Adjusting device and method for injection flow rate of evaporative cooling tower during dry converter dedusting

A converter dry dust removal, evaporative cooling technology, applied in the direction of manufacturing converters, improving process efficiency, improving energy efficiency, etc., can solve problems such as reducing the service life of equipment, reducing the effect of electric field dust removal, and valve actions cannot keep up with changes. Achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

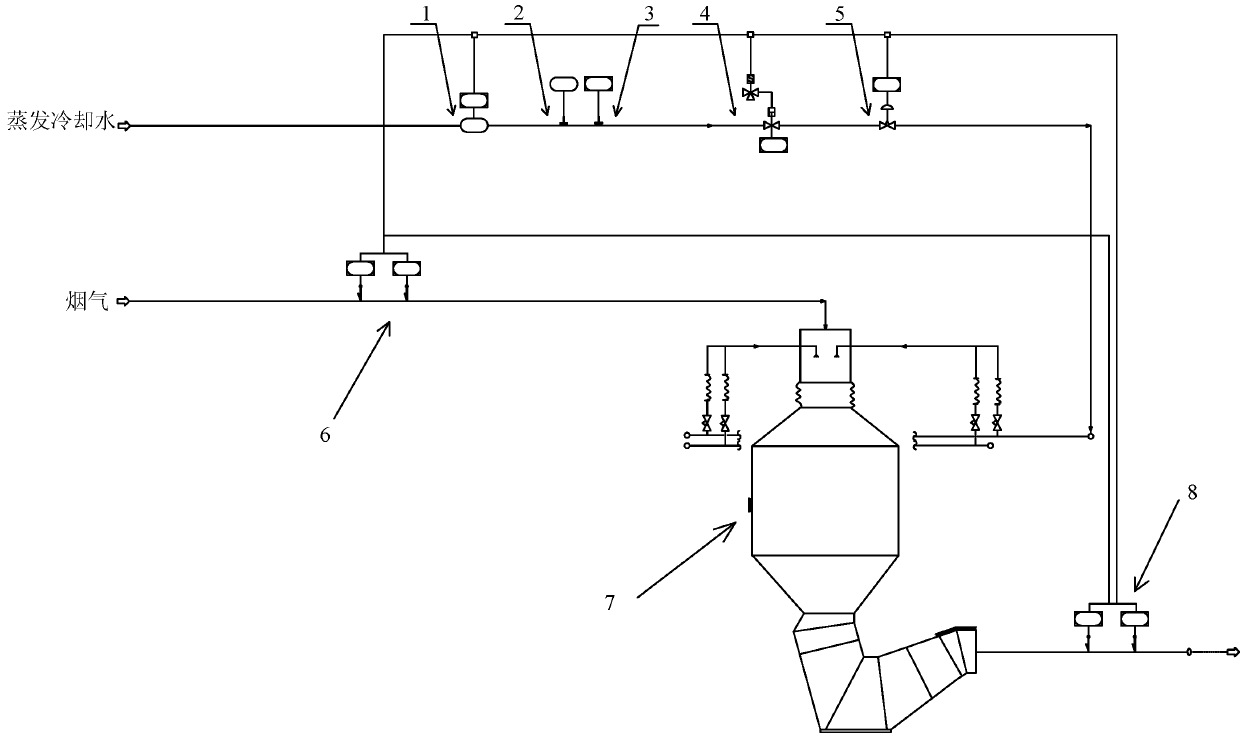

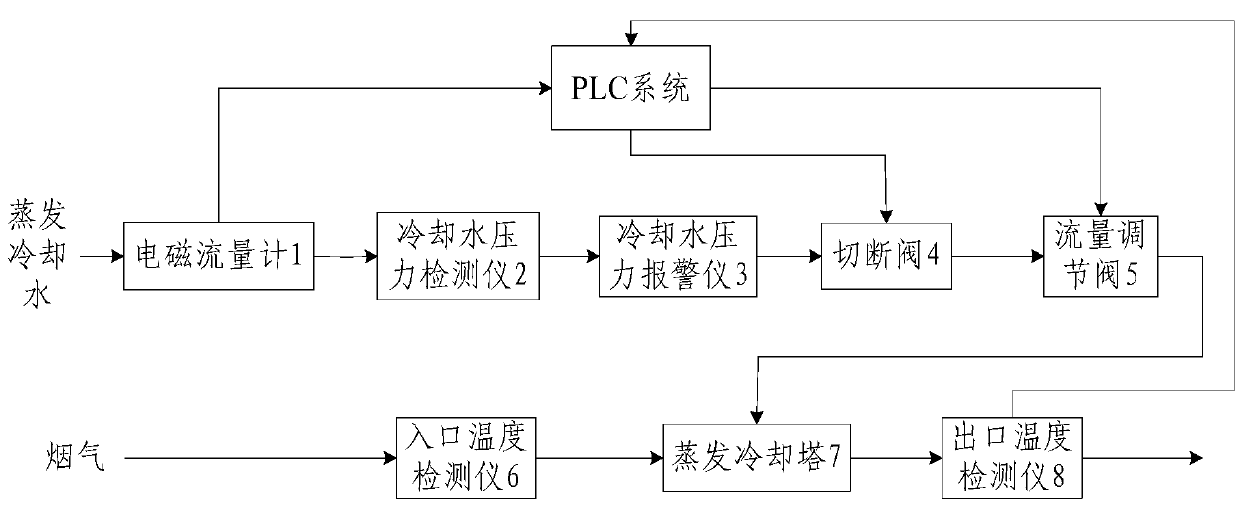

[0015] Such as figure 1 As shown, the converter dry dedusting evaporative cooling tower spray water adjustment device of the present invention comprises an evaporative cooling tower 7, and the cooling tower has two input ports and an output port, wherein one of the input ports is connected to the flue gas channel, and on the flue gas channel An inlet temperature detector 6 is provided, and the other input port is connected to the evaporative cooling water channel, and the evaporative cooling water channel is provided with an electromagnetic flowmeter 1, a cooling water pressure detector 2, a cooling water pressure alarm 3, a shut-off valve 4 and A flow regulating valve 5; the output port is connected to an outlet temperature detector 8.

[0016] The method for adjusting the amount of sprayed water in the converter dry dedusting evaporative cooling tower of the present invention is divided into two processes: at the initial stage of blowing, open-loop control of the opening of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com