Once-fired color microcrystal brick and production process thereof

A production process and microcrystalline technology, which is applied in the field of once-fired colored microcrystalline bricks and its production process, can solve problems such as large application limitations, and achieve the effects of wide practicability, easy production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

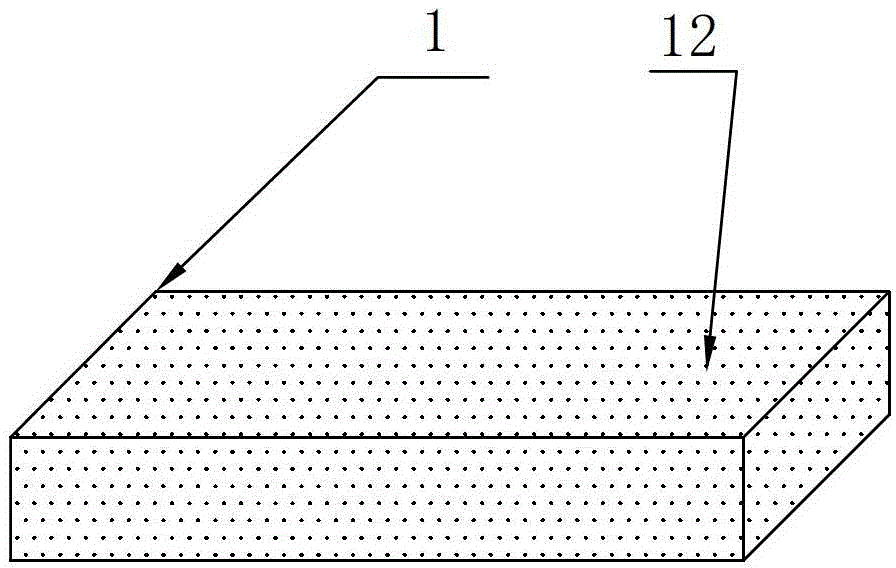

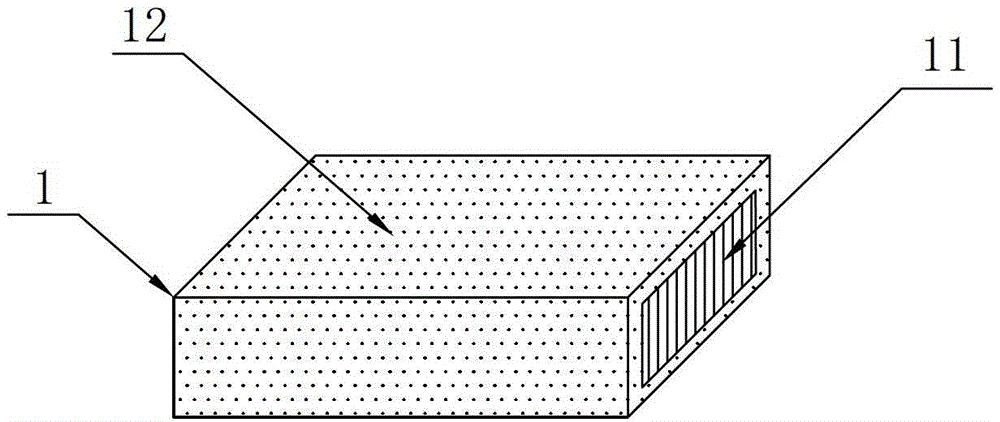

[0020] figure 1 It is a schematic diagram of the structure of the colored microcrystalline brick fired once in the present invention, figure 2 It is a schematic diagram of the cross-sectional structure of the once-fired colored microcrystalline brick of the present invention, consisting of figure 1 as well as figure 2 It can be seen that the once-fired colored microcrystalline brick 1 of the present invention includes a brick body 11 and a decorative layer 12 .

[0021] The decorative layer 12 covers the surface of the brick body 11 .

[0022] The thickness of the decoration layer 12 is 1.70±0.5mm.

[0023] The decorative layer 12 can be toned and can also protect the adobe body 11, so that the whole once-fired colored microcrystalline brick 1 is both beautiful and practical.

[0024] The production process of the one-shot colored microcrystalline brick of the present invention is as follows (component content is in mass percentage):

[0025] The first step: make the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com