Environment-friendly midsole shoes and manufacturing method thereof

A production method and an environment-friendly technology, which can be used in footwear, shoe soles, auxiliary devices for rope making, etc., can solve the problems of large size of rice straw, long rot time, and reduced soil, so as to reduce environmental pollution, facilitate mass production, Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

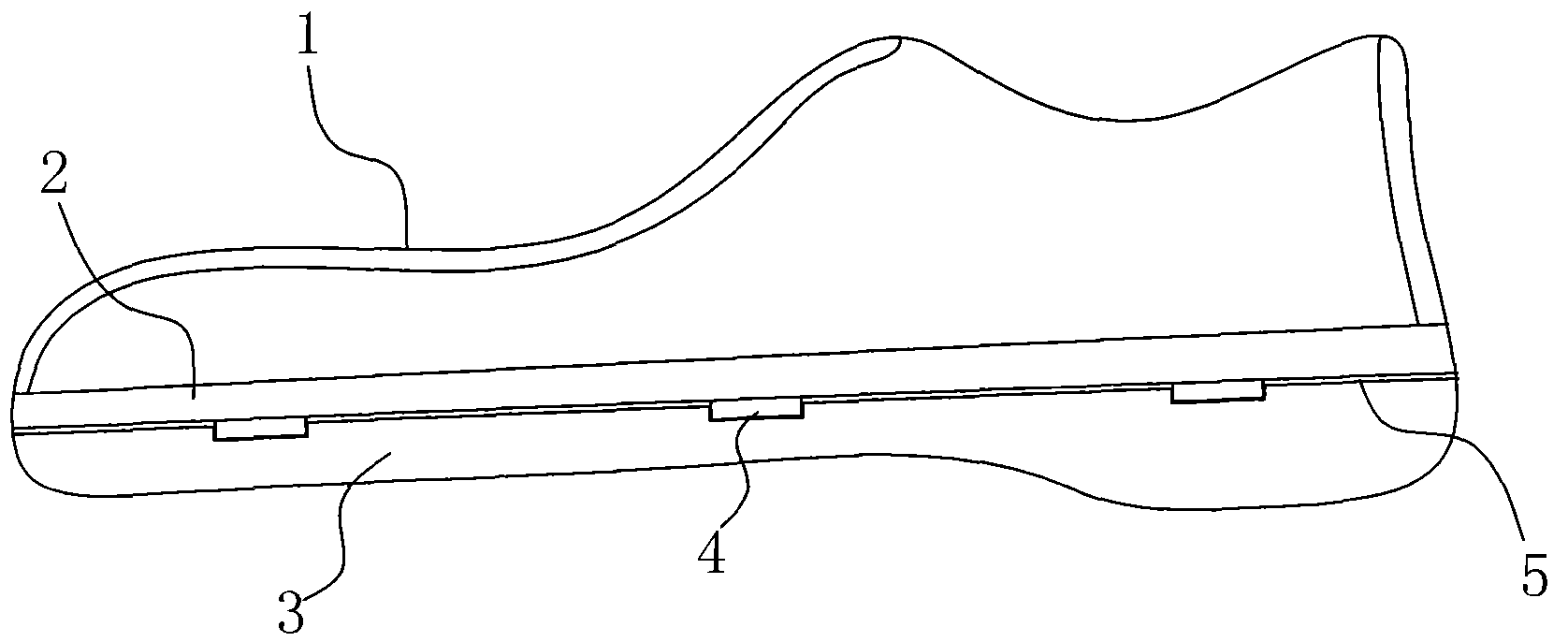

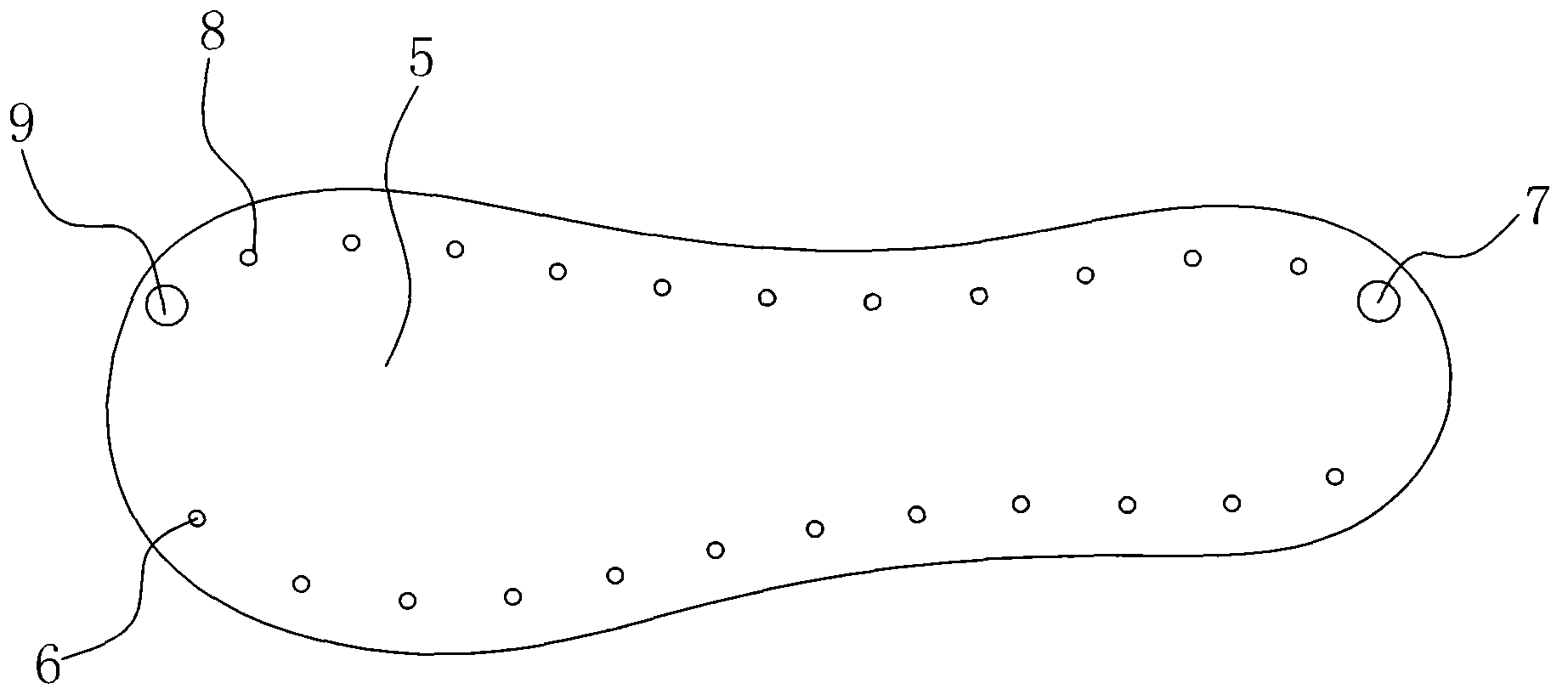

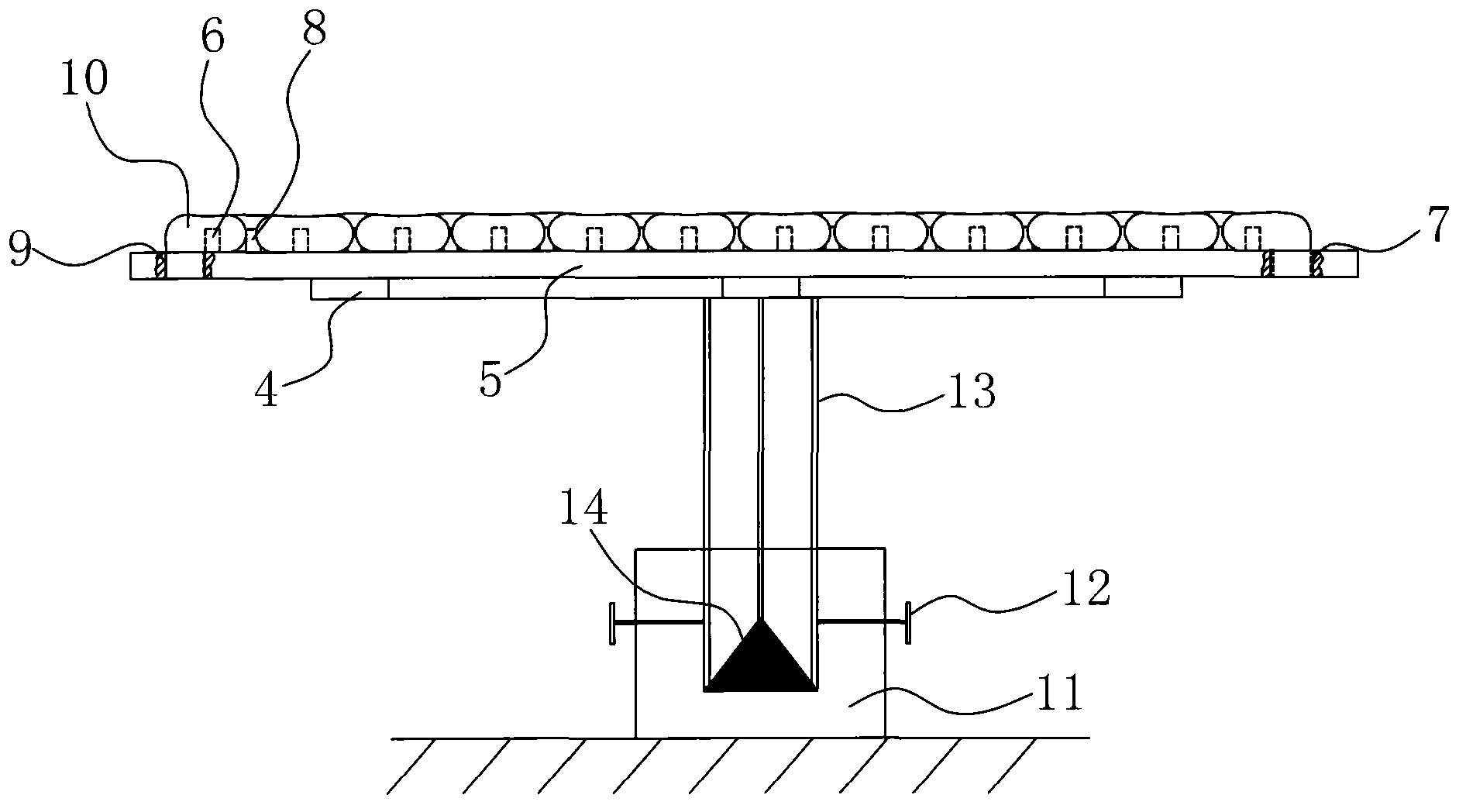

[0019] Combine now Figure 1-5 , the specific embodiment is described as follows taking the manufacturing method as an example.

[0020] Name and serial number in the figure: vamp 1, midsole 2, sole 3, first V-shaped block 4, foot plate 5, front end block 6, second reserved hole 7, rear end block 8, first reserved hole 9, Rice stalk rope 10, V-shaped groove block 11, ejector rod 12, connecting rod 13, V-shaped block 14, pre-twisted rope 15, feeding tank 16, front twisted rope clamp 17, rear twisted rope clamp 18 , Twisted rope tractor 19, hand wheel 20, shaping tractor 21, twisted rope traction sizing device 22, conveyor belt 23.

[0021] The manufacturing method of environment-friendly mid-sole shoes, the shoes include vamp 1, mid-sole 2, sole 3, one of the materials for mid-sole is straw rope, and its production process is as follows:

[0022] Clean the collected rice stalks from foreign objects, wash off the soil in the rice stalk cleaning tank, wash the muddy rice stalks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com