Light beam shaping and cutting system for stage luminaire and stage luminaire

A cutting system and lighting technology, applied in the direction of optics, optical components, light source fixation, etc., can solve the problems of limited operating freedom of cutting components, difficult to cut components, fast cutting speed, complex structure, etc., to achieve convenient transportation and storage placement, Good cutting strobe effect, simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structure and working principle of the present invention will be described in detail below with reference to the accompanying drawings.

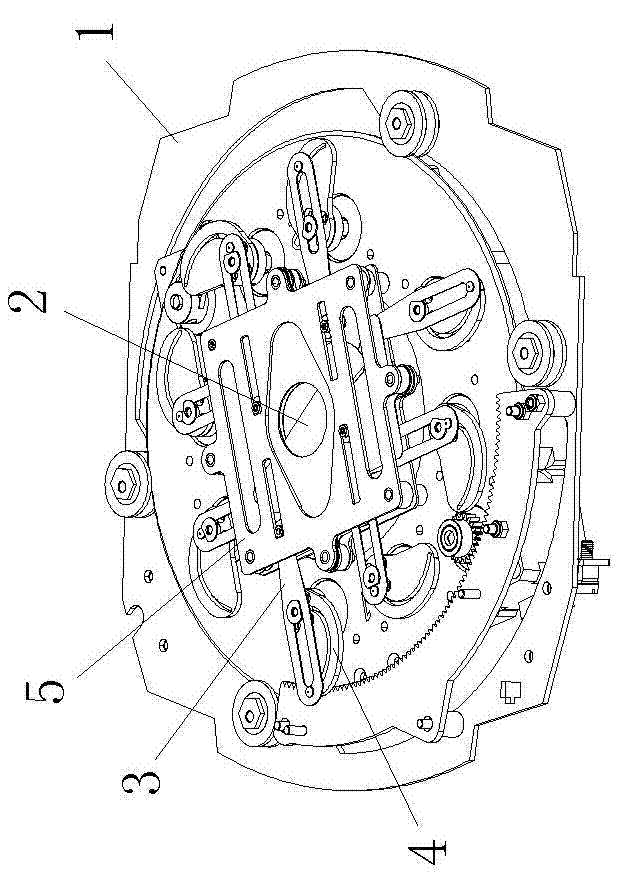

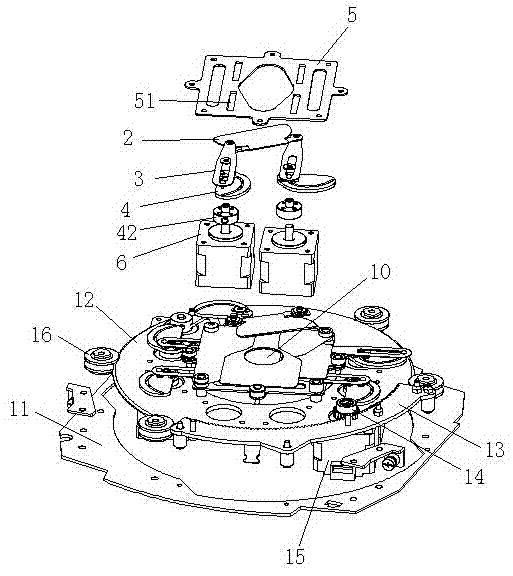

[0034] refer to Figure 1-3 As shown, the beam forming and cutting system for stage lamps and lanterns of the present invention includes:

[0035] The bracket 1 extends along the light beam direction of the stage lamp and is fixedly connected with the shell of the stage lamp;

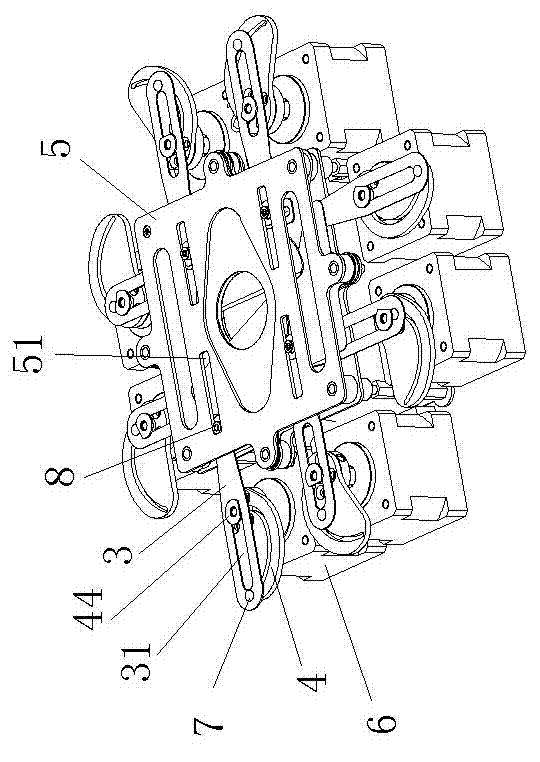

[0036] A cutting mechanism composed of four groups of cutting blades 2, each group of cutting blades is respectively arranged in a different plane perpendicular to the light beam and can move along the plane where it is located;

[0037] Four pairs of actuators, each pair of actuators are connected to a group of corresponding cutting blades 2; any one of the actuators includes a driving motor 6 and a transmission mechanism, and the driving motor 6 is fixed on the bracket 1.

[0038] Such as Figure 2 to Figure 5 As shown, any transmission mechanism inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com