Apparatus for charging raw material in sintering machine

A technology of raw materials and guide grooves, applied in the direction of furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of not being able to apply scrapers, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] Hereinafter, an embodiment of an apparatus for charging raw materials for sintering according to the present invention will be described in detail with reference to the drawings. In addition, the downstream side in the flow direction of the sintering raw material is defined as the front, and the upstream side is defined as the rear.

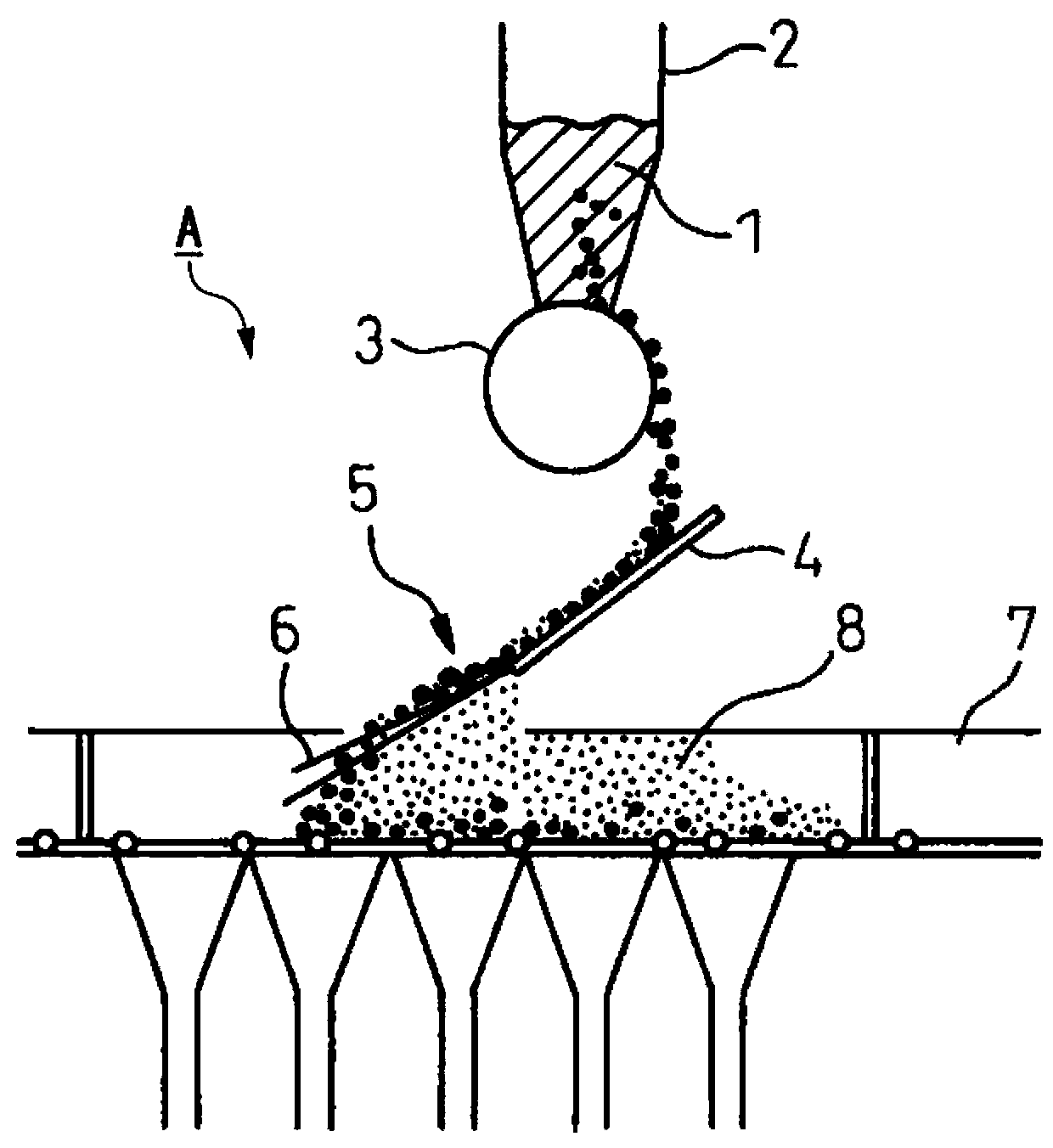

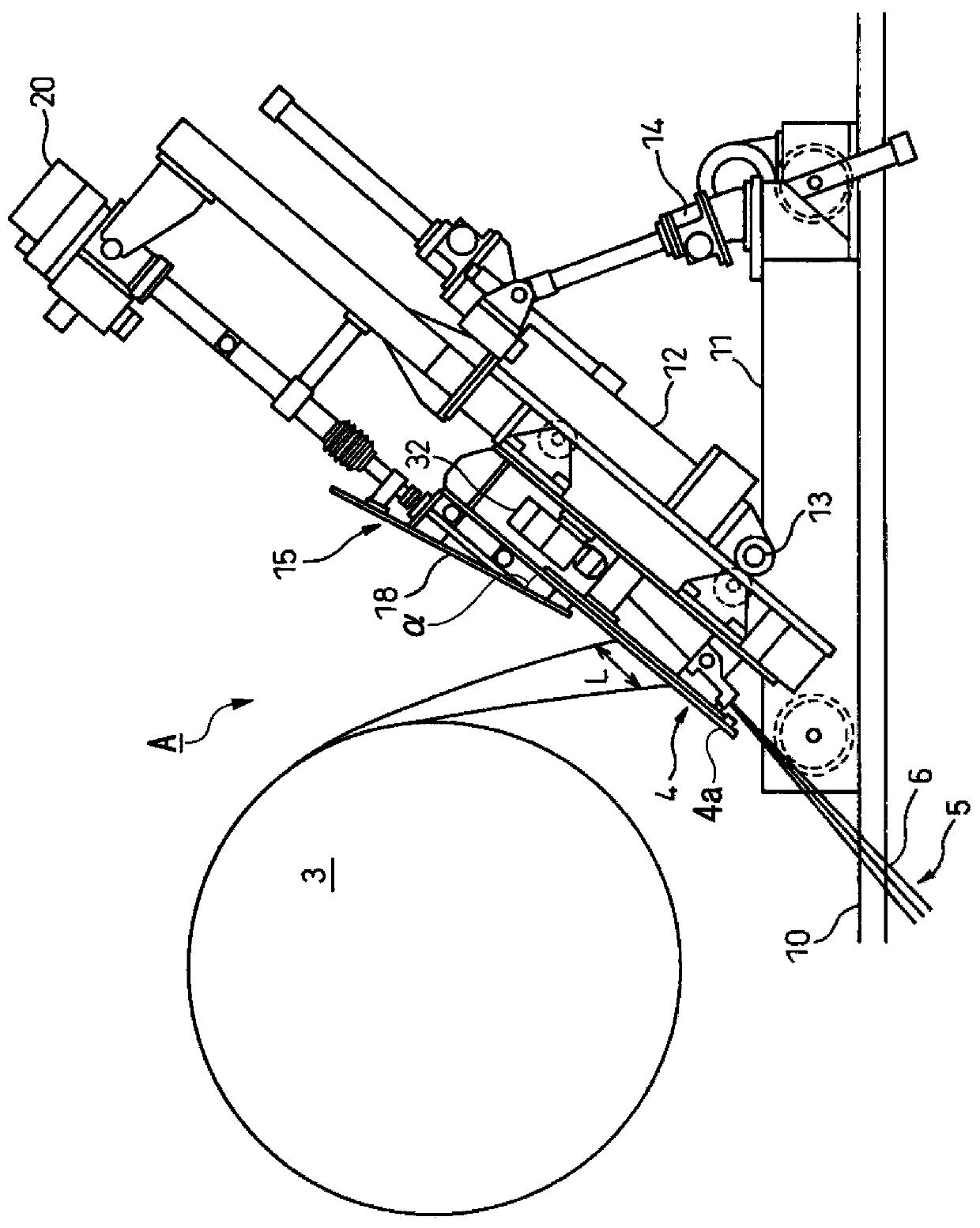

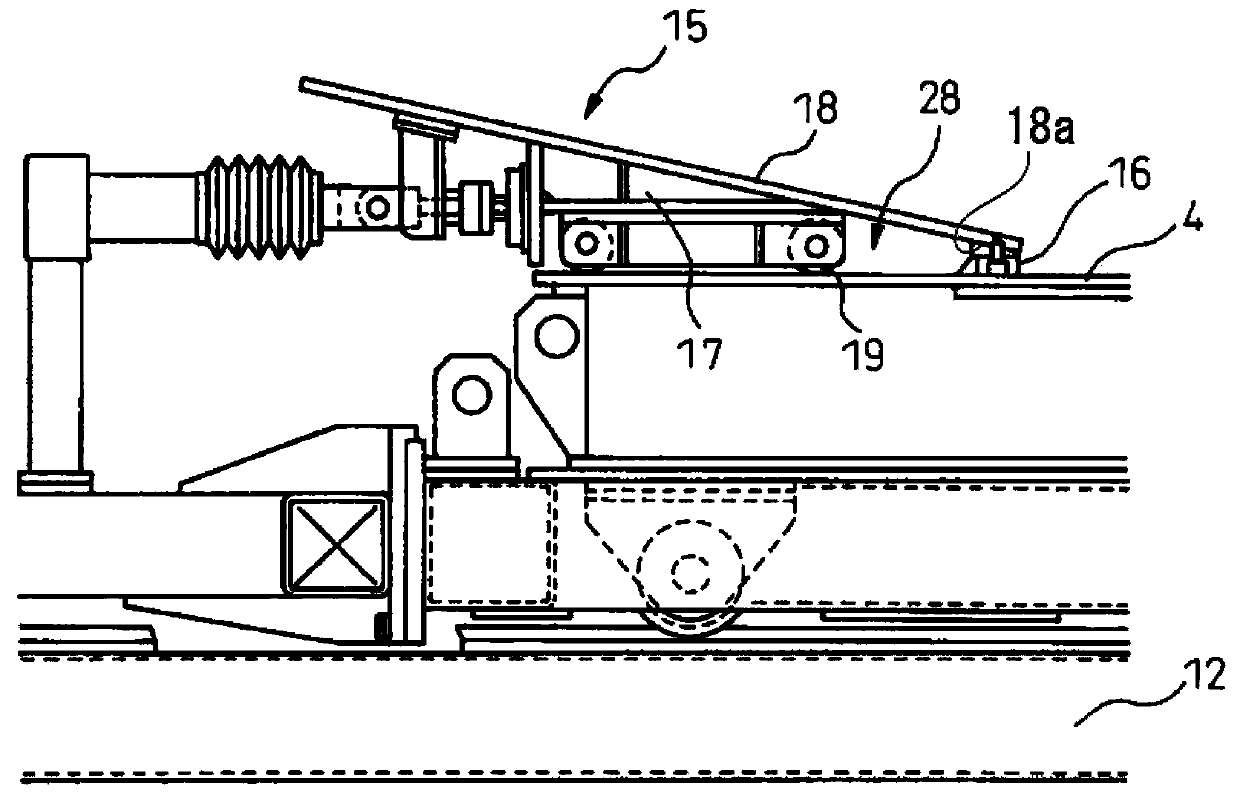

[0093] Such as figure 1 and figure 2 As shown, the loading device A for sintering raw materials is equipped with a guide groove 4 and a scraper 15 . The guide groove 4 is set between the barrel feeder 3 and the sintering trolley 7 of the sintering machine, and supplies (loads) the sintering raw materials taken out through the barrel feeder 3 onto the sintering trolley 7 . Such as figure 2 As shown, the guide trough 4 is mounted on a support trolley 11 that travels on a pair of rails 10 laid along the conveying direction of the sintering trolley 7 .

[0094] A tilt stand 12 capable of tilting the support guide groove 4 is attached to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com