Annular rubber-sheet cooling machine

A film cooling machine, ring-shaped technology, applied in the direction of conveying objects, winding strips, sending objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

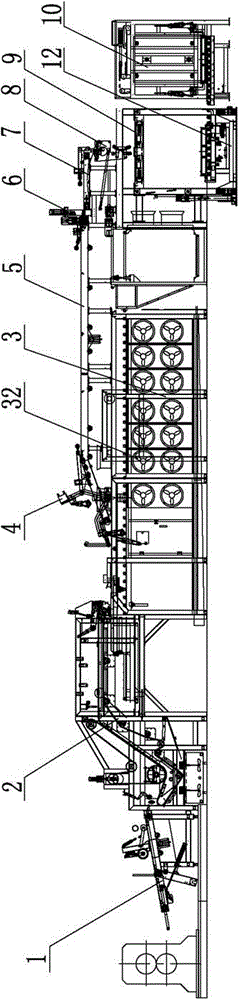

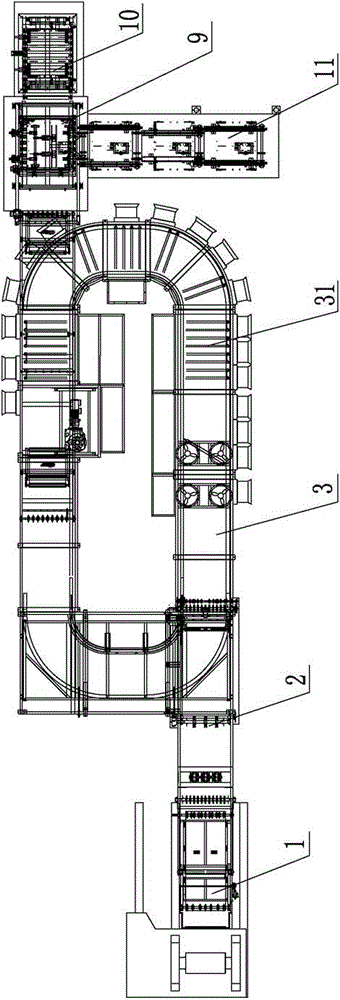

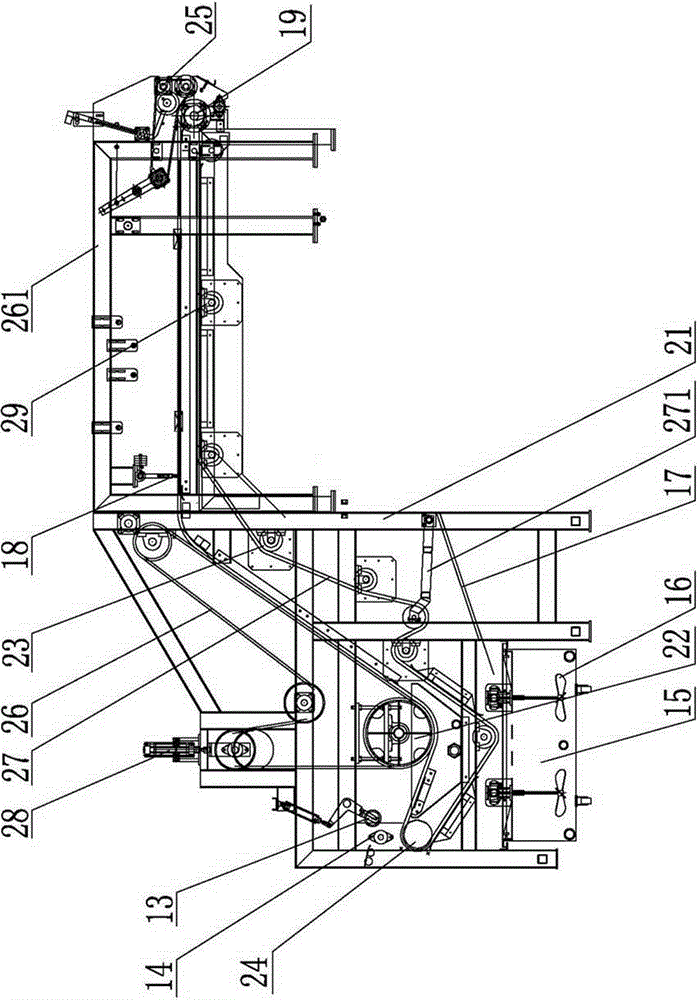

[0028] Please refer to appendix 1 to appendix Figure 7 As shown, the present invention is a ring-shaped film cooling machine, which is composed of a receiving device 1, a lifting conveying device 2, a glue-hanging cooling device 3, an automatic gripper 4, a skin-receiving conveying device 5, a film cutting device 6, and a lower skin-receiving device. Conveying device 7, automatic swinging glue stacking device 8, lifting table device 9, empty glue tray automatic input device 10 and full glue tray automatic output device 11 are composed of several parts.

[0029] Wherein, the receiving device 1 , the lifting and conveying device 2 and the glue-hanging cooling device 3 are arranged sequentially. The automatic gripper 4 is arranged on the top of the glue-hanging cooling device 3, and it is sequentially connected with the leather-receiving conveying device 5, the film cutting device 6, the lower leather-receiving conveying device 7, and the automatic pendulum glue-stacking device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com