Novel pump impeller

A technology for pumps and impellers, which is applied in the field of new pump impellers, can solve the problems that centrifugal pumps are not easy to carry, increase the complexity of centrifugal pump structures, etc., and achieve the effect of light structure, simplified structure and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

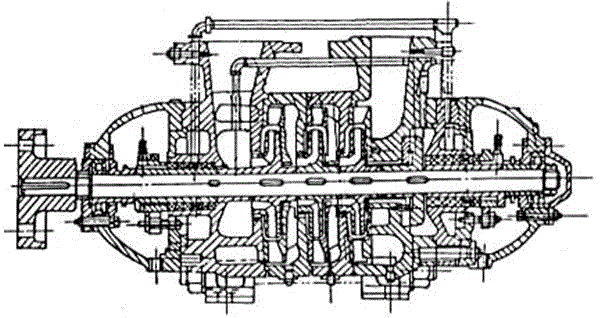

[0014] The present invention improves the structure of the existing impeller by designing a new type of pump impeller, so that the drainage pump can achieve a high lift with a single impeller, so the impeller described in this patent does not need to be installed on the power output shaft of the engine without a coupling It can be used directly on the screen, which greatly simplifies the structure of the centrifugal pump.

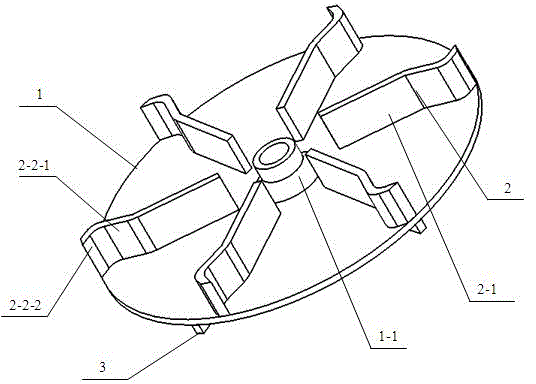

[0015] As a specific embodiment of the present invention, the present invention provides a structural schematic diagram such as figure 2 A new type of pump impeller shown includes a cover plate 1, a front blade 2 and a rear blade 3. There is a connecting portion 1-1 in the middle of the cover plate 1, and the portable pump impeller passes through the connecting portion on the cover plate 1. 1-1 is installed on the power output shaft of the engine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com