surfactants in organic chemistry, can solve the problems of large environmental pollution, dark color, troublesome process, etc., and achieve simple reaction equipment and no pollution , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

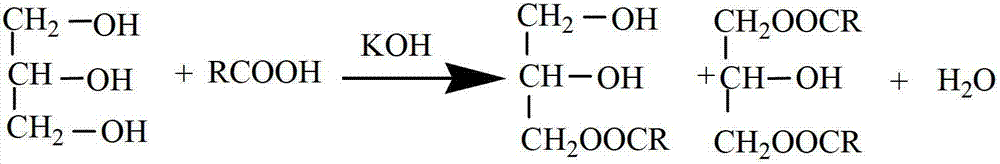

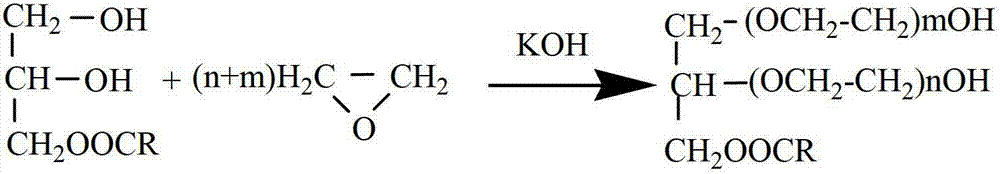

Method used

Image

Examples

Embodiment 1

[0015] 1) Esterification reaction: Add 644 grams of glycerin and 1036 grams of caprylic acid into a 2L flask by weight, add 0.336 grams of solid catalyst stannous chloride under stirring, slowly raise the temperature, and separate the esterification reaction in time under the condition of nitrogen flow The generated water was heated up to 180°C under the reaction conditions, kept warm for 3.0 hours, then cooled to 60°C, and discharged. The conversion rate of the acid was 99.9%.

[0016] 2) Purification of monocaprylic capric acid ester: use a rotary scraper thin film evaporator to collect about 700 grams of monocaprylic capric acid glycerides in light fractions at a temperature of 130 ° C and a pressure of 8 Pa, and the other fraction is dicaprylic capric acid glycerides by-product .

[0017] 3) Condensation reaction of ethylene oxide: Add 400 grams of monocaprylic capric acid glyceride into a 2L addition kettle, stir and add 7.6 grams of potassium hydroxide, replace with nitr...

Embodiment 2

[0020] 1) Esterification reaction: Add 644 grams of glycerin and 1085 grams of caprylic acid into a 2L flask by weight, add 0.5187 grams of solid catalyst stannous oxide under stirring, slowly raise the temperature, and separate out the esterification reaction in time under the condition of nitrogen flow. The water was heated up to 150°C under the reaction conditions, and kept for 6.0 hours, then cooled to 50°C and discharged, and the conversion rate of the acid was 99.8%.

[0021] 2) Purification of monocaprylic capric acid ester: use a rotary scraper film evaporator to collect about 750 grams of monocaprylic capric acid glycerides in light fractions at a temperature of 140 ° C and a pressure of 10 Pa, and the other fraction is dicaprylic capric acid glycerides by-product .

[0022] 3) Condensation reaction of ethylene oxide: add 400 grams of monocaprylic capric acid glyceride into a 2L addition kettle, stir and add 3.6 grams of sodium hydroxide, replace nitrogen three times ...

Embodiment 3

[0025] 1) Esterification reaction: Add 644 grams of glycerin and 1141 grams of caprylic acid in a 2L flask by weight, add 0.7140 grams of solid catalyst stannous chloride under stirring, slowly raise the temperature, and separate the esterification reaction in time under the condition of nitrogen flow The generated water was heated up to 160°C under the reaction conditions, kept warm for 5.0 hours, then cooled down to 70°C, and discharged. The conversion rate of the acid was 99.99%.

[0026] 2) Purification of monocaprylic acid ester: use a rotary scraper film evaporator to collect about 790 grams of monocaprylic acid glycerides in light fractions at a temperature of 135 ° C and a pressure of 12 Pa, and the other fraction is dicaprylic capric acid glycerides by-product .

[0027] 3) Ethylene oxide condensation reaction: Add 400 grams of monocaprylic capric acid glyceride into a 2L addition kettle, stir and add 2.4 grams of sodium hydroxide, replace nitrogen three times and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com