Impeller of compressor

A compressor impeller and blade technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems affecting the aerodynamic performance of the impeller and reduce stress concentration, so as to improve the economy of the impeller, reduce stress concentration, and reduce the impeller The effect of material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

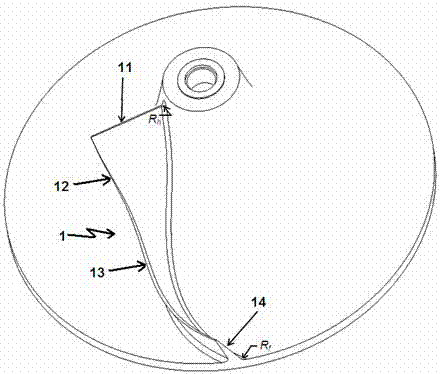

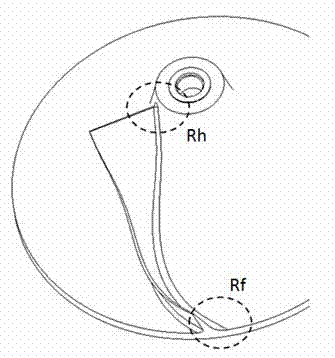

[0010] The invention provides a compressor impeller, which ensures the aerodynamic performance of the compressor impeller blade and makes the aerodynamic performance of the impeller close to the theoretical design value. At the same time, the stress concentration of the impeller is reduced, thereby reducing material requirements and improving economy.

[0011] In the following, the compressor impeller provided by the present invention will be further described in detail through the examples, so as to better understand the content of the invention, but the content of the examples does not limit the scope of protection of the invention.

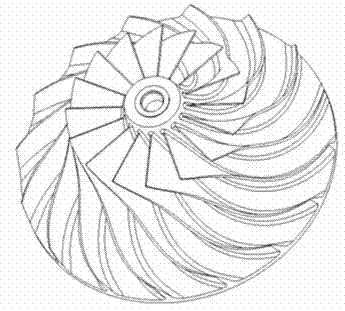

[0012] Such as figure 1 and figure 2 As shown, the impeller of the compressor is composed of a turntable and a plurality of blades 1 installed on the turntable. The blade 1 leaves the center of the turntable in the radial direction and protrudes outward along the surface of the turntable, and the connection between the root of the blade 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com